Difficult temperature conditions in the room impose conditions on all devices and electrical networks. High temperatures and high humidity levels increase the risk of wire and cable breakage. For work in saunas, baths, swimming pools, special-purpose heat-resistant conductors are used, including the RKGM.

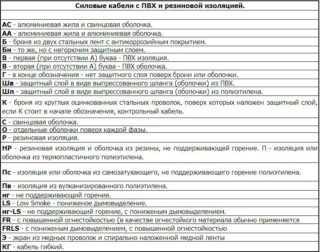

Abbreviation and Specifications

Heat-resistant cable is a type of cable product that has a high degree of resistance to negative factors. A feature of this type of product is the presence of additional insulation made of non-combustible material. They are single-wire and multi-wire. The former are more rigid, inflexible. They should be laid with the least number of fasteners. Reduced resistance when operating at low frequencies. Multi-strand suitable for installations with a lot of twists and turns. A variety of such cables with a multi-wire structure is the RKGM conductor.

Heat-resistant wire RKGM is designed for networks with voltages up to 660 V. The main characteristics can be found in the description of the name. Marking is deciphered in the traditional way for wires:

- The material of the conductors is copper, since there is no letter A at the beginning of the marking.

- RK - silicone rubber insulation.

- G - flexible.

- M - fiberglass outer braid. Additionally impregnated with heat-resistant varnish and enamel.

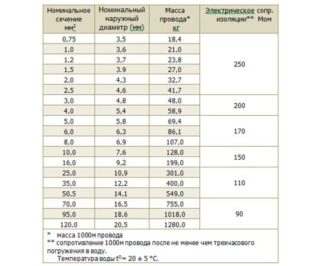

The letter code is followed by a number. It shows how much cross-sectional area a given conductor has. Depending on this indicator, the cable can pass a current of varying magnitude.

The wire is unarmored. Technical characteristics of RCGM:

- The operating voltage is 180, 220, 380 and 660 volts.

- 4 class of flexibility.

- Stranded conductor.

- Section - from 0.75 sq. Mm. up to 120 sq. mm.

- The minimum bending radius is 2 diameters.

- Works at 100% humidity. In this case, the temperature should not be higher than 35 ° C.

- Working frequency up to 400 Hz.

- It can operate at pressures from 130 Pa (1 mm Hg) to 294 kPa.

- Operating temperature range from -60 ° С to + 180 ° С.

- The minimum gasket temperature is 15 ° C.

- It works for 8 years if the operating conditions are observed.

- Resistant to combustion.

- Possibility of installation in conditions of formation of fungi, mold.

- Vibration resistance.

Available in different diameters and weights. Sold in bays 100 and 200 meters long.

During the installation process, multiple bending of the conductor (about 15 times) is permissible without damaging it.

What the RCGM consists of

Mandatory elements of cable RKGM are:

- Insulation. This layer is located above the vein. Made of silicone rubber. The thickness of the insulating layer depends on the operating voltage for which the conductor is designed. Increases with increasing load.

- Outer shell. It is a braid made of fiberglass threads with special impregnation with KO-921 varnish. Gives increased strength and flexibility to the product.

The use of insulation and outer sheath makes the RKGM cable reliable and allows it to be used in difficult climatic conditions.

Application area

In everyday life and industry, machines operate on the basis of electromagnetic induction. During switching, the contact points get very hot, which can cause a regular wire to collapse.RKGM cables are designed in such a way that destruction does not occur even at large temperature differences.

Since the wire is heat resistant, it is usually used in places with high temperatures. Due to its characteristics, the conductor is used in the following conditions:

- Installation of electrical circuits in rooms and outdoors in temperate climates.

- Making windings in powerful equipment.

- Use in the chemical industry.

- Housing construction. Creation of a lighting group, connection of household appliances and sockets in rooms with high temperatures and humidity.

- Installation in areas with a high risk of mold and mildew formation.

In everyday life, RKGM is used in baths, saunas, rooms with high temperatures. It is actively used in bathrooms and basements. With the help of a heat-resistant RKGM 2.5 wire, you can also connect electric stoves, ovens and other powerful equipment in the kitchen or bathroom.

The conductor is not suitable for work in negative temperatures. The sheath has low resistance to cold conditions, therefore other cable products should be selected.

Wire manufacturers RKGM

Many factories of electromechanical products are engaged in the production of RKGM cable. The highest quality products in accordance with GOST and widespread products are produced by the following enterprises:

- Uralkabel.

- Kamkabel.

- Rybinskkabel.

Manufacturers are obliged to produce the cable in accordance with the technical specifications TU16.K80-09-90.

Varieties of conductors

RKGM cable is produced for different operating frequencies, with different cross-sections and, accordingly, different parameters. The main types of conductor:

- RKGM-0.5. 0.5 sq. Mm. Is the cross-section of the wire. Works at a frequency of up to 400 Hz.

- RKGM-16. Section 16 sq. Mm. Application conditions - from -70 ° С to + 190 ° С with a frequency of up to 400 Hz. Cannot be used in hostile environment.

- RKGM-50. The cross section is 50 sq. Mm., The main use is electrical units with a pressure from 1.4 kPa to 295 kPa. Temperature range from + 60 ° С to + 180 ° С.

- RKGM-95. Designed for use only at 660V and 400Hz. Average temperature of use is 25-35 ° С.

- RKGM-150. The largest product used at a voltage of 380-660 V and frequencies of 100-400 Hz. Can be installed at temperatures from + 15 ° C to + 30 ° C. Working pressure from 1 kPa to 300 kPa.

The flexibility class and properties are also determined by the number of conductors.

Installation recommendations

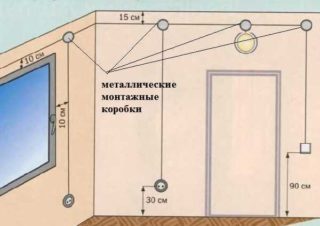

In order for the conductor to function efficiently and reliably during the stated period, the operating requirements must be observed. When laying, take into account the following rules:

- The cable line can only be turned at right angles.

- Vertical and horizontal routing possible.

- It is undesirable to allow crossing of cables.

- The optimum distance between the cable and the heating pipe is 3 cm or more.

- The distance to windows or doors is at least 10 cm.

Installation is possible both open and hidden. With an open installation, wires can fit into channels, corrugated tubes, rigid frame pipes, braided metal sleeves. Closed wiring is more complex. The master is obliged to comply with all the requirements and recommendations that are regulated by the technical conditions. Air routing of conductors is also possible. It is suitable for suspended ceilings and under flooring.

Before installation, the wires must be checked. There should be no kinks, insulation breakdowns, bare areas. The indicator tests the cables before and after installation.