In the range of modern ceiling and wall lamps, models equipped with linear (tubular) lamps are represented quite widely. They are installed not only in offices, factory halls and public places, but also in residential areas. In everyday life, they are often used to illuminate aquariums and other special areas where diffused light is needed. Not so long ago, only fluorescent illuminators (LL) were used as a source in them, but today they have been replaced by a more advanced T8 LED lamp. It is useful for users to find out which of these two options is better and what needs to be done to replace the LL with an LED analogue without changing the body of the luminaire itself.

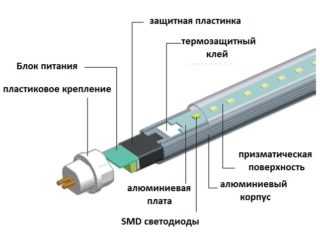

Construction and plinth

Typical T8 lamps are manufactured in the form of a tube with a diameter of 25.4 mm, at the ends of which there are pins spaced 13 mm apart. Together with the end cap of the tubular bulb, they form a base through which the operating voltage is supplied, while simultaneously fixing the product in the luminaire body.

The most popular tube designs are 600 and 900 mm long. Luminaires equipped with two lamps of this length are installed everywhere. Products offered on the market with long fluorescent tubes of 1.2 and 1.5 meters are much less common and are used mainly in industrial facilities and, if necessary, to illuminate large spaces.

Miniature fixtures of irregular length are used for local lighting, providing the user with comfort and coziness.

Types and characteristics of lamps

There are two classes of T8 standard tubular products on the domestic market. These are fluorescent and LED light bulbs. Despite the apparent similarity of different types of tubes, their principles of operation differ radically.

Fluorescent lamps T8

This type of lighting fixture is the most common example of a group called "fluorescent lamps" or LDS. Their flask is filled with mercury vapor, which, when ignited by a glow discharge, emit ultraviolet radiation, which is close to a blue glow. It acts on the phosphor, which is applied from the inside of the flask during the manufacture of the flask. As a result, the coating begins to glow, and the part of the UV spectrum harmful to the eyes is absorbed in the body of the glass tube.

To start and maintain combustion, two spiral electrodes are used, the voltage to which is supplied through the G13 connectors at the ends of the tube. To control the flow of the discharge in the flask, which should not turn into an uncontrolled arc process, the current through the gap is limited by taking special measures. For this, an electronic or electromagnetic control device ECG (the so-called "ballast") is used, at the same time providing an easy start of the light bulb. This work unit, built directly into the luminaire, is designed to work with two tubes of 18 watts each.

T8 LED lamps

In contrast to LL, mercury and phosphor are not used in LED tubular fluorescent lamps, the radiation is formed by semiconductor LEDs placed inside the bulb.Their total number is determined by the requirements for obtaining the desired light output (radiation power), and also depends on the dimensions of the luminaire. There are two types of LED illuminators with a typical size of T8:

- Models with a built-in driver.

- Products that can work without it.

The former do not need additional devices, which allows them to be connected directly to a 220 Volt network. The second type does not contain a built-in driver, so a separate power supply is needed for their operation. With its help, it is possible to convert variable 220 volts into a voltage suitable for powering LEDs.

Which illuminator is better

To choose the appropriate option, you need to compare the merits of the models, and then make a final conclusion. The comparison results can be presented as follows:

- the main advantage of T8 LL tubes (their efficiency and durability) are more than covered by their LED counterparts;

- to power fluorescent products, starting equipment is required, the cost of which is comparable to the price of an LED lamp;

- Electronic ballasts very often fail, and this implies additional costs;

- the main disadvantage of LED lamps - their high cost - eventually fades away, since semiconductors quickly become cheaper with an increase in the mass of goods produced.

In modern conditions, it is preferable to purchase LED tube fluorescent lamps, the dimensions of which are no different from those for LL.

As an exception, a situation is considered when it is impossible or very difficult to change fluorescent lamps for LED counterparts due to the peculiarities of their design.

Replacement of T8 fluorescent lamps with their LED counterparts

The tubes of these lamps have the same dimensions and are equipped with identical connectors. This similarity greatly simplifies their replacement and connection, which are made directly in the luminaire. In this case, if you have a ready-made body product, it is enough to buy an LED sample and put it in the place of the old lamp.

Seat selection

You can't just take and remove one lamp from the lamp socket and then put another in its place. In addition to this, it will be necessary to change the electrical circuit, which is provided for in the design of the existing lighting device. Despite the fact that some users find it difficult, anyone who is familiar with the basics of electrics can update the electrical filling.

First of all, you need to understand how the LED lamp is connected to the network. It is connected in two ways, depending on the version:

- in the first case, the voltage is applied to the right or left base (on one side) to both pins at once;

- in another version, the power cable is connected from both sides of the tube to different sockets, in which only one pin is involved.

Early products usually did not have a built-in driver in their designs. The samples of the second type have an electronic control circuit that allows them to be connected directly to a 220 Volt network.

The assortment of individual manufacturers includes models that can be connected to the network, regardless of the presence of a built-in driver. Before buying, you should check with the seller how the lamp is switched, and also find out what supply voltage it is designed for.

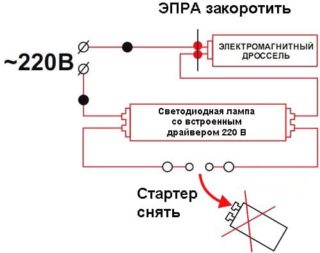

Connecting a T8 LED lamp

\

The easiest way is to replace the LDS with an LED analog if the new lamp already has a built-in driver. In this case, you will have to perform the following simple operations:

- Pull the starter out of the socket.

- Short-circuit the electromagnetic choke.

- Since it does not participate in the power supply process, it is allowed to completely dismantle it from the lamp.

- As a result of these actions, a voltage of 220 volts will be supplied to the pins of the socles located at different ends of the lamp.

When only an LED sample without a driver is available, this electronic device will need to be purchased. We'll have to slightly modify the scheme of a standard fluorescent lamp:

- One conductor going from the 220 Volt network to the electromagnetic choke is disconnected.

- The disconnected end is thrown over to the driver terminal to which the starter removed from it was connected.

- All mains voltage will be applied to the electronic device that controls the operation of the LED lamp.

For everyone who is familiar with electrical engineering at the level of the school curriculum, these simple operations will not be difficult.

Selection recommendations

When buying an LED lamp, attention is drawn to its color temperature, which is measured in Kelvin (K) for devices of this class. Not only the state of health of the person using it depends on this indicator, but also the comfort of the resulting lighting. It must be indicated in the accompanying documentation for the purchased product or applied directly to the packaging.

Only after becoming familiar with the features of the device and operation of the LL and LED lamps, they take up the procedure associated with their replacement. This avoids unnecessary costs for the purchase of a new luminaire.

I don't shine