PPE for wiring are spring-type connecting insulating clamps. They are used for the safe connection of cables and wires of different diameters. The main advantage, thanks to which PPE has become an integral attribute for an electrician, is high-quality insulation. It takes less time to complete and does not require special skills or a set of tools.

Advantages and disadvantages

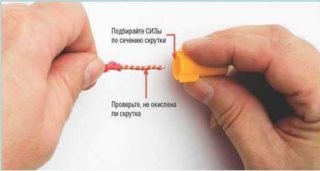

In order for the resulting twist to be reliable and durable, it is important to ensure maximum contact between the conductive cores - press them tightly and tightly to each other. The clamp is equipped with a small spring that enhances the effect. The metal spring has its own service life, over time it will weaken and the contacts with it, as a result, the wire will begin to heat up.

There are many methods of isolation, but the leading position is occupied by the use of electrical PPE. This is due to a large number of advantageous features.

- High-quality products operate in a wide temperature range, namely from -40 to +105 degrees Celsius.

- Simplicity and ease of installation - this approach saves time and budget by not having to stock up on a set of tools.

- No additional insulation materials are required.

- PPE insulating caps for twisting wires perform several functions - they insulate and protect electrical lines from mechanical, chemical and thermal effects.

The result is a reliable, durable and practical connection. If necessary, you can redo it or completely disconnect the wires.

Despite the large number of advantages, there are also disadvantages:

- For safety reasons, it is not recommended to use PPE as the only isolation method, in its pure form.

- It is important to ensure that the size of the clamp matches the section of the wire or cable.

- It is allowed to connect only copper conductors. If it is required to connect an aluminum wire, then the PPE must be additionally equipped with antioxidant paste.

Another disadvantage is that it cannot be used to install street lines.

PPE design for twisting wires

The spring is made of steel, it has the shape of a cone, the wire is clamped more tightly due to the turns. This part is additionally treated with an electrochemical protective layer.

How to choose PPE

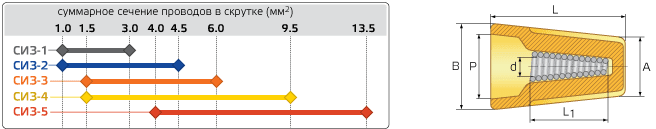

Small designs are required to be selected by wire cross-section. To do this, add up the cross-section of each wire and compare the resulting number with the data in the table below.

Standard size | The sum of the cross-sections of the wires to be connected | Voltage | |

| minimal | the maximum | ||

| PPE-1 | 1 mm sq. | 3 mm sq. | 300 V |

| SIZ-2 | 4.5 mm.kv | ||

| PPE-3 | 1.5 mm.kv | 6 mm sq | 600 V |

| SIZ-4 | 9.5 mm2 | ||

| PPE-5 | 4 mm sq | 13.5 mm2 | |

Varieties

Before going to the store for electrical clamps, it is recommended that you first familiarize yourself with their varieties.

- Standard smooth models - closed caps, spring-loaded, tapered, no “ears” or other accessories.

- Clamp with screw tightening - not a spring is used here, but a special screw, the tightening of which can be manually adjusted from the outside.

- Insulating PPE with two holes. As a rule, such structures are used to connect grounding electrical lines. The cable is routed through the top hole to the switchboard or electrical appliance.

- Silicone-filled waterproof constructions are clips that protect electrical wires from moisture. Most often used outdoors and in high humidity conditions.

- Antioxidant Clamps are a versatile design that allows copper and aluminum wires to be connected together.

- Low profile caps are compact parts designed to work in confined spaces.

There are PPE caps with and without ears. They have no special differences, the only thing is that it is easier to wind the part with ears onto the cable, and PPE without them takes up less space in the junction box.

Installation methods

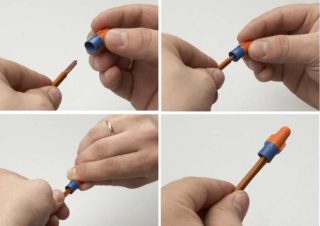

There are two ways of twisting with caps: with and without preliminary twisting of the cores. If it is necessary to connect two cables or wires, it is enough to insert them into the spring, applying force. If the wires have three or more cores, they must first be twisted together using pliers. After the uneven ends of the wire are bitten off and with rotational movements they are placed in the PPE clamp.

Winding should be done clockwise, not counterclockwise, otherwise full contact contact cannot be achieved.

The plastic body of the cap insulates the junction and protects the conductors from mechanical stress. If the work has been done correctly, additional insulation is not required.

Some helpful tips

- It is not necessary to cut the insulating material from the cores to a great length. It is important to pre-match it with the inner length of the tapered cap.

- If the caps are the wrong size, they will fall off the twists as a result, leading to overheating of the wire and possibly a short circuit.

- The color solutions of the structures are not classified or negotiated in any way, so the electrician serves the connection points as it is convenient for him.

- It is forbidden to use connecting insulating clamps to connect aluminum and copper wires. For these purposes, there are a large number of devices, for example, special adapters with metal plates, terminal blocks and self-clamping terminal blocks.

It is important to check the functionality of the cap and the quality of the connection. To do this, the maximum possible voltage is applied to the wire or cable for at least half an hour. If after this time the PPE has not heated up, the connections are made as expected, otherwise it is worth repeating the procedure.