Waterproofing compounds are used to protect concrete, reinforced concrete or metal structures from the effects of water. Bitumen-based mixes are popular for their high performance and low cost. The application of mastic to the foundation of the building will prevent the destruction of the structure and increase the service life.

- What is bituminous mastic for waterproofing

- GOSTs and varieties of material

- With mineral fillers

- Bituminous rubber

- Bituminous-polymer

- Bituminous emulsion

- Bituminous rubber

- Building bitumen

- Properties and characteristics of mastic

- Application rules and features of working with the material

- Calculation of the consumption of mastic

- Application area

- Foundation waterproofing technology with bituminous mastic

What is bituminous mastic for waterproofing

Mastic containing construction bitumen is intended for the protection of concrete and metal structures. In addition to bitumen, the mixture contains synthetic and mineral modifiers that improve physical and chemical characteristics. The plastic material is easily applied to any surface, and the process can be mechanized using a spray gun.

According to the method of application, they are divided into two types:

- hot, requiring preheating;

- cold - ready to use or requiring dilution with a solvent.

By the number of components, there are two types:

- One-component - the composition is ready for application, but after opening the sealed package it quickly hardens, you must immediately use it.

- Two-component - bitumen and solvent are packed separately, diluted in the required amount.

In appearance, the composition should be viscous and homogeneous, but in some brands special inclusions are allowed. The universal product is used in all areas of construction.

GOSTs and varieties of material

Specifications for roofing and waterproofing bitumen mastic are written in GOST 30693-2000. In the document, building materials are classified by the main characteristics:

- appointment;

- initial components;

- type of diluent;

- mode of application;

- the nature of the curing.

According to the standard, waterproofing mastic must withstand exposure to water for 10 minutes at a pressure of 0.03 MPa. Products must have transport markings in accordance with GOST 14192.

The waterproofing material is evaluated during tests according to the following indicators:

- softening temperature;

- viscosity;

- flexibility;

- adhesion strength to the base;

- water permeability;

- dry matter content.

Bitumen is a material of natural origin. Various substances are added to change and improve its characteristics in the process of making mastic.

With mineral fillers

Bituminous rubber

Ready-to-use multicomponent material containing bitumen, rubber crumbs, modifying additives, mineral fillers. Such mastic does not soften at elevated temperatures, and at negative rates, it does not crack. An organic solvent provides a liquid consistency.

Bituminous-polymer

The inclusion of polymer components increases the elasticity of the mastic.The dried layer is able to stretch and recover. It is characterized by excellent adhesion, long service life, and heat resistance. The material is used for roofing, floor treatment, waterproofing of foundations, tanks, pipelines.

Bituminous emulsion

Emulsions are water-based formulations. Their advantages are: lack of odor and toxic components, fire safety, quick drying. The material is used for the device of internal and external waterproofing. Emulsions with the addition of latex provide durability and elasticity of the coating. The filler stabilizes the properties of the mastic and ensures the durability of the applied waterproofing.

Bituminous rubber

The composition, due to the addition of synthetic rubber and mineral fillers, has a high viscosity. It is suitable for repairing cracks and for sealing roof joints. The material is designed for operation in the temperature range from -30 ° to + 130 °. Waterproofing with rubber is flexible and durable, it does not require prior application of a primer.

Building bitumen

By origin, the material is natural and artificial. Construction bitumen is intended for concrete work. There are special grades for roofing and road surfaces. The material is sold in briquettes to make a viscous waterproofing compound, it is poured with a solvent or heated to melt. Plus bitumen is an affordable price.

Properties and characteristics of mastic

Cold applied bituminous waterproofing mastic is a semi-liquid black compound. Its consistency is ideal for vertical surfaces. The hot-applied material is available in solid form. After heating, it becomes fluid, it is recommended for horizontal structures, gluing roll materials. Thanks to the application of coating insulation, the surface is not exposed to moisture, mold and microorganisms.

The main advantages of the material:

- Ease of Application - Brush or roller can be used to spray rig. The job does not require professional skills.

- Excellent adhesion to any type and quality of surface

- Creation of an elastic, seamless coating, which is important for waterproofing.

- The use of additives makes the mastic frost-resistant, immune to ultraviolet light.

- Waterproofing works can be carried out at any time of the year.

One of the most famous and high-quality products for waterproofing is TechnoNIKOL AquaMast foundation mastic.

Application rules and features of working with the material

When using bitumen-based lubricants, the following rules must be followed:

- For dry soil, the thickness of the foundation waterproofing layer with a depth of 2 m is 2 mm.

- With an increase in the depth to 5 m, a four-layer application of the composition with a total thickness of 4 mm is required. Bitumen-polymer mastic is recommended.

- On damp and heaving soils, the coating insulation should be reinforced with fiberglass.

- It is forbidden to carry out work during precipitation or immediately after rain.

- When using hot bitumen, clothing is required to protect the body from the ingress of molten drops, a respirator.

Bituminous compositions with solvents belong to the group of flammable substances. When using them, you must follow safety rules: do not smoke, do not use open fire. In the process of applying, the hands are protected with gloves, and the eyes with glasses.

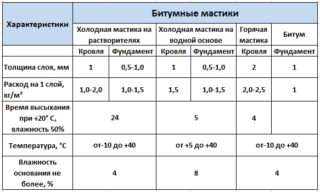

Calculation of the consumption of mastic

- type of mastic;

- air temperature;

- method of application;

- the percentage of volatiles in the composition.

For cold application, the remaining dry matter must be taken into account. The higher the indicator, the lower the consumption of the composition. Hot bitumen does not shrink, so the layer thickness does not change.The recommended thickness of the foundation coating is 2 mm, which corresponds to two layers of waterproofing. The second layer is smeared only after the first has dried. Average consumption of the train is 2 kg / kW. m. Usually, manufacturers indicate the exact data on the packaging, therefore, by calculating the surface area of the foundation, you can determine the total volume of the coating waterproofing.

Application area

Scope of application of bituminous mastic:

- moisture protection of foundations, pools, pipelines, piles, basements and other structures;

- anti-corrosion treatment of metal products;

- antiseptic treatment of wooden structures;

- roof installation;

- laying tiles in rooms with high humidity;

- gluing roll materials

Bituminous mastic is used for waterproofing new foundations and for renovation work. Some types are used for gluing roll materials.

Foundation waterproofing technology with bituminous mastic

- Preparation of the concrete surface - the structure is leveled, cleaned of dust and dirt. Sharp protrusions are cut off, deep cracks are putty.

- Primer. The base is treated with a primer, a liquid bitumen-based composition. They buy it in hardware stores or bred existing mastic. The penetration of the primer into the pores of the concrete ensures high-quality adhesion of the waterproofing and the base, and reduces material consumption.

- Waterproofing. The container with the composition is opened before use. Experts advise to warm up the mastic to 32-35 ° so that it lies smoother. The hot-applied material is heated to 150-180 °. Apply the composition with a brush or brush. The layer should be uniform, cover the entire structure without gaps. Bitumen is applied to the foundation from top to bottom, the strips overlap each other. The second layer and subsequent ones are spread after the previous one has dried. For emulsions, the waiting period is 5 hours, for the rest about 24 hours.

After completing the waterproofing, the foundation is insulated with expanded polystyrene plates or backfilled with sand and gravel. A monolithic layer of bituminous insulation needs protection from mechanical stress.