Earth plays an important role in electrical wiring. It ensures the safety of a person against electric shock in the event of a short circuit and other emergencies. Grounding must be in accordance with the modern requirements of the PUE (rules for electrical installations). When carrying out repairs, it may be necessary to disconnect the working ground bus, so you have to install a portable ground. In order to do everything correctly and safely, you need to understand in what sequence it is necessary to install portable grounding. To do this, use the recommendations and installation rules.

What is portable grounding

All types of grounding have the same purpose and belong to protective equipment. The portable type is used on temporary objects in which it is impossible to indicate a permanent connection to the ground.

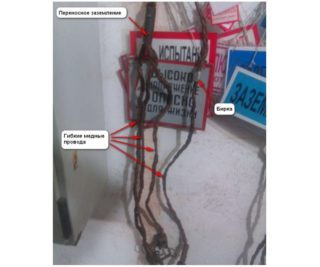

The temporary grounding kit includes flexible wires with clips at the ends of the permanent fixation. Usually the conductors are connected in three lines when connected to three-phase installations. Lugs must have insulated rods, since work can be carried out at voltages above 1000 V. This ensures safety in the event that the bus is energized. There are also models for single phase equipment. They have one conductor with a clamp at the end.

The use of portable grounding is dangerous without protective equipment in the form of circuit breakers and fuses. This is due to the fact that a short circuit can result in a fire in the power cable.

Portable grounding equipment performs another important task - protection against induced voltages. When the installation is de-energized, induced currents from adjacent conductors can form on the cable. It is the earth that prevents the appearance of such currents, therefore, the installation of grounding for electrical equipment is mandatory.

equipment requirements

Working with any electrical equipment requires safety precautions. The main requirements are:

- The integrity of the cable along its entire length. It should be without kinks, cracks, violations of the structure itself, turns and breaks of veins. Otherwise, such a wire should not be used.

- Insulated cables must not be used. It is difficult to control the integrity of the conductor under the containment.

- The cable must have the same cross-section along its entire length. The choice of area depends on the load to which it is connected. The calculation can be made according to special tables. If the cross-section is insufficient, the device will not withstand the load and, accordingly, will not protect the person.

- The length should be selected so that the grounding bar and equipment can be connected without pulling on the wire. It should not be suspended unless the earthing points are high. This applies to power lines.

- The conductor is selected to withstand the appropriate climatic conditions. It must not heat up and must withstand the dynamic breaking load.

- The insulating hoses must be of such length that the clamps can be applied without the operator being approached or touched.

- It is recommended to use screw-tightened clamps to ensure a secure fit. The material must be resistant to heat and form scale at the junction. When tightening it, contact should not deteriorate.

- The clamp and the conductor are connected by welding or crimping. It is also possible to establish a connection with a nut with a soldered contact point. It is forbidden to use only overlay and soldering, as such a connection is destroyed under the influence of high temperatures.

- When installing for a long time, the equipment must be checked at regular intervals.

The described rules began to be presented by the PUE. Their observance is mandatory when working. The safety, health and life of people directly depends on this.

Installation Algorithm

Grounding is carried out from the side of the current-carrying conductors, from where the voltage is supplied. Between the connection point and the place where you want to lead the earth, there should be no galvanically isolated converting elements, which include voltage multipliers, stabilizers and transformers.

The operator who sets up and installs temporary equipment must wear protective clothing. This is a transparent face mask, gloves, insulating boots, dielectric foot mat. It is forbidden to work without protection.

All work is carried out in a strictly given sequence:

- Fastening a common or center clamp to an earthing bar. It must be valid and tested.

- Using a tester or indicator screwdriver, the absence of voltage on the current-carrying conductor is checked.

- Visual inspection of the structure and all conductors.

- Test contact with the clamp of the current-carrying conductor.

- Reliable fixation of the conductor.

- Next, a design test is carried out.

The work must be carried out by at least two specialists. This allows in the event of an electric shock to cut off the power supply, provide first aid to the victim and call a doctor. Only professionals with high qualifications and sufficient work experience should be engaged in installation and connection.

The protection method also depends on the load. When connected to equipment with voltages above 1000 V, a special rod made of dielectric material is used. If the voltage is less, work with dielectric gloves is sufficient.

Removing the ground

The procedure for removing grounding is as follows:

- Checking the absence of voltage on grounded areas. Carried out by testers and indicators.

- Disconnecting the clamps from the electrical installation.

- Disconnecting the clamp from the grounding bar.

Before reapplying the load to the installation, remove the portable earthing switch from the area of operation. You also need to check for operability of the standard grounding to which the equipment is connected in the junction box. A working earthing must be installed, otherwise the use of the unit is prohibited.

What to do if there is no standard grounding

In the case of work on an ungrounded installation, a temporary ground loop is made. It is a triangle made in accordance with all the rules for organizing a protective earth. After that, portable grounding equipment should be connected to it. The deputy is made of metal pins, profiles. It is imperative to take care in advance of the device with which the product will be pulled out of the ground after the completion of the repair work.

Instead of such a circuit, you can make another installation in the form of a ground electrode with a return hammer. With this design, you can easily install the rod in the ground and pull it out.

When installing grounding on a temporary circuit, you must adhere to the same rules and recommendations that are given for a stationary grounding bus.

Pole grounding of power lines

The grounding temporary structure for power lines differs from the ground options by using long rods. Also, at the ends of the conductors, instead of clamps, gripping hooks will be placed. There is no standard grounding when working in the field, therefore, a portable design is also used for a certain period. Usually the required set is included in the kit.

The absence of screw terminals results in weaker and less reliable contact with the current-carrying conductor. For this reason, 2-3 redundant ground connections should be made for each high-voltage conductor.

Grounding is done from the ground. The operator stands on the ground, installation from a pole is prohibited.

Power lines are connected by rod single-phase earthing switches. The conductors are connected to each other from the ground at the point of intersection with the ground electrode.