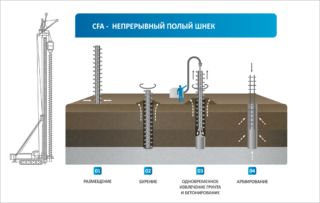

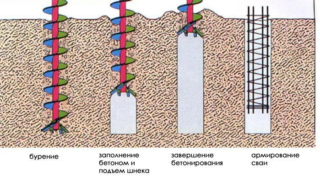

The technology is used for foundations of civil and industrial structures. Bored piles are made by pumping concrete under pressure into the well. The mixture is introduced by means of a screw, then the frame from the reinforcement is installed at the level of the mark according to the project. Reinforced concrete structures are made with a diameter of 12 - 30 cm and lowered to a depth of 20 meters.

Installation of bored piles (BIS)

Dense concrete grades from M400 and more are used, the volume of water is 40 - 70% of the volume of cement. Concrete should gain strength 15 MPa after a week of hardening, 30 MPa and more after 28 days. Piles are reinforced with volumetric frames or single rods are laid inside. In critical cases, metal pipes are used or a combined base is made. The type of reinforcement cage is taken by calculation in accordance with SNiP 2.02.03-1985.

Concrete is prepared on site or delivered from the factory, and the delivery time should not exceed 15 minutes. In the process of arranging, the speed of rotation of the auger and the number of blows when deepening the shell are carefully controlled so as not to select excess soil. Otherwise, there will be an overexpenditure of materials to replace the excavated earth, and the reinforcement may be installed at the wrong height. The metal frame is buried directly after removing the drill or put into the concrete mixture.

Varieties of bored piles

The difference between the LSI is in the way of filling the well with the solution. The standard technology for making an injection pile varies in different cases and depends on the quality of the soil and the characteristics of the structure.

Types of bored injection casings:

- wells without casing;

- passage with the installation of a metal shell;

- with screw immersion.

The first technology is used in sparsely watered soils, while the auger selects the ground, and the concrete pump delivers the solution into the face. The diameter of the bit and the conveyor is selected. Upsetting from pipes is used in swelling and eroded soils, while the strength of the element increases, concrete is saved.

Screw piles do not require an initial drill pass. The pipe is supplied with blades and is screwed into the required place to the required depth. LSIs are of a hanging type, there are also piles-racks, which are supported by a base on a stable soil layer.

No additional well casing

The advantage of the method is that its productivity is 5-10 times higher than the method with casing installation. Due to the pressure of the solution, the compactness of the soil around the pile increases, at the same time the walls of the passage are compacted, thereby increasing the strength of the rod.

The operating time of the equipment is reduced, which leads to an improvement in the environment, if the installation is carried out in a city environment. Pile installation works without casing are carried out with less noise generated, becauseno need to remove soil from the surface of the auger.

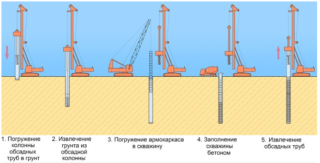

Well cased

The essence of the casing technology of bored piles is the use of sectional reusable pipes. The collector elements are lowered as the passage is drilled and removed after concreting the next section. Sections are fastened using technological joints or by welding.

Drilling is carried out by rotation, impact or vibration, or using composite methods. For this, drilling machines, jacks and rotators are used. The barrel is cleaned after reaching the desired mark and the reinforcing cage is fed down. Concreting is carried out with continuous compaction of the mixture to remove air bubbles.

The order of reinforcement and mortar supply may vary depending on the technology chosen by the designers for arranging the pile foundation. Install inclined or sheer racks in cramped conditions where no other technique can be used. Casing technology is used in the vicinity of neighboring buildings, in unstable soils, in the bottom of water bodies.

Screw-packed

Screw-down injection piles have the following advantages:

- low casing cost and low labor costs;

- fast foundation construction;

- the ability to install yourself;

- no preliminary excavation required.

Screw piles are often chosen for the construction of a private house. The blades are placed not only at the end, but also over the entire surface of the pipe, if the soil is loose on the site. The casing corrodes over time and reduces the protection, in addition, the pipe is difficult to screw in strong layers, for example, rocky.

LSI advantages

LSIs are placed at different depths, which are selected by calculation, while the diameter is determined depending on the load of the aboveground structure. The no-casing method saves money due to the absence of metal shells. This option is used everywhere where there are water-saturated soils. In dry concrete it quickly hardens (gives off moisture), and there is no way to fully place the reinforcement inserts.

Auger excavation of the earth allows you to simultaneously fill the passage with mortar, therefore, concreting begins immediately after reaching the depth mark. This type of packing excludes shedding of the walls of the bottom hole and the collapse of the side layers, therefore it is often used close to existing foundations.

The LSI technique is carried out not only for new construction, but also when adjusting the slope of a sagging structure.

Installation equipment

The insertion of the rods is carried out using a special technique. With the help of improvised devices and tools, you can also supply drill rods, but only for small suburban-type buildings.

Different installations based on the power unit differ in technical parameters and power. Attachments with a powerful pump are mounted on any vehicle. Used self-propelled MBU - mobile drilling rigs with wheeled or tracked chassis. For the construction of buildings, automobile platforms are used more, because they are more mobile.

The base column contains elements:

- auger drill;

- rotator;

- swivel;

- metal mast;

- hydraulic lift.

Drilling machines are rotary and fixed. The first ones develop several perimeter passes from one point, and the second type requires relocation after each well.

Execution technology

Drilling transfers loads to the soil mass, therefore there is a limitation on the simultaneous installation of a certain number of piles. If the distance between the rods is less than the standard value, the device of the adjacent rack is allowed after the mortar has hardened in the previous barrel.

It is necessary to ensure that layers with pebbles or boulders do not meet on the path of the drill. The drill tip may deviate as it passes through such bedding and the pile will not be correctly piled. Drilling may stop due to difficulty to overcome, or the tip may collapse.

The concrete pump develops a pressure of up to 25 - 30 atmospheres and the injection is carried out until the mixture comes out of the bottom hole. The volume of the solution is 1.5 - 2.5 from the cubic capacity of the well. If more concrete has gone away, the feeding is stopped until it hardens and a crimping is done. The situation arises with weak soils or in the absence of casing.

Reinforcement of the foundation with bored piles

Reinforcement of foundations in an emergency state with the help of injection shells is done after cracks appear on the walls, which indicates subsidence. Strengthening the building support is necessary when performing a floor superstructure or increasing the load on the floor of the building.

Stages of strengthening the supporting part of the building:

- study of the object, design calculation to find the required diameter and length of the rods;

- preparation of the site for work, installation of drilling equipment;

- erection of an emergency girder grillage around the perimeter of the existing foundation;

- drilling of passages, filling of shells with mortar with reinforcement and pressure testing;

- leveling the ground and arranging the blind area.

The work is carried out by specialists, tk. without technical knowledge, it is possible to destroy the base and achieve a weakening effect.

Recommendations for use

LSI is suitable if it is not possible to make piles by driving. At the same time, the surrounding soil is weakened and the earth flows into the trunk, which causes an increase in the volume of production and an increase in the working diameter of the pile.

Drilling rods are used in the case of:

- strengthening the supporting part of the building, pit walls, retaining walls;

- erecting a foundation in soils with complex characteristics;

- construction in a densely built-up area;

- elimination of the slope and subsidence of the building.

Calculation of the rack involves collecting loads and determining their type. If shear, torsion, or rupture is suspected, in addition to compression, reinforcement is applied along the entire length of the shell. Before choosing, a survey is carried out to find aggressive water flows in the soil and determine their effect on the material of the rack.