The gazebo must have a foundation so as not to settle over time and to maintain the integrity of the structure. The base is made solid or consists of separate elements. A light pavilion is built from different materials, depending on which the foundation for the gazebo is selected. The wooden structure stands firmly on the pillars, while the brick walls are based on a strip support. In unstable soil conditions, a solid slab is poured.

Base materials

Concrete is used for heavy buildings, for example, buildings with solid brick, stone, cinder-concrete walls. The material is durable, does not crack in the cold and withstands stress well. Crushed stone bedding with a rammer serves as the basis for light, openwork gazebos with a canopy made of polycarbonate, tarpaulin, canvas.

The base is formed from separate reinforced concrete blocks, which are connected by welding of embedded parts. Pillars and glasses are made of brick or wood impregnated against decay. Wood is used for foundation beams. Metal purlins are rarely used due to their high cost. The reinforcement is installed in monolithic structures to increase the flexural strength.

Varieties of foundation for a gazebo

The type of base base depends on the type of soil. Rocks and sands do not swell when wet, so the bases are made up to 30 - 50 cm deep. Problems arise with clay soil, which swells in frost and deforms the frame of the gazebo. Under heavy buildings, the base is deepened no less than the amount of soil freezing.

Insulation is done along the top of the tape, pillars. Mineral wool material is used or expanded clay, slag are added to the concrete composition so that the floor of the gazebo has a comfortable temperature.

Tape

This type of base is made of concrete, reinforced concrete, prefabricated blocks are used.

Step-by-step sequence of work:

- a trench of the required width is dug along the perimeter (not narrower than the wall);

- 5 cm of sand, 10 cm of crushed stone of the middle fraction are poured to the bottom, the layers are compacted;

- the walls of the trench serve as formwork, concrete mixture is poured here using electric vibrators;

- the surface is covered with sawdust, which is moistened once a day for 28 days (the period of gaining 100% strength).

In the thickness of the concrete, a reinforcement frame is placed or longitudinal rods, metal strips are laid. Such inserts are used for capital gazebos with filling the openings with frames and a powerful roof.

Monolithic

A solid slab is made under the entire floor area and does not require a screed under the covering.

The option refers to costly bases, therefore it is used where there are clay soils, swampy lands, during the winter there are sharp temperature changes from frost to thaw.

A monolithic slab is necessarily reinforced with longitudinal bars of corrugated wire rod or welded mesh in order to increase adhesion within the material.

The thickness of the base is chosen depending on the load and is more often taken according to the project.

Columnar

This option is economical, while the supports are made of different materials.Used bricks, concrete, metal pipes are used in combination with wood and insulated concrete. For each element, a hole is dug, an underlayment is made at the bottom and a support is installed.

The top of the glasses is connected with a wooden or metal bar, along which walls of various materials are erected. The bottom of the pillar sometimes expands compared to the top if an increase in bearing capacity is required.

On screw piles

Such a foundation for a wooden gazebo is made only in the case of unstable soil and a large weight of the structure. Usually piles are made of reinforced concrete or combined with wood and rolled metal (Tavr, I-beam, channel).

Piles are:

- hanging - if the stable ground is deep;

- rack-mount - when the solid ground is shallow and the force is transferred directly to it.

Driven options involve lowering the finished element into the ground to the required depth. For rammed piles, channels are made, which are filled with concrete. The grooves are designed to transfer pressure from the building to the depth to the solid soil.

Brick

Of the material, tape and columnar bases are made on a cement-sand mortar. Extended variants are almost never encountered, because for the foundation, you need a ceramic brick that does not absorb moisture from the soil.

Red clay material is expensive, concrete is cheaper. Brick glasses require mandatory reinforcement with embedded rods in the seams inside the masonry. Sand-lime brick is not used for foundations.

From scrap materials

Small and open pavilions do not require a massive base. A 4x4 gazebo with your own hands on a columnar foundation can be made from improvised means. Used prefabricated blocks or pieces of floor slabs are used, you can install dismantled wooden beams from the roof of an old house.

Old car tires are placed under the corners of the gazebo, which are filled with concrete mortar, such supports can withstand the weight and do not deform. As metal inserts of the strip foundation, cuttings of channels, corners, which remained after welding of supporting structures, are used. Broken tiles, ceramics, bricks, screed pieces are used as aggregate in concrete instead of gravel.

Preparation and construction stages

A drawing is being prepared for laying a trench or installing individual pillars. Work begins with cutting off the vegetation layer and leveling the surface of the construction site.

Step-by-step instructions:

- on the surface of the soil, the place of the trench is marked with the help of a tape measure, a square, you can use a theodolite to create right angles;

- marking places are marked with fishing line or nylon thread;

- when digging holes, a water level is used to make the same depth of laying, or a level is used;

- concrete is prepared in a concrete mixer or trough and filled in layers into columnar pits or trenches.

In light pavilions, there are rarely sewers, but if necessary, pipe passages are left in the thickness of the foundation. When marking, the distances along the diagonal of the rectangle are checked so as not to distort the configuration of the gazebo in the plan.

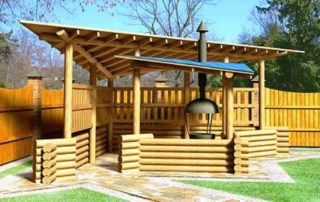

Construction of the foundation for a gazebo for barbecue and barbecue

Such a structure has a cooking stove or hearth for cooking kebabs, roast meat, fish and poultry. In the gazebo, two bases are performed that do not depend on each other. One foundation is erected under the walls of the building, and a platform is also made under the furnace, the dimensions of which are 20 cm larger than the hearth on each side.

A separate base is not required if the base for the gazebo is made in the form of a monolithic slab. The furnace support is made of refractory bricks, concrete, reinforced concrete, metal. You can not put a tree, because this will increase the fire hazard. The thickness of the base is taken by calculation, which takes into account the weight of the stove, the mass of a pipe made of metal or brick.

Do-it-yourself cheap foundation option

Inexpensive foundations are arranged only for light garden forms of small size. A simple option is made in the form of crushed stone bedding on a sandy pillow. The trench is dug 20 - 30 cm deep, the sand layer is about 5 - 7 cm. The rest is covered with rubble. Expanded clay and slag are not used, because have low strength.

During tamping, the layers are spilled with water to firmly shrink the stones. After that, cement milk is made (an aqueous solution of a binder without sand and other fillers). The liquid solution is poured onto the surface and solidifies there. On the third day, the top is covered with two layers of roofing material and the construction of the walls begins.