The grooves are grooves made in the walls. They are used for laying electrical and engineering networks. It is necessary to fix the wire in the strobe in order to protect it from mechanical damage, preserve the aesthetics of the interior. In solid and hollow surfaces, holes are made with special tools, and the cable is fixed in several ways.

- General rules for fastening the cable in the strobe

- How to fix the wire in the strobe

- Alabaster

- Dowel clamps

- Dowel-ties

- Dowel clips

- Cable ties for dowels

- Plastic dowel for screed

- Aluminum plates

- Fasteners for organizing the conductor bundle

- Homemade gadgets

- How to lay the wire

- Closed technology

- Using an open way

General rules for fastening the cable in the strobe

Safety regulations state that in residential, public buildings and in production, it is necessary to install wiring with non-combustible insulation or in a solid metal box. Experts provide several universal recommendations:

- the main task of fastening is to ensure the reliability of fixation without sagging;

- at the turns of the track, fasteners can be removed 5-10 cm from the bend point;

- screws, self-tapping screws and dowels are tightened to stop - so the protruding head will not damage the insulating layer;

- fastening is carried out with a maximum distance between the points of 50 cm;

- styling is done strictly along a vertical or horizontal line, the stock is masked;

- the wire before plastering is positioned so that it does not interfere with the application of coatings;

- in the presence of a stretch or false ceiling, the slitting is not performed;

- use a drill, puncher, hammer and screwdriver for installation.

The supply of cable can be rolled into a ring.

How to fix the wire in the strobe

After the preparatory work, you will need to think about how to securely fix the wire laid in the strobe. There are several methods.

Alabaster

Building gypsum mixture is used if it is necessary to fix the wiring in the furrows. Alabaster will hold up well with a minimum of soft-insulated cables. The composition is applied in small portions. The disadvantage of this method lies in the quick setting of the mixture, so it cannot be prepared in a large volume.

Dowel clamps

The products are produced in black and white for cable diameters of 19-15 mm, 5-10 mm and 11-18 mm. The polyamide fastener is 6 mm in diameter and is a loop with latches at the lower ends. Before using the dowel clamps, you will need to make a groove with a puncher, install fasteners and fix the wiring. The disadvantage of this technology is the strict selection of the cable diameter to the size of the dowel-clamps.

Dowel-ties

The product looks like a dowel-nail, combined with a cable tie, is made from self-extinguishing plasticizers. Dowel-ties are equipped with split and one-piece locks. In the first case, the master can add or remove wires. It is used for open and hidden installation of a single or bundled cable line on brick, concrete and other surfaces.

To attach the wire with a dowel-tie, you will need to put a tie in the drilled grooves and fix its expanding peg. A cable is laid in an open product. The tie is pressed.

Dowel clips

Suitable for open installation of communications on drywall or for retro-finishing.The fastener is a curved plastic strip with elastic branches at the ends. These elements hold the retainer. The clips are suitable for mounting a flat or round conductor with a small cross-section (television, telephone, Internet connection).

Installing the dowel clip is easy. You will need to drill a niche of the required diameter, insert a tourniquet into the clip, tucking its ends into the hole. The element is inserted into the hole with force. Electrical communications look neat and do not interfere with operation.

Cable ties for dowels

Modifications in the form of a threaded dowel and a screed plate. A non-combustible plastic or nylon element can be easily attached to aerated concrete, wood, brick or concrete walls. Compatible with screws, screws, self-tapping screws, standard and dowel-nails.

Before installation, it is necessary to make a hole for the diameter of the fastener. First, a dowel is placed, then the cavity in the screed and base is combined. Then the screed-platform is clogged and screwed on, and the wires are laid on the finished track.

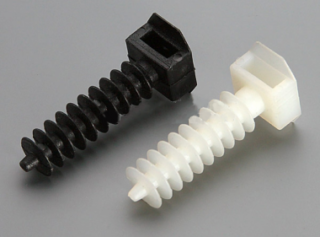

Plastic dowel for screed

Polyamide screed dowels with a rectangular hole head allow you to fix the wire without any problems. The element will need to be hammered in, and then the wire is pulled through the head. It will be securely and firmly fixed in the strobe.

Aluminum plates

Thin metal cut strips are most commonly used. Several cables are twisted with a plate, which is then drilled through and attached to the bottom of the groove on the dowel-nails.

The strip is pierced exclusively in the center, and the cable strips are laid on top of it. After placing the wiring, the ends of the box are bent.

Fasteners for organizing the conductor bundle

Not all types of wires are fixed permanently. Problems arise when equipping a workplace where it is necessary to carry out lighting, the Internet, connect a PC. Special wire holders exclude holes from nails and screws, allow you to quickly transfer communications. There are several types:

- Cable clip with double-sided adhesive tape on the back. Suitable for installing wires on furniture or plastic panels.

- Installation site. To fix the wire, first fix the pad with the sticky part. The bundle is attached to the holes with a standard tie.

- Cable trays. They are made of galvanized wire or perforated metal. They are used if you need to fix the wires to the ceiling.

The trays can be used in contact with combustible materials.

Homemade gadgets

If there is no specialized fastener at hand, home craftsmen use the material at hand:

- Dowels or nails. Fastening is done before the start of laying the wires. A dowel or nail is punched in the center of a piece of telephone cable and screwed on the other.

- Corrugated hose. You will need a piece longer than the width of the line. The corrugated hose is compressed slightly and placed in the groove. Fasteners can be removed as the plaster layer is applied.

- Perforated stripes. The technology is suitable for Khrushchevs and provides for fixing the segments with perforation with dowels across the pipe. In this way, you can attach bundles of wires.

- Galvanized sheet staples. Cut the material into strips 1 cm thick and bend the staples. The products are suitable for fastening cables to walls and ceilings. They are positioned in 50-80 cm increments and are fastened with nails.

Homemade fasteners are easy to manufacture, save money on the purchase of special consumables, are installed many times, and high-quality fixes a single wire and a bundle.

How to lay the wire

The surface is channeled before the cable is laid.They work with a perforator with a special nozzle-strobers in the form of a curved shovel with a groove. The standard paddle also allows for deep coverage. The cuts to the desired depth can be made with a grinder, and the central parts can be knocked out with a puncher.

Closed technology

Most often, the wiring in the strobe is carried out in a hidden way. The strobe is organized if the room has not yet been finished.

Cable products can be fixed:

- screeds - dowel or assembly pads;

- clips for the size of the section;

- on suspensions or inside ceiling profiles made of gypsum plasterboard;

- in trays when stacking multiple bundles.

At the stage of repair work, the wire can be laid inside the walls, floor or ceiling.

Using an open way

The conductors should be fastened in such a way as to preserve the aesthetic appearance of the finish. There are several tricks for this:

- cable channels - plastic trays fixed along the wall surface;

- special skirting boards - wood-like texture will perfectly fit into the interior;

- staples and clips - installed with a stapler, painted to match the wiring.

Open wiring is suitable for loft, retro or Provence spaces.

After laying the cable, dust and debris are completely removed from the strobes, they are passed over them with a special primer. After waiting for the product to completely dry out, the strobes need to be plastered, and after a while, putty. Compliance with safety measures and the correct selection of fasteners exclude damage to the wiring during the decoration and operation.