Both new settlers and apartment owners in old panel houses have to face the need to install a socket into a concrete wall. It arises due to the lack of electrical outlets available to residents. When there are only 1-2 nests in the room and an abundance of household appliances, the problem needs to be solved. This should be done by installing new devices, since the use of extension cords and tees will not give the desired effect. Drilling reinforced concrete walls is a difficult and demanding process that requires a special approach and careful preparation.

Preparatory work

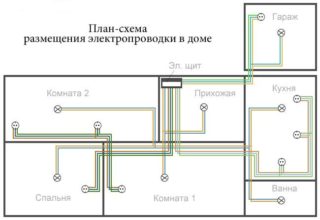

Before making a hole for a socket in concrete, it is necessary to draw up a diagram and carry out calculations. Laying cables is allowed only in vertical and horizontal directions, any diagonals are excluded. If grooves are made, the wire must be pulled into a corrugated plastic tube that is embedded in the groove.

To carry out the installation of internal sockets on your own, you will need the following tools:

- perforator, grinder;

- level, tape measure;

- pliers, wire cutters, knife, hammer, chisel;

- drill for rosettes, diamond crown, screwdriver set;

- indicator;

- narrow spatula, thin paint brush;

- corrugated plastic tube;

- pencil.

From the materials you need to purchase the following:

- a three-core copper cable so that grounding can be made;

- plastic socket boxes;

- gypsum or putty;

- liquid primer for concrete and plaster;

- sockets with three contacts.

To facilitate the work, you should have a stepladder or a stable table to work at height. Protect your eyes and breathing with a respirator and construction glasses. Installation should be carried out with gloves.

Wall markings

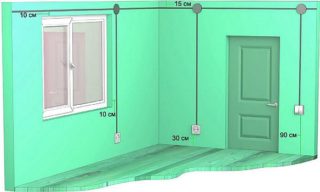

Deciding where and how to install an outlet in a concrete wall should take into account the following factors:

- Locations of previously laid lines. They can be used for connection without being damaged during drilling.

- Arrangement of furniture, as well as possible prospects for moving it or adding new interior items. It is necessary to ensure that the points are not covered by large objects.

- Height. In accordance with the requirements of SNiP, sockets are allowed to be installed at a distance of 20-120 cm from the floor. This provision is based on safety requirements.

After determining the locations of the instruments, it is necessary to apply marks on the walls along which drilling will be carried out.

The markup for a block of several outlets is done in the following sequence:

- The center of the product is outlined, which will be in the middle.

- A flat horizontal line is drawn along this point parallel to the floor.

- From the reference point in both directions, 71 mm are measured, which corresponds to the dimensions of the junction boxes.

To prevent the marks from being erased in the process of further actions, they should be duplicated with a core and marked with crosses.

Making holes

This part of the job is the most difficult, long and dusty part.Before starting it, you need to take flowers, paintings and other small fragments of the interior out of the room. Everything else must be covered with a protective film. It is necessary to drill concrete with the door closed, plugging the cracks with a wet rag.

You can drill a hole for a socket in concrete in one of the following ways:

Installation of a hole for a socket using a hammer drill with a nozzle With the help of a special attachment for the perforator (crowns). The product consists of a shank, a steel nozzle with teeth and a central drill that sets the correct direction of the tool movement. During the drilling process, the bit gets very hot. In order not to burn the incisors, it must be periodically removed and cooled in water. After cutting into the concrete to the desired depth, a cylinder remains in the hole. It is knocked out with a hammer and chisel, or destroyed with a perforator. You can knock out the entire cylinder with a powerful wedge and a sledgehammer. If the edges of the hole are damaged, this is not a big deal - the wall will be plastered. Between the holes, you need to make transitions for laying cables.

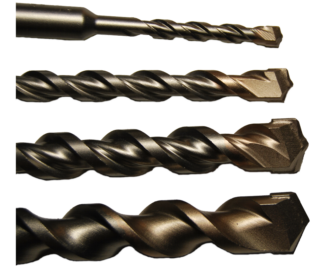

Winning tips Perforator. For work, a set of drills with a diameter of 6-12 mm and nozzles for destruction are used. You can use a drill with a victorious drill, but this is a very long and laborious process. First, circles are outlined, along which holes with a diameter of 6 mm are drilled with a minimum interval. After that, the inner space is turned into a sieve with larger drills. The final stage is the destruction, grinding and removal of the thin walls remaining after drilling. It will take more time here to align the inner edges of the openings.

Cutting a hole for a socket with a grinder Grinder. Instead of a grinder, a hand cutter with a stone disc can be used. The choice in favor of this method is made in cases where the farm does not have a punch, or for some reason it cannot be used. The outer edges of the drawn circles are connected by straight lines - a square or rectangle is obtained. Then cutouts are made with a grinder. The circle should extend beyond the corners by half the diameter to get the correct opening. To make it easier to select the material from the inside, it is recommended to make several additional longitudinal and transverse cuts. It is faster and easier to break up and remove small fragments.

After receiving the holes, it is necessary to adjust them to the size of the socket boxes. For this, a manual or electric tool is used - a perforator, a hammer, a chisel, a straight grinder. According to the results of the work, holes should be obtained that are 2-3 mm wider and deeper than the mounting boxes.

Niches need to be cleaned of stone chips and dust. It is advisable to treat them with a liquid primer to improve adhesion with the putty, which will be used as a filler.

Preparation and installation of socket boxes

Before you start installing the socket, you need to lead the cable through the hole. If you already have it, you should check its performance so as not to do unnecessary work. If there is no wire, it must be cut into the wall using the same tools that were used to make the holes - a punch and a grinder. With a new laying, it is advisable to lead separate wires to each socket so as not to depend on the power limitations of the connected consumers.

Preparation for the installation of a double box consists of the following steps:

- External examination of products, checking their integrity and correctness of shape.

- Removing plugs designed to pass wires and other fragments that are not needed during installation.

- Connection of junction boxes together, if their design provides for such fasteners.

- Fitting a product in a niche. It should freely enter it without tilting and protruding.

- Passing the cable through the holes and fixing the boxes in a suspended state.

To make a socket in a concrete wall, you need to choose the right putty to fix it.It is better to use a material with an average setting speed, so that you can adjust the socket after immersion in the niche.

To place and fix the junction box in the wall, you need to do the following:

- Once again, clean the holes from dust and dirt, treat them with a primer. Wait until it dries.

- Seal the hole through which the cable exits with silicone. This is a protection against insects that can creep in from neighboring apartments.

- Dilute the putty. You need to make it of medium consistency, dense enough to retain its shape, but also moderately pliable so that it can easily succumb to pressure.

- Apply the mortar evenly to the inner walls of the grooves. The thickness of the layer depends on the difference in the dimensions of the base and the back box.

- Keeping the cable taut, press the glass into the hole until it is completely submerged. Its edges should be in the same plane with the surface of the panel.

- Use a trowel and a screwdriver to correct the position and final alignment of the products.

If a solution has leaked into the boxes, it is better not to touch it right away. It is more convenient to remove the fragments of the putty after it has completely hardened. This saves time and does not stain the glass.

Wall decoration

Finishing should begin after the mortar has completely solidified in the drilled holes. If you immediately start sealing the strobe, the socket boxes may move from their place due to the mechanical impact of the cable.

The finishing of the panels is carried out in the following sequence:

- The grooves are cleaned of foreign objects, dust and crumbs.

- Surfaces are treated with a deep penetration primer. If the liquid is quickly absorbed, the operation is repeated.

- A solution of sand and cement is mixed. He is used to seal large dips, chips, holes. After applying the solution, a longitudinal depression 3-4 mm deep should remain.

- Completely dried cement is cleaned of protruding fragments and twice treated with a liquid primer.

- A starting putty is being prepared. It is applied and leveled so that 1-1.5 mm remains for the topcoat.

- The base is cleaned from grains and covered with impregnation.

- The finishing putty is mixed and applied. After it hardens, the wall is rubbed. It should be ensured that there are no traces left from the previously laid strobes.

The final finishing is chosen by the owners depending on their own tastes and the purpose of the room. This can be wallpaper, tiles, paint and other facing materials.

Fittings installation

Connecting the outlet can be done before or after finishing work, the sequence does not matter here. Everything is decided by the expediency and the need for an additional point.

Installation is carried out in the following sequence:

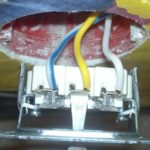

- If the cable is unmarked, phase, zero and earth are determined. The wires are marked. Then the room is de-energized at the input packet switch or by unscrewing the plugs. Use a tester to make sure there is no voltage on the line.

- The outer cable insulation is removed with a knife. Depending on the design of the outlet, it is cut by 3-6 cm.

- The ends of the veins are stripped by 10-12 mm. You need to cut the plastic off them very carefully so as not to interrupt the thin copper wires from which the veins are woven.

- The copper released from the insulation is acid etched and soldered. Plating the metal with tin will prevent corrosion during operation.

- The contact bolts are loosened. Wires are inserted into them. The green-yellow ground wire is connected in the middle. The black or brown phase is attached to the right, and the blue zero is attached to the left. The bolts are tightly tightened, the fixing quality is checked by lightly tightening each core.

- The slack in the cable is folded like an accordion so that it fits freely and compactly in the installation box.

- The socket is slowly and carefully inserted into the hole. After the plank rests against the wall, the product must be firmly fixed.For this, self-tapping screws and spacer legs are used.

- A cover and decorative overlays are installed. This procedure is carried out in accordance with the instructions attached to the product.

- The strength and reliability of fastening the socket and the junction box is checked. To do this, a plug from a powerful electrical appliance is inserted and removed several times into the product. If the work is done correctly, the product maintains a constant position.

In conclusion, current is supplied to the room and the operability of the device is checked.

Features of installation in high-strength concrete with reinforcement

If the sockets are to be installed in panels made of high quality reinforced concrete, special equipment should be used - a diamond drilling machine. The reason is that a perforator drill is powerless against reinforcement, and metal drills blunt against concrete. The way out can be a grinder with a diamond blade, which cuts both of these materials equally effectively. After making the slots, the concrete is broken, the reinforcement is cut off.