The construction of the base is a costly process, the price of which is 10 - 17% of the total cost of the building. If the building is light, small in size, you can build a house without a foundation. The market offers lightweight portable boxes made of wooden beams and wall panels, which are erected on the ground or a small base of various materials is arranged under them.

Foundation functions for construction

The base must be stable, not deform from loads and evenly transfer forces to the ground under the sole. The type of foundation is determined by the weight of the building, and the type of soil also has an effect. Sandy and rocky soils are considered a strong base, which do not retain moisture and do not swell in frost, and clays require a drainage system.

The foundation is insulated from the soil and the wall of the house with moisture resistant membranes to protect the structure from dampness. Insulation of the base makes it possible to maintain a comfortable microclimate in the premises of the first level and in the basement. The base in the form of a strip foundation or on piles protects the frame house from distortions, tilts and subsidence, provides a stationary position.

The main advantages of houses without a foundation

A practical building without the usual massive support is acceptable and is more often erected on a cushion of rubble and sand. Such a podium protects the house from ground movements and the rise of moisture on the walls of the building.

Pluses of building without a base:

- small material costs;

- work regardless of the season;

- raising the building above the ground and flood protection;

- erection on different types of soil;

- implementation of non-standard wall planning;

- construction speed.

The prepared light base protects the house from the ingress of soil moisture, snow drifts and heavy rainfall. Insulation prevents the outflow of internal energy into the ground.

Overview of alternative technologies

The construction market offers standard construction solutions without a foundation, which include advice on the weight of the structure, dimensions. Experts give recommendations on the choice of materials and construction technologies. The customer turns to the designers to create their own project, the specialists will calculate not only the foundation, but also the entire private house.

Main technologies:

- on the ground;

- stone base;

- tire foundation;

- brickwork;

- sand and crushed stone pillow;

- soil-cement blocks.

With baseless construction, attention is paid to the creation of a bulk slab and the location of communications under the building. They are taken out of the building or isolated under the house to reduce repair and maintenance costs.

Soil base

Not all soil types are suitable for building without a foundation. Lands with stable characteristics are suitable, these include rocks, chernozem, sandy and sandy loam soils. The density of the layers is 12 - 15 kg / cm², so the layer will withstand the house without a reinforcing layer. The disadvantage of the soil base is that it cannot be done on heaving soils.

Work order:

- The vegetative layer of the earth is removed, a foundation pit is dug around the perimeter to a depth of 20 - 25 cm.

- The bottom is cleaned, formwork is placed and a layer of clay is poured to the level of the surface.

The accumulated clay layer takes on the weight of the house. Before laying the lower beams, 3 layers of roofing material are laid on bituminous mastic or melted resin and styrofoam, expanded polystyrene are laid. The insulation must be moisture resistant.

Boulder base

Fragments of mine workings in the form of large stones are used. It is advantageous to build such bases on heights where there is natural material.

Scheme of building a house without a foundation:

- They make markings on the ground, sort and store stones in order to make a strapping from large elements along the contour.

- They dig trenches under the walls of the house and lay large stones first, then move on to smaller boulders.

- For fastening the elements, concrete with a fine-sized filler or clay mortar is used.

- The beams of the house rest on the largest stones, which are laid in the corners and at the intersections of the walls.

The base made of boulders turns out to be strong, its reliability is comparable to that of a monolithic foundation. For ventilation, there are gaps in the masonry, natural materials are not afraid of moisture.

Tire base

Such houses stand for a long time, despite the unusual foundation. Laying in the form of a sand and gravel pad dampens vibrations and shifts in the soil, and a waterproofing layer prevents rotting of wooden parts.

Work order:

- A pit is being dug to fit the size of the building.

- A layer of sand and crushed stone with a thickness of 20 and 15 cm is poured onto the bottom, respectively, spilled with water and rammed.

- Roofing material is laid in 2 - 3 layers.

- Tires of the same height are laid on the top layer so as to fill the entire area under the building.

Wet sand, free of debris, is poured inside the tires and in the intervals between them. A kind of base has sufficient bearing capacity to withstand a country house without a foundation.

Masonry base

The foundation is suitable for one-story frame-type buildings on a wooden frame made of bars or logs. The erection of such a support is a laborious process, since small elements are used, which are connected in series on the solution.

Used red baked brick, which is water resistant. The white silicate material is not used because very hygroscopic. Laying is carried out with bandaging of horizontal and vertical seams, the height of such a base is 0.4 - 0.6 meters.

Sand and gravel base

The construction of such a foundation resembles the construction on the ground with a layer of clay, but instead of it, a sand-and-gravel backfill is made, which is stronger. A pit is dug into the ground 0.6 - 0.1 m deep, depending on the weight of the building. Arrange drainage to drain moisture away from the base and reduce soil swelling.

The gravel is laid in a thick layer to a height of 5 - 9 meters. Each layer is moistened with a hose and tamped with hand tools. The bedding has good strength properties. The top is covered with sand, which is laid until it stops waking up inside. The top of the bulk base is monolithic with a layer of lean concrete, having previously installed waterproofing.

Base from soil blocks

The elements are made from sand, clay and cement. Blocks are a common material for supporting lightweight structures. The solution is laid out in removable molds and kept until dry. Organic impurities in the soil significantly reduce the strength characteristics of the elements, but the properties obtained are sufficient for the construction of a small base for a suburban building.

A bedding of gravel or crushed stone is made to strengthen the earth's surface, spilled with cement milk.Along the perimeter of the walls, blocks are laid out on a solution with bandaging of seams to a height of about 0.5 meters. The top of the masonry is insulated with a waterproof membrane to keep the walls dry.

DIY instructions for building a house without a foundation

The use of wall panels on a cobbled frame is promising. Such buildings are lightweight, easily modernized and repaired.

Without a foundation, you can build houses from the following materials:

- profiled and glued beams;

- chopped from gun carriage and logs;

- rounded and planed logs;

- multilayer panels.

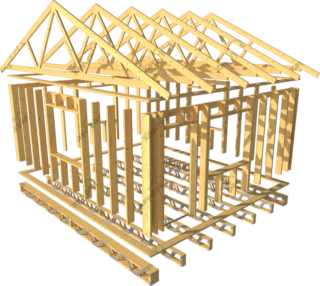

A standard frame house is assembled from racks, lintels, beams. The frame is sheathed with panels inside and outside.

Wooden house

Practical species of spruce, pine and other conifers are used, the material protects the interior from wind and moisture, due to the content of resinous components in the wood. Glued laminated timber, bent connected beams and other molded profiles for the construction of cottages, gazebos, baths and other structures are produced from wood.

Wooden houses are placed on lightweight foundations so as not to increase costs with a massive foundation. Be sure to arrange horizontal insulation from moisture in order to exclude damage to the walls from decay.

Frame house

Wood is excellent for making shield materials. The technology involves the construction of frame-panel, panel and frame buildings.

Produce sheet structures for sheathing frame elements:

- moisture resistant impregnated plywood;

- chipboard chipboard;

- sawdust-shaving blocks OSB;

- hardboard;

- fiberboard fiberboard with a laminated surface.

Insulate the structures of walls, ceilings, roofs. For this, mineral wool, ecowool, polystyrene and other materials based on it are used.

A very interesting topic was touched upon, for example, my father, for example, I think I also made the foundation light, conditionally dug out the perimeter with a tape, it was covered with sand and spilled water from the ground level through broken bricks with a cement mortar of 40 centimes from the ground level and the house still stands on this , and another conditionally foundation is generally made of rammed sawdust with formwork, and also to this day they live in it and have survived thanks to permanent residence and it is due to this that everything has been preserved, the place of origin of Ivanovo.

Excellent! A frame house on piles is not new. Previously, a filling filling was added to such buildings along the perimeter with breaths.