Lighting devices are used to create backlighting in homes, industrial buildings, outdoors, in museums and other areas. One of these products for creating artificial light is the DRL lamp. This is a device that belongs to the category of mercury discharge lamps. DRL has a different way of working from other light sources, which should be figured out in advance before buying or when choosing analogs.

What is a DRL lamp

First of all, it is worth understanding the name, because it is by it that the master determines the characteristics and working conditions. The abbreviation DRL can be deciphered as follows:

- D - type of ignition. The source ignites under the influence of an electric arc that forms when voltage is applied.

- R - mercury.

- L - the conversion of ultraviolet light into visible light is carried out using a phosphor.

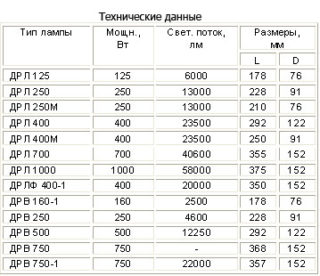

Also in the marking after the letters you can see a three-digit numeric code. It shows the power for which the lamp is designed. On sale you can find devices with a power of 150 W, 200 W, 250 W, 400 W and other load values. In everyday life, 250 W and 400 W bulbs are usually used.

Design features and principle of operation

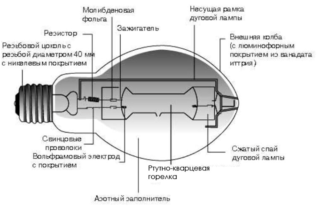

The DRL lamp has a standard design for gas-discharge lamps. It consists of three parts - a glass bulb, a base and a burner. The burner contains electrodes and a limiting resistor. The flask is evacuated and then filled with nitrogen. A phosphor is applied on the inner surface. The burner contains a mixture of inert gases and mercury. Bulb caps are different, the standard is E14 and E27.

The DRL light bulb works in the same way as a gas-discharge one. When voltage is applied to live parts, a glow discharge occurs. As a result, electrons and ions accumulate and the inside of the tube heats up. The mercury evaporates, and the glow discharge becomes an arc. As the amount of mercury vapor increases, the brightness of the glow increases. The resulting ultraviolet light hits the phosphor. When passing through it, it is converted into visible radiation.

If the operating conditions are observed, the time for turning on the light bulb and reaching the declared parameters is about 4 minutes. This time decreases with increasing temperature.

DRL lamp types

DRL lamps have several modifications that have different technical characteristics and operating conditions.

- Classic DRL lamp. Standard modification. The disadvantages of the model include high heating during operation, sensitivity to voltage changes, and a long time to reach optimal performance. The most common ones are the DRL 250 lamp and the DRL 400. The luminous flux of the DRL 250 allows you to use the device in home lighting.

- DRV or DRVED - arc mercury tungsten (erythemal tungsten) lamp. The product starts without the use of a choke and has improved light emission.

- DRLF - in contrast to a standard lamp, it has improved characteristics due to the coating of the bulb with a reflective material.

All listed types can replace each other.

Specifications

Also important indicators are:

- Light flow.This value determines how many bulbs are needed to create the required level of illumination per unit area. The DRL 400 has a luminous flux of 18,000 lm.

- Estimated time of operation. Shows how many hours the light bulb can work under the stated conditions.

- Base / plinth. Sets the parameters for a chandelier or other lamp.

- Dimensions.

- Supply voltage.

All these parameters, as well as the operating conditions, can be found in the documentation for the lamp.

Application area

DRL lighting devices are actively used as a source of artificial light in external and internal lighting: to illuminate roadways, highways, parks and squares, as well as industrial premises and industrial workshops with a capacity of several megawatts.

DRV products are used in the same facilities as DRL, as well as in lighting agricultural enterprises that grow various crops in insulated soil. These can be greenhouses, greenhouses, orchards.

Lamp connection

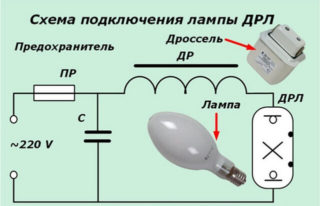

The DRV modification does not need a choke for connection. The light bulb can be directly connected to the mains. The throttle lamp connection diagram requires a ballast. This device provides regulation of the current strength within the specified limits. With the help of a choke, you can exclude burnout of the light source and create a mode for starting it. The choke also adjusts the operation of the device by stabilizing the operating voltage supplied to the contacts.

There are two types of chokes - independent and built-in. They are installed in various designs of luminaires and depend on the place of installation of the ballast (ballast).

The following parameters influence the choice of the ballast model:

- the electric power of the light bulb;

- operating current and voltage;

- winding temperature;

- the highest permissible heating;

- greatest power loss;

- Power factor.

The most common breakdown in gas-discharge drl lamps is associated precisely with control gear malfunctions. The device will not light up during operation. For this reason, it is important to be able to test the choke for performance. This can be done with a multimeter, which will check the integrity of the windings and the presence of an interturn short circuit.

Another way to check is with an incandescent lamp of the same wattage connected in series in the circuit. If the product is in good working order, the lamp will light up at half incandescence or will blink. In the absence of light, one can judge the damage to the winding. Too bright light indicates the presence of a turn-to-turn short circuit.

Pros and cons

DRL lamps are quite popular light sources. This is due to their positive qualities, which include:

- long service life;

- compactness;

- standard plinths;

- good luminous flux;

- reduced power consumption.

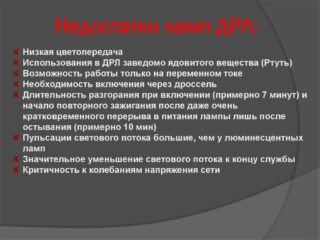

- Susceptibility to voltage changes.

- The presence of pulsations that are harmful to human health.

- Long ignition time.

- Presence of harmful ultraviolet light.

- Lamp modifications have lower efficiency and service life.

- The presence of harmful components in the composition.

- Fragility. The glass flask is easy to break, so you need to work with the device carefully.

- Difficulty of disposal. Mercury and other harmful substances contained in the appliance mean that the light bulb must not be disposed of with household waste. It is disposed of at special collection points.

Despite all the advantages of such light sources, most electricity consumers are switching to LED counterparts. They are safer, have a longer service life, and have improved performance. The e40 LED lamp, an analogue of DRL 400, has practically supplanted the gas-discharge product.

In 2014, the Russian Federation signed the Minamata Convention. According to this document, starting from 2020, the production, use, export and import of mercury products should be stopped.Gas-discharge devices fall under the ban, therefore it is already recommended to think about replacing the DRL 400 with LED lamps with improved characteristics and a high degree of environmental friendliness. This applies to both home and industrial and outdoor lighting fixtures.

As an evil, they produced high-pressure mercury lamps of the DRL type, as a lamp designed exclusively for operation only on alternating current of industrial frequency. However, practical tests of all these lamps on a purely direct current allowed me not only to eliminate their harmful flickering of the luminous flux, but also to extend their physical useful life by a substantial percentage !!! The fact is that when an AC arc discharge burns in them, all the evaporated active material of the emitter from their oxide self-heating cathodes, with a periodic change in the polarity of the AC in the arc discharge in the lamp, is thrown from side to side depending on the direction of the current in the arc discharge into lamp, and in a suspended state deposits on the entire inner surface of the quartz bulb of the discharge tube of the lamp, greatly blackening it !!! But if an arc of a continuous purely constant unidirectional current is ignited in the quartz discharge tube of a DRL lamp, the picture of lamp wear changes dramatically in a favorable direction. Instead of weighing the evaporated active material of the emitter of the lamp oxide cathodes with its subsequent gradual deposition on the walls of the quartz discharge tube of the lamp with their blackening, in a purely direct current arc discharge, its one-sided transfer from the anode with its deposition onto the cathode with a minimum of its ejection onto the walls of the quartz discharge tube lamps with their blackening. And the quartz bulb of the discharge tube of the lamp along its entire linear length practically remains transparent for most of its service life, only slightly blackening against its cathode, thereby preserving its light transmission. And by this, the operation on a purely direct current of high-pressure mercury lamps of the DRL type significantly extends their useful life, while maintaining their previous luminous flux without such a brutal decline. When operating on a purely constant current, the DRL lamp behaves like a powerful zener diode, like an assembly of LEDs connected in series, and instead of the ballast choke intended for it, it requires similar circuit solutions to stabilize its operating current with power supply of LED assemblies of LED lamps, only for higher power and higher operating current lamps. So why then did the electric lamp factories. Did not develop and produce high-pressure mercury lamps of the DRL type specially designed for their operation only on a purely direct current with only one self-heating oxide cathode in the quartz discharge tube of the lamp and one ignition anode opposite it and a working anode in the form of a solid a pointed tungsten rod without any oxide coating instead of a second self-heating oxide cathode on the opposite side of the quartz discharge tube of the lamp? Why did engineers then place such an emphasis on high and ultra-high pressure mercury lamps of exactly alternating current, if their technical characteristics were always worse, and the useful life due to the intense blackening of their quartz bulb during their operation is much less than that of these lamps? pure dc? They really liked to produce an excessive amount of mercury waste requiring special processing, knowingly reducing the useful life of their high and ultra-high pressure mercury lamps !!! Alexei.

Generally, when operating on DC, the cathodes quickly become too thin.