220V LED strip is a board based on flexible insulating material. Conductive strips are applied along its entire length, between which groups of LEDs and a current-limiting resistance are located. All elements of the tape are connected in series and placed in a transparent plastic case. The variety of LED strip designs is due to the size and number of LEDs in a group and on a 1 meter segment. All of these features affect the power and brightness of the emitted light.

- Varieties of models of LED strips for 220 V

- Advantages and disadvantages

- Installation of LED strip

- Devices for connecting LED strip to 220 V

- Switching power supplies

- Transformer 220/12

- Current limiting capacitor

- Serial connection

- Diagrams for connecting LED strips to a 220 V network

- The length of the tape is more than 5 m

- A dimmer must be connected to the network

Varieties of models of LED strips for 220 V

Depending on the purpose and features of the LED strip, LEDs 3528, 5050, 2835, 3014 and 5630 can be used in it. Modifications 5050 and 3528 are the most widespread, the rest are less common and are usually ordered from Asian suppliers.

Among the main parameters of 220 V LEDs, it is worth noting:

- Possibility of multiple cutting in 50 cm increments - 50, 100, 150, 200 cm, etc. Attempting to cut off a smaller amount will ruin the device.

- Power per meter.

- Degree of protection against high ambient humidity.

- The color temperature of the emitted rays.

In addition to standard strips with white glow, RGB models are produced with red, green, blue and yellow lamps. In general, they are three single-color LEDs with different shades, which have a common contact for power supply and different contacts for dimming the lighting. To connect such a lighting device, a 220 V RGB controller is required.

The protection grade of LED lighting can be IP67 or IP68. Thanks to the dense silicone tube housing, the lighting device can be operated in extreme humidity conditions at any ambient temperature. Depending on the degree of rigidity of the base, the tape can be used as an independent lighting unit or as separate modules, from which unique designs of lamps are created.

Some models of LEDs are produced with an adhesive strip based on acrylic tape, which significantly speeds up the laying and fixing of the segment.

Advantages and disadvantages

Among the advantages it is worth noting:

- Possibility to connect without power supply.

- Quite good power - a 10 m fragment gives 70 W illumination with minimal power consumption.

- Low installation costs due to the use of thin wires for low amperage.

Limitations on the use of LED strip can be caused by the following factors:

- the complexity of the repair due to the sealed shell;

- cutting only for multiple lengths, which may be unnecessary or insufficient for a particular object;

- flicker frequency 100 Hz, which, with prolonged exposure to lighting, can cause a deterioration in well-being;

- voltage 220 V, requiring special attention during installation and operation of the tape.

The recommended area of application of LEDs is auxiliary or backup illumination of premises of houses and apartments: a kitchen, a bathroom or a sauna, a corridor or a garage.It is also possible to use it as a decorative element - for highlighting buildings, advertising signs, elements of decorative structures and sculptures, stage decoration, etc.

Installation of LED strip

In the process of connecting the tape, a number of requirements should be taken into account:

- the connection of the fragments should be carried out taking into account the polarity;

- it is allowed to connect sections using connectors or by soldering when exposed to the tape for no more than 10 seconds at a temperature of no higher than 260 degrees;

- the tape for external mounting must have high-quality moisture protection;

- the surface for laying and gluing the tape must be dry, grease-free and clean;

- the minimum bending radius is 2 cm, with the exception of a single bend in an area where there are no electronic components;

- serial connection is possible only for segments up to 5 m long; for longer segments, a parallel connection scheme is used.

The operating temperature range for LEDs is from -40 to + 50 ° C. The service life of the tape is 50,000 hours without reducing the brightness of the glow.

Devices for connecting LED strip to 220 V

For tapes with voltage less than 220 V, connection directly to the outlet is excluded. Due to the high voltage, the LEDs will instantly burn out. Therefore, the connection to the power supply is carried out using auxiliary devices:

Switching power supplies

Quite expensive, but the most reliable option. The power supply provides a stable voltage and eliminates light flickering due to current ripple. The new generation PSU models are equipped with dimmers and remote controls, which allows you to adjust the brightness of the lighting from a distance. As a valid alternative, you can use a power supply unit from the computer system to connect the LEDs.

Transformer 220/12

The device consists of a step-down transformer, a capacitor and a rectifier bridge. In it, the voltage is reduced and equalized by smoothing the ripple. It is possible to independently manufacture a transformer from an old receiver or tube TV. It is necessary to wind a 12V secondary winding on the base model and assemble the model together with a diode bridge or capacitor.

Current limiting capacitor

The method is suitable only for connecting small pieces of tape to the network, which are intended to act as a night light or bedside lamp. If you increase the length of the segment, the power consumption of the unit will increase, the use of economical LEDs will be impractical. In addition, the excessive consumption of 220 volt electricity by the power supply makes it necessary to take additional electrical safety measures.

Serial connection

This method allows you to refuse to use the power supply, but in return requires compliance with certain conditions. The total number of LEDs along the length of the available segment should be a multiple of 60, which will allow the strip to be divided into 20 equal parts. All segments must be the same and have an equal number of LEDs. Otherwise, the voltage will be unevenly distributed, some of the fragments with excess power will quickly burn out.

The serial connection of the structure is carried out through a diode bridge and a capacitor.

Diagrams for connecting LED strips to a 220 V network

If the strip is made of SMD 5630 LEDs, its power consumption is greater than 10W per meter of length. Installation of such a tape is carried out on a metal base for efficient heat dissipation. Flickering of light, which negatively affects a person's well-being, can be completely eliminated by connecting a capacitor to the lighting network.

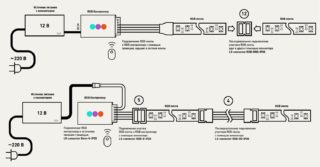

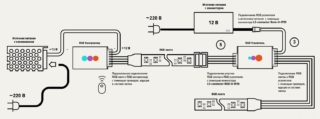

The connection of a 220 V RGB color LED strip is carried out through an RGB controller that controls the brightness and light of the strip.According to the standard scheme, the controller is connected to the low-voltage output of the power supply. Then the LED strip is connected to the corresponding terminals of the controller. Of the four wires, three are for color control, and the fourth is required for power supply. Restrictions on the length of RGB tape - no more than 5 m for each segment. Parallel connection of two 5 m sections to a powerful power supply unit is possible.

The high power LED strip is connected using AC / DC converters. This method is not only very simple, but also economical in terms of costs, and also very convenient in operation.

The general connection diagram is as follows:

- Fragments that are multiples of 50 or 100 cm are cut from the tape.

- A layer of sealant is applied to the cut edge and a silicone connector is put on, which is also attached to the sealant.

- The wire is connected from the rectifier.

- The lighting is checked for the functionality and tightness of the protective layer.

The following connection options require special attention and careful installation work:

The length of the tape is more than 5 m

Serial connection of segments in this situation is excluded. As you move away from the power source, the voltage will drop, and the last sections will receive less power, resulting in a weaker light. If the voltage is increased, the load on the belt will increase and its service life will be sharply reduced.

It is recommended to connect the lengths in parallel using wires with a cross section of at least 1 mm. You will also need one powerful power supply unit or several models of power supply units of lower power, the supply wires of which are connected in parallel.

A dimmer must be connected to the network

The light dimming device is connected to the network between the power supply and the LED strip, correctly placing the input and output contacts: the first to the power supply, the second to the light source. If you need to connect several segments to the dimmer at once, the total power of which is higher than the power of the regulator, it is recommended to use a signal amplifier.

Provided they are properly connected, LEDs will be an excellent alternative lighting option that does not require large installation and maintenance costs.