To save space in corridors and living rooms, a two-key pass-through switch is used. The device increases the comfort of controlling light sources from several points. Before starting the installation, it is worth designing the location of the wiring and focusing on the geometry of the room.

- Features of the two-key switch

- Design differences

- How the 2-key PV works

- Scope of use

- Varieties of devices

- By installation method

- By the type of operation of the key spring

- By the method of switching elements

- Connection diagram

- Connect two devices from two points

- Sequence of actions and general requirements

- Tools and materials

- Cross-section of the power cable by the power consumption of the group

- Two-gang switch connection for 2-point control

- Features of desoldering two-key PV

- Major mistakes when setting switches

Features of the two-key switch

The two-rocker switch is connected to the lighting circuit through the second changeover contact of each switch with two cables in between. In fact, the device is a dual one-key model with four wires. The electric circuit of each core is an autonomous element of the lighting line that provides power to a specific lamp without interacting with other parts.

Depending on the brand, there are from 2 to 4 terminals at the inputs and outputs of the device. For example, switches are produced with 1-phase terminal, 1 output terminal per bulb, 4 terminals for intermediate cables.

The convenience of two-key models is the ability to activate light from different corners of the room.

Design differences

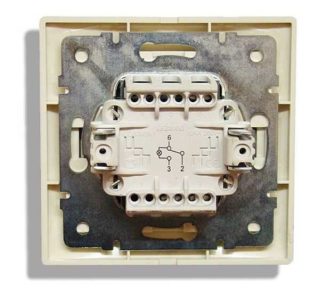

Structurally, DPV is stationary contacts of the body and the movable spring rolling mechanism. A plastic or ceramic frame is used for fixing the contact terminals and for switching. The device has 4-6 contacts, some brands number them.

The toggle switch is made with two keys without standard designations, but its dual purpose can be judged by the multidirectional arrows. The buttons in a single body are distinguished by the independence of the circuits, which ensures the control of two lines of illumination. Closing the electrical circuit is carried out autonomously with 2 buttons.

How the 2-key PV works

The functionality of a double switch is similar to that of a single switch. The main difference is in the connection of two identical elements in one housing, which expands the capabilities of the device. When you press the switch button, the contacts are flipped, the circuit is closed and the light is turned on. Disconnection, i.e. switching in reverse order opens the circuit.

Manufacturers indicate the algorithm for switching on the light on the keys with arrows.

Scope of use

Due to the switching capacity of 16 A, the installation of a double feed-through switch is only allowed for line control with a load of up to 3 kW. The device is used:

- to control the light in the bathroom and toilet from one element;

- adjusting the brightness of the lamp on the chandelier;

- switching on / off the LED strip of the stretch ceiling;

- activating and deactivating nightlights;

- creating lighting in a room with several lamps;

- group control of bulbs in halls and corridors.

The use of double switches provides savings in wire routing to single models.

Varieties of devices

Before connecting the DPV, you need to understand the classification.Knowledge of installation features, type of activation will help you choose the right switch.

By installation method

There are two types:

- Internal, or "recessed". They are located in the wall as a hidden wiring element. The cable is laid in the groove or inside the gypsum board. To connect the switch, you will need to additionally put a socket for the working part in the hole. Mounting grooves are connected to it.

- Outdoor. They are installed in the case of laying wires in a corrugation or a box over a wall. They do not fit in boxes on porcelain insulators. Outdoor switches are justified in wooden dachas, outbuildings and utility rooms.

Use outdoor models for temporary wiring.

By the type of operation of the key spring

The two-rocker switch functions according to the following principles:

- Compression: When the button is pressed, force is applied to the ball, which compresses the spring. The element slides along the rocker arm swing axis, and moving along its shoulder, provides movement of the active node with contacts.

- Stretching: there is a frame on the key pressed against the base of the spring. The part wobbles along an axis, breaking or creating an electrical contact.

The active part is switched regardless of the mechanism.

By the method of switching elements

DPV can be connected using screw or screwless terminals.

When installing on screw terminals, the main difficulty of the work is the lack of pin marking. To find the entrance, you need an indicator screwdriver. The phase sockets are located at the top of the ceramic body. Remove the insulation from the 0.7 cm wires before connecting.

The phase is brought to the upper contact by inserting the stripped section into the gap formed when the screw is unscrewed. The two remaining contacts are connected in the same way.

For screwless models, the conductor contact is carried out using conductive fittings. An insulating layer is removed from the wire 8-10 cm in length. The phase conductor is thrown onto the input contact at the top of the panel. It is identified by marker 1 or L.

The stripped part of the wire is placed in a special opening. The fixation takes place by means of an internal spring assembly. The rest of the conductors without insulating cover are installed in the sockets for the output contacts.

The screw terminals need to be tightened periodically.

Connection diagram

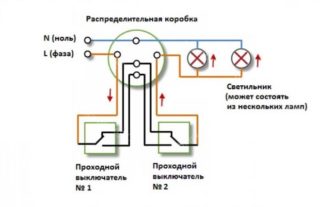

The standard wiring diagram for a two-key pass-through switch provides for the presence in the room:

- distribution box 10-30 cm below the ceiling line;

- the main device - DPV;

- lamps in two rooms.

After installing the equipment, it must be tied into a single system as follows:

- Switch off the opening apartment machine.

- Find a two-core cable with zero and phase in the junction box.

- Lead the phase wire from the junction box to the fixed contact of the input.

- Connect the fixed tap-off contacts to the lamp holders with two more phase conductors.

- Put the phase conductor on one contact of the cartridge, on the second - zero and connect it to the power supply zero in the junction box.

Connection of input contacts is allowed only with phase.

Connect two devices from two points

The scheme provides for the arrangement of two groups of light bulbs at the beginning and at the end of the room for easy control. In order to save cable, the junction box is placed next to the shield.

Sequence of actions and general requirements

The step-by-step installation algorithm provides for the selection of a wire with the calculation of the cross-section and length, the connection of wires, the desoldering of the structure.

After cable selection:

- A puncher drills holes in a brick or concrete surface. They work with a crown, departing 15-20 cm from the ceiling.

- In the vertical direction, at a distance of 60-90 cm from the floor surface, a niche is drilled for the 1st socket.

- On the opposite side, a groove is made for the second socket.

- A cable with a large cross-section is laid from the switchboard to the distribution box.

- A line of 2 wires with 3 cores is organized from the box to the switches. Their cross section should be smaller.

- For the line of lighting devices, three-core cables are used, laid according to the diagram.

- Loops are made of 30-40 cm under the shades.

- The ends of the cable are laid in the junction box and in the socket.

- The housings are placed in niches and mounted on a plaster mix.

After the gypsum has solidified, the insulating layer is removed from the ends, the wire is connected, the lamps and sockets are connected.

Tools and materials

For installation, you will need to purchase a distribution box, 2 internal sockets for a concrete and brick wall, 2 DPV devices, lighting elements. Installation of switching devices is carried out using pliers, a level, wrenches, wire cutters, a clerical knife, a screwdriver, terminal blocks, electrical tape.

Cross-section of the power cable by the power consumption of the group

The installation of a double switch is carried out using a 6-core wire. It is allowed to use a different type of marking - VVG, PUNP, VVP, MYN, but only with double insulation and copper conductors. The section of the products is selected in accordance with the table.

| power, kWt | Current, A | Length, m | Section, mm2 |

| 1 | 4,6 | 34,5 | 1 |

| 2 | 9 | 17,5 | 1 |

| 3 | 13,5 | 17,5 | 1,5 |

| 3,5 | 16 | 24,5 | 2,5 |

| 4 | 18 | 21,5 | 2,5 |

| 6 | 27 | 23 | 4 |

| 8 | 36,5 | 25 | 6 |

The discrepancy between the length, total power and cross-section of the wire will lead to overheating of the contacts and damage to the network.

- neutral - blue or light blue;

- grounding - yellow-green;

- phase and points of its commutation - black, red.

Sometimes it is allowed to use a white phase.

Two-gang switch connection for 2-point control

It is advisable to implement a wiring diagram for a two-key pass-through switch for 2 points before work on the interior decoration of the room. It is performed step by step:

- Making strobes - one from the PV to the junction box, two - in the opposite direction, one - from the junction box to the lighting fixtures.

- Selection of conductors for the section from the distribution box to the first switch. 2 cables with 3 cores or 3 cables with 2 cores will do.

- Feeding two cores to supply voltage to the first switch, and the remaining four to the second through the junction box.

- Connection to the second DPV in the groove of 3 two-core cables. Two wires should be directed to the light sources, the remaining 4 to the first switching device.

- Connecting 1-2 neutral conductors to the lighting device.

- Laying the two-core power cable to the junction box.

Select the size of the box so that it fits at least 16 wires.

Features of desoldering two-key PV

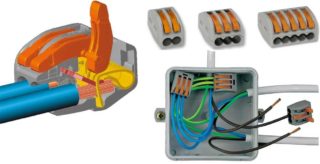

When performing the scheme of a two-key pass-through switch, it is necessary to think over the method of fixing the wires. Popular technologies include twisting followed by soldering or welding of the ends.

A popular method of fastening is to fasten the wiring elements with spring clips on the contacts. For the strength of the electrical connection and quick assembly, it is advisable to use:

- WAGO terminals. Reusable clamping clips that can be removed during line repairs.

- Clamps Werkel. They are located at the ends of the contacts. By pressing a button, a hole opens on the terminal. An uninsulated end of the wire is inserted into it.

The phase end is thrown onto the first contact. A jumper is made between him and the first.

Major mistakes when setting switches

In the process of connecting two-key switch models, beginners make several mistakes:

- Small wire length. There should be 15-20 cm in the junction box for twisting.

- The insulation remains on the cable. From the upper part, the coating is removed almost completely, from the veins - by 3-5 cm.This is necessary for the convenience of implementing the circuit and for high-quality twisting.

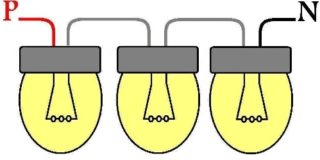

- The bulbs are connected in series. Parallel connection ensures the normal operation of the line when one element burns out.

- At DPV, neutral is turned on. It is necessary to take a phase in order to prevent a line closure, leading to breakdowns of household appliances.

- The junction box and socket boxes are mounted on gypsum without the cable ends being wound. It is not safe to touch exposed wires.

The socket boxes should be masked with decorative panels.

Two-key switch models are stand-alone devices in one housing. The convenience of their operation lies in the control of light from different areas of the room. For correct installation, you will need to select the wire cross-section and purchase it with a margin of length.