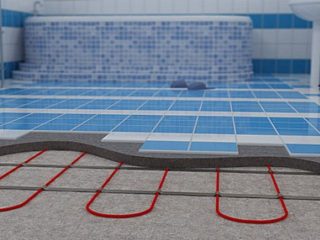

Ceramic tiles are a practical and aesthetic option for floor finishing. Its disadvantage is its cold surface. In the cold season, it is uncomfortable to walk on it, especially barefoot. The solution to the problem will be laying an electric underfloor heating under the tiles. It is sold in the form of heating cables and mats. The electric wire will be cheaper, but it is worth considering the increase in the floor level due to the screed and the complexity of installation. Heating mats are easier to install, but more expensive.

- Preparation for laying a warm electric floor

- Underfloor heating cable type

- Resistive

- Self-adjusting

- Calculation of the amount of cable

- Mesh heating mats

- Laying technology

- Surface preparation

- Scheme creation and calculation

- Installing the temperature sensor

- Underfloor heating cable installation

- Laying heating mats

- Filling the screed

Preparation for laying a warm electric floor

Regardless of the selected heating system, you will have to prepare the floor for installation. The coating is removed first. After examining the old screed, its condition is found out. In some cases, dismantling is advisable. This will gain a few centimeters of room height. Before laying, materials for hydro and thermal insulation are purchased.

Underfloor heating cable type

The heating cable under the screed can be used as the main or additional element for heating the room. There are two main types of devices:

- resistive;

- self-regulating.

To determine the choice, you should examine the advantages and disadvantages of each element.

Resistive

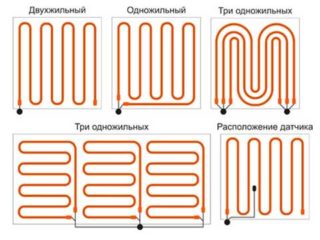

A feature of the heating wire is the same temperature in any area. Heat is generated due to the high resistance of the material. Resistive elements are of two types.

Single core the wire has 1 conductive core, 2 layers of insulation and a braided shield. For connection, it is required to bring the ends together at one point, which complicates installation. Pros:

- economical energy consumption;

- the ability to generate heat;

- affordable cost.

Two-core the heating element consists of two sheathed cores. The metal mesh prevents the propagation of electromagnetic pulses. Pros:

- ease of installation, circuit closure is provided by a special coupling at the end of the wire;

- you can create a diagram of the desired configuration;

- high degree of shielding.

A common disadvantage of resistive-type products is the inability to adjust temperatures in individual segments. In the event of a breakdown at any point, the system fails.

Self-adjusting

The cable structure includes: two conductive cores, a semiconductor matrix, a metal braid and an insulating sheath. The degree of heating of the wire depends on the ambient temperature. Product advantages:

- overheating in certain areas is excluded;

- low power consumption;

- long service life.

The main disadvantage of the element is its high cost.

Calculation of the amount of cable

For efficient operation, the warm floor should cover about 70% of the area of the room. The material does not fit over the entire surface. Places where heavy furniture is installed are excluded. It is necessary to calculate the value of the covered area. When calculating the cable, the average power indicator of the heating system is taken. It depends on the type of premises and the purpose of the system:

- main heating - 180 W / m2;

- auxiliary - 110-140 W / m2.

In a well-insulated room, a system of lower power is installed; on the balcony and the first floor, the parameter is taken with a margin of 20%. The total cable power is calculated by multiplying the average by the usable area.

Mesh heating mats

A wire mat is a construction made of a resistive cable fixed to a polymer mesh. The wire is laid in coils and is securely fastened. Systems of various power from 120 to 200 W / m2 are on sale. The advantage of the mats is the simple installation technology.

Laying technology

Installation of heating cables of both types and mats is carried out using a similar technology and has a general preparatory stage. System design nuances affect electrical connections.

Surface preparation

The first step in surface preparation is leveling. There should be no drops in level, cracks and protrusions. If necessary, fill in a new screed. The main work continues after it dries. Thorough cleaning is carried out before laying the warm floor. The surface is cleaned of dust and debris, primed. In rooms with high humidity (bathroom, toilet), the floor is waterproofed with bitumen or liquid glass.

Thermal insulation is performed to reduce heating costs. The rooms on the ground floor are insulated with foam, in the rest of the rooms it is enough to lay foil-clad foam. In places of indentation from the walls, a damper tape is placed. It compensates for the expansion of the concrete when heated.

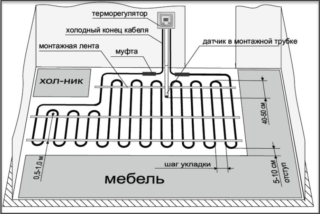

Scheme creation and calculation

Before the start of installation work, a laying scheme is drawn up. It shows the placement of the cable (mats), the place where the thermostat is connected. The scheme takes into account the recommended distance from the walls by 50-100 mm. Areas occupied by furniture without legs, on which heating elements cannot be placed, are marked.

By calculating the specific thermal power required for the room, you can choose the length of the cable. Typically, products are sold in coils of a certain size with end sleeves for connection. When choosing an electric underfloor heating, the main parameter is power. The length of the wire is calculated by dividing the total power by the linear power indicated in the characteristics. The step of the turn is determined by the formula: h = Sx100 / Lwhere:h - laying step, S - effective area, L - length of cable.

Connecting a warm floor gives an additional load of several kilowatts. The wiring should be checked by an electrician. This is a guarantee to prevent fire from short circuits.

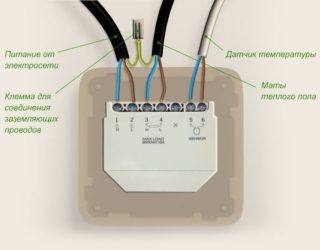

Installing the temperature sensor

The underfloor heating set is equipped with a thermostat and a temperature sensor. The thermostat can be mechanical and electronic, with its help the temperature regime is set. The sensor measures the temperature of the floor heating and is connected to the controller by a wire. A groove is made for the devices in the wall and a hole is made at a height of 80-100 cm. The sensor is placed in a corrugated pipe. It protects the device and allows it to be replaced. The thermal sensor is laid between the cable turns, the distance from the wall is 50 cm.

Underfloor heating cable installation

Mounting tapes are fixed on the foil surface of the insulation. These are flexible metal elements with ready-made fasteners. The second option is to use fiberglass mesh. The canvas is laid out on the surface, the cable is attached to it with plastic clamps. The calculated distance is observed between the turns, their intersection is not allowed.

The system resistance is checked before installation. It must correspond to the parameters of the passport. Allowable discrepancy is 10%. A single-core cable is connected to the thermostat with two ends, and a two-core cable - with one, a sleeve is installed on the second. The installation of an electric underfloor heating under the tile ends with a resistance test.

Laying heating mats

Electric mats are laid out on the floor according to the diagram.For turns, the mesh is cut without damaging the wires. After installation, the commutation is checked. The connection to the thermostat is carried out according to the color marking of the wires. The procedure is regulated by the manufacturer's instructions.

Filling the screed

A 5 cm thick concrete screed is poured over the heating cable. For mats, tile adhesive can be used, but the base must be at least 3 cm. The solution is carefully distributed over the surface. The next stage begins after the screed has set.

Before laying tiles on a warm electric floor, they are soaked for several hours. The cladding is mounted on a special heat-resistant adhesive. The mixture is applied to the substrate with a notched trowel. The tiles are leveled. The first heating of the electric floor under the tiles is allowed after the screed has completely dried, after 4 weeks.