Automatic gates are convenient due to opening by touching the remote control button from a certain distance. The structure is installed at the entrance to the garage, to the courtyard of a residential building or suburban area. If you have the skills, you can independently make a leaf, supports and an electric drive for the gate.

- Features of electric swing gates

- Varieties of electric drives for gates

- The main units of gates with automation

- Installation materials, tools

- How to choose and install an electric drive

- Self-assembly of automation

- Characteristics of permissible nodes

- Control type

- Basis for the mechanical part of the drive

- How the device works

- Bicycle sprocket assembly option

- Homemade actuator for automatic gates

- Manufacturing nuances

- Arrangement of automatic swing gates with your own hands

- Drafting a project

- Fabrication of canvas

- Welding a reinforcing frame

- The need for a frame

- Construction of supports

- Gate installation

- Installing the drive

Features of electric swing gates

The automatic type of swing gates differs from the standard ones in the presence of an electric drive. The two flaps can be opened inward and outward. When making products with your own hands, you need to consider the advantages and disadvantages. The advantages of swing structures include:

- the possibility of arrangement even with a limited budget;

- popularity - all automation units are on sale;

- unimpeded passage of vehicles if space is available;

- execution of sashes from any materials;

- ease of self-assembly of the canvas.

The disadvantages of automatic gates are associated with lengthy work on digging in and concreting the pillars, the need for a large space for opening the leaves. For normal operation of the electric drive, two engines are required, which is associated with significant financial costs.

Varieties of electric drives for gates

The drive mechanism of the structure is a metal "hand" that directs the shutters to the desired position on command from the remote control. For self-installation, you can choose a drive of two types:

- Linear - the nodes are compactly located in one housing. The solution is suitable for entry groups of townhouses, private houses, summer cottages, cottages outside the city.

- Lever - the electric drive is installed on the garage entrance, massive, easy to operate and reliable.

- Hydraulic - used for areas with high throughput, works on the principle of pumping oil pressure.

There is no significant difference between the types of electric drives, but for selection it will be necessary to take into account the total weight of the canvas and its dimensions, the distance from the side support to the center of the loop.

Before mounting the drive, the sashes are adjusted.

The main units of gates with automation

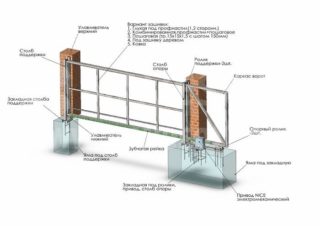

The gates, equipped with an automatic mechanism, open quickly, eliminating unnecessary user actions. The design includes:

- rigid metal frame;

- electric drive;

- support posts, or racks;

- metal gate valve;

- decorative cladding;

- large loops.

To further strengthen the frame and increase its wind resistance, stiffeners are installed inside.

Installation materials, tools

Independent production and installation of automatic swing gates is made from the following materials:

- professional pipes with a section of 60x30 mm and 40x30 mm;

- channel or profile pipe with a cross section of 10x10 cm;

- decorative sheathing - corrugated board, wood, sandwich panels;

- brick for racks;

- reinforcement 14 mm in diameter;

- electrodes for welding parts of a structure;

- crushed stone, cement and sand for mortar preparation;

- anti-corrosion primer, alkyd enamel and solvent;

- insulating PVC tubes;

- an electric wire with three cores for powering the automation.

To complete the work, you will also need a ruler, a level, a screwdriver or a riveter, a grinder, a welding machine, and a special brush for metal surfaces. For digging trenches under the posts - a shovel, to protect the electrical part - an RCD. It is better to paint the product with a paint brush. An indicator screwdriver can be used to check the voltage.

How to choose and install an electric drive

The standard swing product becomes automatic at the last stage of installation. To make the right choice of a drive, you need to consider:

- Distance from the inner edge of the support to the hinge. If it is up to 15 cm, a linear electric drive without handles is suitable for the gate. For a distance greater than 15 cm, a linkage mechanism is advisable.

- Automation must be adjusted. The smoothness of movement of both leaves is checked. If force is applied during opening, it is removed.

- The canvas should not be skewed. Otherwise, the automation will last up to 12 months.

Before putting the door into operation, lubricate all exposed parts.

Self-assembly of automation

Do-it-yourself sliding gate automatics are mainly made from car windows. The part will need to be finalized for a quiet ride. The disadvantage of the device is the limitation of tractive effort. During the assembly process, you need to consider:

- For the drive to the gate, power windows with a movable element in the form of a toothed rack or powered by a wheel with teeth are suitable.

- The electric drive is placed on a metal platform rigidly fixed to a post or fence.

- The rail moves towards the web, parallel to its plane.

Window regulators are being finalized as follows:

- An elongated metal rod is placed on the rail, and a knee lever on the wheel.

- A pull rod with a drive or two parts of the knee lever with the curtain are connected according to the principle of door closers.

- To prevent backlash and quality of movement, two folded metal plates are installed in the connection section. The distance between them corresponds to the width.

- The entrance to the resulting hole is checked. The second hinge plate smoothly falls into it.

- Fastening elements in the form of a finger using a bolt or self-locking nut.

- Selection of the position of the actuator. Swing gates are set open and then slowly closed.

Upon completion of installation, the automatic mechanism is placed in a protective casing.

Characteristics of permissible nodes

When installing automation suitable for sliding gates and doing all the work with your own hands, you need to take into account the technological aspects of the product.

Control type

The standard control device can be replaced with the ACSTM 114R. The two-channel wireless module opens and closes the flaps according to the principle of “code hops”. The machine's signaling panel can be used as a control mechanism. It will prevent overloading of the structure and eliminate the risk of foreign objects getting between the sashes.

Basis for the mechanical part of the drive

The manufacture of an electric drive for sliding gates is carried out on the basis of a DC reducer / motor powered from 12-24 V. Such a scheme functions smoothly in bad weather and in case of blockages. Suitable as an electric motor:

- VAZ-2110 car wiper with high output torque;

- MAZ wiper - the element from the truck is designed for 24 V and operates at high power;

- reducer for the leaf from the elevator door;

- the engine from the VAZ radiator cooling fan - operates by means of the i-80 worm gearbox.

The actuator requires a pair of pins 1 m long and 16-20 mm in diameter.

Use inexpensive motors without disassembly - the worm gear is already in a special casing.

How the device works

The electric gate drive works by sending an impulse from the gear of the gear motor shaft to the driven gears of the ends of the studs. For this, torque and hypoid transmission are involved.

At the moment of rotation in the opposite direction, the gears on the hairpin are motionless. Only the nut connected to one end of the rod moves. The second end is connected to the sliding structure canvas. The screw, while rotating, moves the nut along the slide guide. This element pushes the rod on the gate.

The second part of the drive mirrors the functionality of the first. The screws rotate towards each other, and the nuts move apart depending on the direction of rotation. The rods are used to move the flaps behind the nuts.

Factory-made brass nuts feature a wear-resistant thread. For strength, a steel casing is put on over the element, the rod is attached to the hinges. Angular contact bearings provide optimal load distribution. The system is installed above the channel over the gate, which is connected to the support posts.

Bicycle sprocket assembly option

The driven gear is activated by a geared motor. The gear pulls the chain along the profile guide tube. Carriages with traction joints move along it.

The use of two bicycle sprockets with a hub and a bicycle chain or steel cable makes the adjustment process easier. In terms of cost, this system is cheaper, but revision requires the use of drilling or turning equipment. Not every home craftsman has such machines.

Work with ready-made nodes.

Homemade actuator for automatic gates

An actuator is a device with a ready-made system of a DC motor, a gearbox, a rod with a trapezoidal thread, a ball screw nut. When moving, the rod does not rotate around the axis, has a stroke length of 50 mm to 50 cm.The motor delivers a voltage of 12 or 24 V.

The finished unit in the assembly is designed to operate from a network of 110, 220 and 230 V, withstands loads from 200 to 10 thousand Newtons, is compatible with limit switches.

Manufacturing nuances

Automatic shutters work remotely, but the quality of the structure's functioning depends on the type of electric drive. When self-manufacturing, you need to take into account:

- complete set of the finished automation system - photocells and a control unit for opening the sash in 15 seconds;

- there should be no obstacles in front of the opening - they will cause jamming;

- for a homemade drive, you can take a satellite dish mechanism powered by 36 V;

- the optimal range of the remote control is at least 50 m. The remote control requires two remote controls and a current relay;

- the type of decorative trim, its weight, and the intensity of opening determine the category of the drive.

For normal operation of the structure in winter, it is better to make an electric drive with a power reserve.

Arrangement of automatic swing gates with your own hands

The independent creation of swing gates equipped with automation occurs in stages.

Drafting a project

The drawing, which shows the dimensions, appearance and features of the automation, is drawn up on paper by hand or in a special program.

Fabrication of canvas

According to the size of the product on the main material, markings are made taking into account the dimensions of the flaps and the gap between them. The material can be profiled sheet or steel. For stiffening ribs, you will need a professional pipe. The elements are cut out on a machine and connected with a welding machine.

Welding a reinforcing frame

Rectangular frames are connected with rigid jumpers and sheathed. The assembly is carried out on a flat surface, the geometry of the sash is carefully checked.

The need for a frame

No construction is needed at the entrance - the sashes are fixed on the racks with canopies. If there is a frame, its parameters are calculated, the diagonality and parallelism of the lines are maintained.

Construction of supports

After measuring the opening, marks are installed and holes are dug along them, the bottom of which is covered with rubble. The columns are leveled and filled with concrete.

Gate installation

For fastening the canvas, canopies and balls are used. The doors are placed in the frame contour, the evenness of the arrangement is checked and welded to the canopies. Frameless products are attached with clamps and reinforced by welding.

Installing the drive

The electric drive is installed on the gate upon completion of the door leaf installation process. After that, the power supply option is selected and the connection is carried out according to the scheme. Equipment with wires is hidden in a mounting box. At the final stage, the system is checked.

Automatic gates are controlled remotely, which increases the comfort of living on the site. If you have the knowledge and skills to work with electrical appliances, you can not buy a drive for the sash, but make it yourself.

/