Reinforced concrete is the most durable artificially created material from which objects that require a high level of reliability are erected. Such structures include hydroelectric dams, nuclear reactor vessels, bridges, quays and runways. Reinforced concrete is a structure, inside which the steel frame takes on the deforming linear stresses, and the concrete protects it from corrosion and compression. Reinforcement of the strip foundation is the most critical stage in arranging the base of the house, on which the stability and duration of operation of the entire structure depends. There are a number of rules for reinforcing the base, the observance of which will allow you to create a reliable and durable structure.

Features and limitations of the strip foundation

Strip foundations belong to the category of universal support structures that allow construction to be carried out on almost all types of soil. The base is a continuous vertical slab on which the walls of the building rest. The tape can only be a support or perform the functions of an underground structure, when soil is removed from the inside and the floor is poured.

Design features of this type:

- Use for the construction of individual blocks or monolithic construction.

- Possibility of combining with additional vertical supports (screw, reinforced concrete, bored piles) to optimize the distribution of vertical pressure.

- Economical use of materials with minimal involvement of special equipment. The ability to make your own hands.

- Applicability for private and large-scale industrial construction.

- Availability of technologies for use on various terrain and practically any soil.

- High load-bearing properties due to a competent combination of materials, shapes and sizes.

Ribbon designs have limitations:

- Necessarily a closed loop, without which it is impossible to achieve the necessary strength.

- Reinforcement along the entire length and height. Without a frame, a structure is not able to withstand vertical and horizontal loads.

- Depth of placement. On dense soils, it is taken within 10-70% of the freezing level. On unstable soils, the foundation must be laid below this mark.

- Quicksands. In such areas, it is impossible to equip a basement, the expediency of the tape disappears. Instead, slab or pile technology is used.

- Support base area. It must correspond to the weight of the building and the bearing capacity of the soil in order to avoid distortions and subsidence. Tables and formulas are used for calculations.

The advantages of the design are manifested only if a reinforcing frame is installed in it, the rules for the preparation, pouring and curing of concrete are observed.

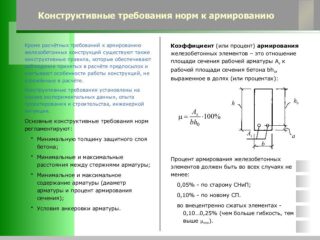

Reinforcement Necessity and Requirements

Concrete has high axial compression resistance and weak tensile resistance. Metal rods are elastic and transfer this property to the foundation. In turn, the hardened mixture protects the iron from corrosion and keeps it static.

During operation, the constituent parts of the foundation perform tasks of different physical properties aimed at achieving the necessary properties of the support system. Concrete resists compression, and steel provides deformation within the design limits. Correct design can reduce the amount of earthwork and mortar consumption. This saves costs and reduces the weight of the base.

The following requirements are imposed on reinforcement:

- a sufficient margin of safety to withstand additional loads that may arise during the operation of the structure;

- the location of the frame so that it does not interfere with the correct supply of concrete mortar into the formwork;

- knitting with a step corresponding to the thickness of the contour;

- it is necessary to lay the sections so that at the end of the pouring the iron does not protrude from the foundation;

- mandatory treatment of iron against corrosion, since rust can break concrete;

- rigid connection of all fragments, regardless of their location.

Reinforcement technology has been proven for centuries. Thanks to its implementation, the service life of buildings and structures was increased by 3-4 times.

Reinforcement materials and tools

In order to properly reinforce the foundation, it is necessary to choose the appropriate tools and fixtures for this. If a mistake is made at this stage of construction, sooner or later it will manifest itself. This will lead to costly repairs or the building being declared disrepair. Reinforcement for the foundation is on sale, differing in features, categories and assembly technology.

Armature

The rods made of black iron, produced in accordance with GOST-5781-82, are considered classics. The production is carried out using the hot rolling method. Products are used without restrictions on the type of construction.

The rods have the following technical characteristics:

- Class. Varies in composition and amount of additives added to iron. There are 6 classes in total, the quality of the metal increases as the indicator increases. If the reinforcement of a strip foundation 40 cm wide can be carried out with rods of class A-I-A-II, then products of class A-III and higher are used for the foundation of a multi-storey building 60-80 cm wide.

- Material. Plastic and steel rods are used in construction. The former are cheaper, lighter, resistant to corrosion, but not strong enough. Metal products are much more reliable, but more expensive, heavier and prone to rust.

- Surface. Fittings are produced with smooth and grooved surfaces. Smooth wire is used for knitting the frame and arranging light foundations. Corrugated structures provide better adhesion to concrete and are used in the construction of heavy objects.

Steel reinforcement is categorized in terms of weldability and susceptibility to corrosion.

Materials to be joined

The easiest and fastest way to tie the frame is to weld its elements. However, only “C” grade steel is suitable for this. Other materials lose strength from heating.

To knit rods quickly and efficiently, you can use the following tools:

- Annealed steel wire, BP grade. According to its characteristics, it can be of normal or increased strength. It is produced in coils or in the form of ready-made loops.

- Plastic clamps-ties. The assembly of the skeleton is quick and easy. The disadvantages are that the products are expensive, do not give a hard grip and break in the cold.

- Plastic ties with steel core. Provide ease of installation and strength of the connection, but are expensive.

To assemble the frame, other devices are also used: side and bottom clamps, inserts for the correct formation of the volumetric frame and maintaining the distance between its fragments.

Knitting tools

It is simply impossible to work with the armature by hand, since muscle strength alone is not enough for such a process. For this, special tools have been developed, thanks to which the installation is accelerated and its quality is increased. If you follow the instructions for use of the devices, the strength of the joints will not be inferior to the welds.

Tying reinforcement for strip foundations can be carried out with the following devices:

- Knitting gun. The device is equipped with wire spools and a spare battery. The tool grips the skeleton assembly, wraps the wire around it, twists it, and cuts off the excess. The device is effective, but quite expensive.

- Semi-automatic gripper, acting on the inertial principle. Acts similarly to a pistol, only part of the wrap-around operations is performed manually by the wizard. The harness is smooth and strong.

- Crochet hooks. They are a universal tool that allows you to perform all actions, including in hard-to-reach places. There are many models of hooks, the choice is made after evaluating their ergonomics on an individual basis. If you wish, you can make a hook yourself, taking factory products as a template.

The device for knitting is selected based on the amount of work, their complexity, their own physical and financial capabilities. It is advisable to have at hand a semi-automatic gripper and a pair of crochet hooks in order to be able to work continuously in any conditions, combining knitting methods.

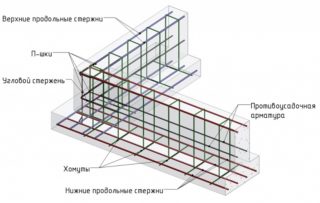

Reinforcement knitting scheme and calculation of materials

When drawing up a drawing of a frame for a foundation, the following rules should be taken into account:

- For the bottom row of the foundation frame, the thickest rods are taken with a minimum pitch of inserts, since the highest pressure falls on these levels. Even for the construction of a one-story house, you need to take products with a diameter of 10-12 mm.

- The corner cannot be a connection of longitudinal elements. In such places, it is necessary to lay bent fragments, and even rods should be attached to them.

- The frame should be at least 30 from the outer sides of the tape. When erecting a base 50 cm wide, the removal of horizontally located reinforcement is 40-44 cm.

- The maximum spacing between the edges of the frame is 40 cm. If the base is wide, a spatial structure with several ribs is made.

- Steel wire with a cross section of 8 mm or a plastic insert of 10-12 mm are used as spacers between vertical and horizontal elements.

- Depending on the dimensions of the foundation, the distance between the transverse fasteners is taken 10-50 cm. Exceeding the maximum value is not allowed.

- With a base height of more than 100 cm, several tiers of the frame are made with a vertical size of 40-80 cm. It is not recommended to increase the height, as this will create complications when knitting the sections.

If the knitting is carried out correctly, during the pouring and hardening of concrete, the structure will take the optimal position, while maintaining the specified linear and spatial forms. As a result, there is no internal stress in the material in the tape.

Reinforcement technology

This process is carried out in the following sequence:

- Structural elements are laid out on a flat surface in accordance with the diagram.

- Installation of the lower horizontal belt. First, the longitudinal elements are joined across, then vertical clamps are attached to them.

- Assembly of the top level of the section. Ties or wire are used. The strength of the connection is checked.

- Manufacturing of corner sections. Additional racks are installed on them, since these places take the maximum load.

- Fastening spacers to the rods, which will ensure the correct and stable position of the frame in space.

- Assembly, laying and fixing of subsequent tiers, if the construction of a buried tape is being carried out.

- Installation and fastening of pipe sections in the formwork, which will be used for laying communications or as air.

Finally, the concrete is kneaded and poured.