Installation wire PV 1 is used for laying under layers of building mixtures, for example, plaster, in cable trays, building voids and pipes. Due to the large number of advantageous features, it is actively used not only in industry, but also in everyday life.

Explanation of the name and nomenclature of wires PV1

The main advantage of the cable is the combination of an acceptable cost with good mechanical and electrical characteristics. It is necessary to understand the decoding of the name and the existing types of PV1 wires produced and used in Russia.

The abbreviation PV-1 stands for the following:

- The letter "P" means that we are talking about a wire. In addition to wires, the letter "Ш" or "К" can be used, cords and cables, respectively.

- The letter "B" indicates the type of insulation material used. In a specific case, it is insulation made of polyvinyl chloride. Due to its stable physicochemical properties, this insulation is often used as a dielectric.

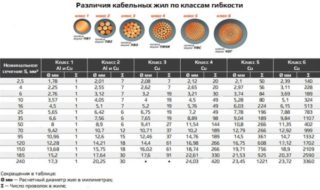

- The number "1" indicates the flexibility class. The lower the number, the greater the bending radius the wire, cable, cord, etc. can be subjected to.

There are installation and assembly wires. The former include modifications that are designed for long-term use in one position, the latter can be rewound many times. All modifications of the PRV wire, with the exception of PV-3, refer to installation.

Special attention should be paid to the types of PV-1, which are produced by the domestic industry. In accordance with GOST No. 6323-79, all wires of this brand should have the following dependence of the cross section on the mass:

| Nominal cross-section and number of cores, mm.kv | Weight of 1 km of cable, kg | Maximum outer diameter, mm |

| 120 | 1060 | 17,5 |

| 95 | 956 | 17,00 |

| 70 | 691 | 15,00 |

| 50 | 511 | 13,00 |

| 35 | 362 | 11,00 |

| 25 | 260 | 9,80 |

| 16 | 172 | 8,00 |

| 10 | 107 | 6,40 |

| 8,0 | 80,2 | — |

| 6,0 | 65 | 4,90 |

| 5,0 | 54,8 | — |

| 4,0 | 45 | 4,40 |

| 3,0 | 37,7 | — |

| 2,5 | 30 | 3,90 |

| 2,0 | 26,2 | — |

| 1,5 | 19 | 3,30 |

| 1,0 | 13 | 2,80 |

| 0,75 | 10 | 2,60 |

| 0,5 | 8 | 2,40 |

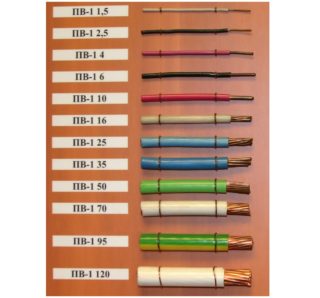

All brands of wires PV-1 are single-core.

Specifications

Mechanical

- One of the main features of all brands of wires is the ability to bend. PV-1 cannot be called flexible. The bending radius is no more than 10 outer diameters of this wire.

- The operating temperature range ranges from -50 to +70 degrees Celsius.

- A significant advantage of this brand is moisture resistance. The test results showed that at a temperature of +30 degrees, the wire does not lose its performance even at a relative humidity of 100%.

- It has good resistance to acoustic, vibration, mechanical, thermal, chemical and other influences.

Another advantage of the modification is that it does not spread combustion. Thanks to this feature, the wire was taken as the basis for the high-voltage PVV-1, which is actively used in the automotive industry.

Electrical

It is the electrical characteristics that are most often fundamental. In this case, PV-1 shows itself from the best side.

- The electrical design is intended for use in alternating current electrical networks with a voltage of up to 450 V and a frequency of no more than 400 Hz. When it comes to DC networks, the voltage should be no more than 1 kV.

- The resistance force primarily depends on the cross-section of the wire. For example, 0.5 mm.kv resistance is not more than 0.015 Mohm, otherwise there will be malfunctions.

- The peculiarity of PV-1 is stable parameters.Even during use, the electrical resistance does not differ from the nominal parameters by more than 120%.

All studies are carried out on a wire 1 km long and at an operating temperature in the range of + 70-90 degrees.

Design features

PV-1 is a single-core wire. Can be used to connect only one piece of equipment. An electrical part is made of high-quality copper, which is pre-tinned.

The PV has an extremely simple design. Includes the following elements:

- An insulating material that covers the surface of the wire. Consists of polyvinyl chloride. It is color coded by the customer if it is not a grounding cable.

- Copper conductor. Its structure depends on the cross-section of the cable.

In the range from 0.5 to 10 mm2, the conductors are cast, more than multi-wire can be used.

Scope of application and service life

There are no strict restrictions on the application. It is actively used for switching stationary electrical installations and lighting systems. Also, the electrical design is used on machines in which it is required to reliably connect several mechanisms or work units.

A wide range of applications is due to the following advantages of PV-1:

- PV-1 and PV-3 have minimal linear expansion.

- The assembly wire is characterized by its high strength, due to which it withstands numerous and perceptible mechanical stresses.

- The insulation is made of polyvinyl chloride, which is self-extinguishing.

- On the surface and under the shell, the likelihood of the development of pathogenic microflora is excluded, which will adversely affect the performance, the quality of data transmission and the service life.

Wires can be placed inside plastic and metal pipes, cable trays, and inside equipment. Yellow-green modifications are used to implement the grounding system.

The service life of the installation wires, subject to all the rules of use, reaches 15 years or more. In comparison with a large number of other modifications, these are high rates.