The construction of any residential, commercial and administrative building begins with the arrangement of the foundation. The service life of the house directly depends on the type and quality of assembly of this structure. Quite often, the solid base fill method is given priority. This decision is made when working on unstable and heaving soils, erecting massive buildings of brick and concrete. Reinforcement of a foundation slab is the process of giving the foundation strength and resilience sufficient to withstand seasonal fluctuations in the soil. You need to approach it thoughtfully and responsibly, observing the established rules and taking into account all the nuances.

Description and features of the reinforcement of the foundation slab

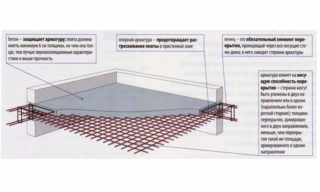

Concrete and steel used in construction have unique characteristics, but individually they cannot be a solid and reliable foundation for a house. The desired result is achieved only by combining them into a single structure, where each component performs its function, while complementing the properties of another material.

Reinforcement of the foundation slab is carried out for the following reasons:

- Concrete has high compressive strength but is not resistant to tensile and twisting loads. The slab is affected by loads from the buildings standing on top and the soil changing its volume. Unevenly distributed pressure leads to plate breakage, distortion and destruction of the building.

- Metal under the influence of pressure can stretch, shrink and twist without changing its internal structure. Having a rigid connection with concrete, the metal frame provides an even distribution of the load over the entire area, deformation of the slab without cracking. In addition, iron prevents excessive thermal expansion of the concrete by keeping it static.

The reinforcement frame for the slab foundation is created in advance, based on the calculations. The process itself is lowering into the mold and fixing the iron frame, followed by pouring a concrete solution. The shape of the frame can be three-dimensional or flat, depending on the thickness of the slab and the approximate weight of the future building.

Necessary materials and tools for work

Reinforcement of a monolithic foundation is an event for which you need to carefully prepare. You cannot save at this stage of construction. Repair of the support system is a complex and expensive process that even specialists cannot always perform.

To reinforce a RC slab, you will need the following tools:

- tape measure, square, level;

- pliers, pliers;

- paint brush;

- a hammer;

- knitting gun or hook;

- marker.

List of building materials:

- fittings;

- knitting wire or plastic ties;

- inserts, spacers and corners;

- acrylic paint or anti-corrosion agent.

The lists are compiled without taking into account fragments of the foundation pit, the creation of formwork, filling, insulation, waterproofing and grouting.

Working with metal carries a risk of injury. It is necessary to reinforce the base in dense deaf clothing, hard shoes, protective gloves and goggles.

Technology and stages of foundation slab reinforcement

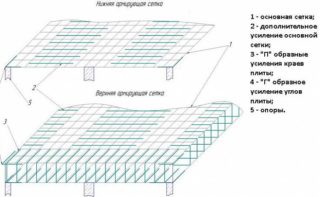

To create a solid and reliable foundation, it is customary to make a two-layer structure. It has two gratings, where the lower one is installed 3-5 cm from the pillow, and the upper one - at the same distance from the surface of the poured slab. Both levels are connected with jumpers. Such a scheme for reinforcing the foundation slab is much more effective, since the volumetric frame is much more resistant to deformation.

When creating the frame, the mesh is made with a constant distance between the rods, regardless of the installation location. The step of reinforcement in a monolithic slab is selected based on the design load to which the base will be subjected. For a brick building, it is taken no more than 20 cm.When building lightweight structures made of shields, beams and foam blocks, an interval between rods of 40 cm is allowed. The optimal step is considered to be up to 1.5 times the thickness of the design slab thickness. In this case, the minimum thickness of the base is 10 cm.

The sequence of laying reinforcement in a monolithic slab:

- Transfer the markup from the drawing to the backfill. Install plastic supports for the longitudinal rods.

- Cut the knitting wire into lengths of 20-25 cm or prepare factory-made loops.

- Spread the reinforcement over the entire formwork area. It is necessary to lay the rods so that at least 3 cm remains between their ends and the edges of the form.

- Install jumpers. For this, hand tools, steel or plastic ties are used. Check for correct assembly.

- Lay the top layer of rods. Where their length is not enough, make an overlap of 30-45 cm, which is fixed with wire.

- Install the upper jumpers. In places of increased load (external walls, columns), the distance between the fragments is halved. This layout will give the base additional survivability.

- Secure the side restraints. These details will prevent the frame from moving from its place when exposed to the solution and at the same time strengthen the formwork.

In conclusion, the correctness of the work performed, the horizontal level of the tiers, the correspondence of the sizes and the strength of the nodes are checked.

After eliminating the errors, concrete must be poured. It is not recommended to pull with this measure, since iron in the open air quickly rusts, and this can lead to the destruction of the reinforced foundation.

Methods for creating a reinforcing cage

You can use one of the following mounting options:

- Phased assembly in the pit. It involves the creation of the upper and lower tier in stripes, when the master moves with his back forward to one of the walls. The work is painstaking, but it allows you to achieve the specified accuracy.

- Grill on the grill. It is used in cases where the slab has a small area, and steel structures are of limited weight, so as not to bend during installation. The procedure requires high precision in calculations and accuracy when joining fragments.

- Laying ready-made sections. The simplest and most effective approach in all respects, when editing can be performed even alone. The essence of the method consists in the manufacture of sections outside the pit, which can be manually brought and laid on supports or put them after laying. In the future, the fragments are linked together.

In some cases, it is envisaged to bring the reinforcement outward after pouring.Mortgages make it easier to attach the load-bearing structures of the house to its base.

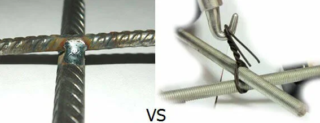

When planning work, it is necessary to foresee in advance the technology of connecting rods and struts. Welding may seem like the most attractive way, but it has its drawbacks. With strong heating, the metal loses its strength, the damaged area quickly rusts. In addition, the joint becomes rigid, causing internal stresses in the slab. When using wire and ties, there is a slight shift in the metal during the pouring and hardening of concrete. As a result, the frame assumes an optimal position in space, the appearance of stresses is excluded.

Rebar for laying in a monolithic slab

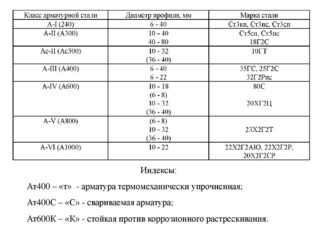

When choosing reinforcement for a slab foundation, one should be guided by the provisions of GOST 5781-82. The document regulates the grade of steel and the class of products that are allowed to be used to reinforce the slab foundation.

It is allowed to use rental of the following classes:

- A 240 - with a smooth surface;

- A 300 - with a periodic annular profile;

- A 400 - with a continuous crescent pattern.

The standard prescribes the minimum diameter of the rods to create the framing. It cannot be less than 0.3% of the length of one side of the slab. For example, with a base length of 400 cm, to create a frame, you need to take 12 mm reinforcement. The diameter of the bridges must be at least half of the material of the upper and lower gratings.

Metal should be purchased only from trusted manufacturers after checking the availability of a certificate.

Possible errors when reinforcing the foundation

Since the foundation experiences the most severe loads, even the slightest flaws are unacceptable in its design and construction.

Inexperienced craftsmen make such mistakes:

- Butt welding, which is an extremely unreliable option.

- Metal-to-ground contact. Corrosion develops, causing the concrete to rupture.

- Ignoring the application of a protective coating to the iron.

- Too great distance between rods and struts. The slab turns out to be weak, deflections are formed.

- Use of wood supports. The wood gets wet and transfers moisture to the metal, which begins to rust.

- Docking in corners instead of using fittings. In places of increased load, this is unacceptable.

Reinforcement technology is simple, but it must be followed exactly. This is the only way to count on a quality result.