Thermal insulation for the electrical network is required, it performs a number of functions. The main task is to prevent direct human contact with live parts, to protect the network itself from thermal, mechanical and chemical effects.

- Is the wire insulation always carried out?

- Requirements for the insulation of electrical wiring

- Coupling and its insulation

- Insulation of conductive cores

- Insulation layer of the shell

- Junction boxes

- Insulation of wires of electrical appliances

- Insulation of wires with electrical tape

- Heat shrink wire insulation

- How to insulate a wire in a wall

- How to use an extension cord safely in the garden

- Precautions

Is the wire insulation always carried out?

Already in the early stages of using electricity, it was known that the wiring would have to be insulated. Today, plastic, rubber and other budget insulating materials are used as insulation, the service life of which will be long.

In the recent past, ineffective but expensive materials were used. There were also bare wires, which were marked with an appropriate sign for people to be careful around them.

Requirements for the insulation of electrical wiring

The material intended for insulation has not only dielectric properties, but also has a protective function. Depending on the installation method and the conditions of use, other requirements may be imposed on the insulation.

- Long service life, high aging resistance.

- High resistance to abrasion and tearing.

- Resistant to thermal effects, especially high temperatures.

- No kinks possible.

- Resistance to chemical attack.

Requirements for the insulating material are modified depending on the mechanical influences of the environment, mechanical stress, conductivity in the environment of use.

Coupling and its insulation

The connector is used when it is necessary to extend the wire, for example, when moving a switch or socket. The sleeve together with the wiring will be embedded in the wall, so its insulation must be airtight. The safest option in this case is to use a heat shrink tubing. When choosing, the degree of its shrinkage is taken into account. As a rule, this part is characterized by a threefold shrinkage, it is important to take this into account when choosing the required diameter. Insulation is carried out in several stages - first of all, the veins, and then the rest of the site.

As soon as the wires are connected, the tube is pulled through to the end of the wire.

Insulation of conductive conductors

The places where the conductors are connected are insulated with ordinary electrical tape, but the contact will be thicker, and it will be more difficult to put a heat shrink tube on it. As an analogue, it is preferable to use a special heat-shrinkable material. Shrinkage is carried out using an ordinary lighter or a construction hair dryer.

Insulation layer of the shell

At this stage, the insulation of live parts must already be completed; for complete and reliable sealing, the sleeve shell is additionally processed. This is especially important when casing sheathed cables or wires. The tube must hide the connection point and be located on the outer insulating layer on both sides by at least 1 cm, otherwise there is a possibility of dust and moisture getting under the factory wiring sheath.

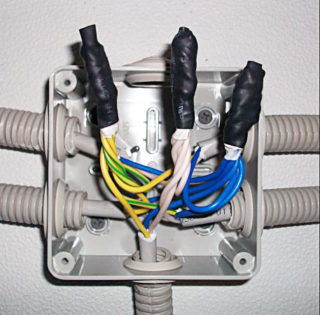

Junction boxes

Contact devices in the intra-apartment network are switching boxes. This design is protected from the harmful effects of the environment by a housing and a cover. The need to insulate electrical wires will depend on the design features of the equipment. If equipped with clamping jaws, no additional protection is required. If this is not the case, a delineation of the conductors is necessary.

The twist connection is most often used in junction boxes that are not equipped with connectors. However, over time, the twist loses its density due to expansion caused by temperature changes and oxidation of the conductors. To do this, twist the stripped ends of the veins tightly clockwise, and then, putting on the cap, scroll it in the same direction with a little effort. The inner cavity of the plastic cap is equipped with a steel cone spring. When rolled gently, it fits snugly and squeezes the contact. The caps can be produced in different colors and sizes, which will allow you to find the right contact.

Making twists designed for heavy loads, before insulating the wires, they are treated with a special substance intended for electrical contacts. This will reduce resistance as well as protect against active oxidation.

PPE insulation cannot provide reliable tightness, therefore it can only be used in a special compartment of the contact device. If in the future it is necessary to connect a new line or replace the lamp, it is enough to simply remove the cap, which cannot be said about the electrical tape.

During work on the line, it is required to turn off the power in the shield.

Insulation of wires of electrical appliances

Insulation of wires with electrical tape

First of all, you need to thoroughly twist all the wires together. If the wire has a large number of cores, it is preferable to simply solder them.

Next, an insulating material is taken and the entire cable is carefully wrapped. It is important that you end up with two layers. It should not be allowed that even the smallest part of the wire remains uninsulated, this will inevitably lead to a short circuit.

Heat shrink wire insulation

Insulating the wires in this way is as easy as shelling pears. But it is important to put on the tube at a time when all the wires are already securely connected to each other. Best used for insulating copper conductors.

After all the wires have been connected, a cap is put on the wire, which needs to be warmed up. It is best to use a building hair dryer for shrinkage, but if it is not there, you can do with an ordinary lighter. In this case, the heat shrinkage should completely tighten on the wire, since the resistance of the insulating layer of the wire will lead to an accident.

Heat shrinkage is used to insulate wires that are designed to operate in humid environments, water, or earth.

How to insulate a wire in a wall

It is required to select the plaster at a distance of 3-5 cm from the damage site on both sides, the depth of the trench is 1 cm. These conditions are mandatory for the smooth and high-quality connection of the damaged sections of the chain. The next step is to disconnect the wires and make an incision in the insulating layer along the center.

Insulating material is removed from the damaged ends of the conductor by 10-15 mm. If the wiring is old, the insulation is likely to be hard and almost impossible to remove with a knife in cramped conditions. Better to use the reflow method.

The ends of the copper conductors are covered with a layer of soldering iron. It is important to tin the conductors very carefully from all sides. Finally, an insulating tube is put on the joint. If a moisture resistant bond is required, the pre-bonded area can be treated with silicone.

How to use an extension cord safely in the garden

To connect garden equipment, IP54 extension cords are required. If the insulating layer has been damaged, it must be sealed to ensure complete operational safety. This can be done using heat-shrinkable tape. It is enough just to wrap the wire with it and heat it with a hairdryer.

When exposed to heat, the insulating substance shrinks, thereby tightly crimping the wire. Also, during shrinkage, glue is released from the inner surface of the insulating material, which enhances the effect. In terms of the quality of the work performed, the heat-shrinkable tape is not inferior to tubes made of a similar material. Another advantage of the building material is that it can be used in a winding way.

Precautions

Before proceeding with the insulation of the wires of the electrical network and household appliances, you must make sure that the network is de-energized. It is recommended to disconnect the voltage using a dedicated circuit breaker. Next, with a flat screwdriver with an indicator, the presence of voltage at the output is checked - the place where the work will be carried out.

When performing work, the quality of the materials used matters. If the material is highly flammable and is afraid of thermal effects, this will inevitably lead to an accident or emergency situations in the future.