The question of choosing a support for a house arises if the construction is carried out on an area with a steep relief. If such an array is loaded, collapse may occur due to a change in the natural balance of forces. The foundation on the slope is built using a special technology, before starting work, the calculation of loads is performed taking into account the angle of inclination of the surface, the level of groundwater.

The main types of landslides

The layers on the slope shift due to the absence of reinforcing structures or retaining walls, sometimes the movement begins in a flood or after the building is fully loaded. The balance between directed gravity and restraining forces is disturbed.

External factors cause landslides:

- water washes away the slope and the steepness increases;

- the foundation slides on the underlying soil;

- liquefaction of the land contributes to the appearance of landslides;

- collapse occurs after the breakaway of the soil massif;

- slow landslides are noted as a result of sliding of viscous and dense layers at different times;

- there are seismic shocks.

Dangerous rock displacements occur on the slopes of the valleys, where the section shows alternating aquifers and impermeable layers. Rainwater saturates the soil and increases its weight. The load exceeds the restraining forces of friction, the masses shift relative to each other.

The stability of the land on the site is increased by leveling the slope. Build up embankments or cut off elevated areas. The lower levels of the foundation are drained to draw moisture away from the foundation in an area with a slope.

Rules and features of building a foundation on a slope

The foundation on the slope is done differently than on the plain. The support is endangered by water and precipitation moving from above and washing away the base. The stability of a building is reduced if water erodes the soil in the area of the strip footing on a slope. Serviceability suffers from changes in topography at high humidity.

The soil crumbling is eliminated by strengthening the base, for which the following methods are used:

- the mechanical version involves the installation of steel struts on an inclined plane and the construction of walls;

- planting of bushes and trees with an extensive root system.

The second method is recognized as effective, while the issue of improving the site is being resolved, but the method takes time for the plantings to develop. Attention is paid to the lower area of the base.

For a slope of less than 10%, reinforcement can be omitted, but with an increase in the indicator, a sheet pile row is installed. For supports, additional piles are arranged, which are located relative to the plane of the slope at a right angle, and their depth exceeds the level of the standing soil water.

Choosing the type of foundation

Each foundation for a slope house has different technical characteristics, but the supports are united by a single requirement for their stability.

Three types of foundation are used for a building on a slope:

- monolithic tape with a stepped transition;

- pile with upper strapping in the form of a grillage or slab;

- support from pillars.

Preliminary surveys of the soil are carried out. If there are no problem areas, a strip foundation with one or two shallow steps is allowed.A strong slope requires a base with a gradual increase in the height of the ledges, if the cut and increase in height are irrational. So the support can withstand great forces from the side of the slope.

Sometimes there are soil problems on the site, for example, a wide variety of layers or layers prone to heaving. Then a reinforced pile foundation is arranged so that it rests on stable ground.

Tape

A monolithic tape strip is performed where there is no large freezing depth. The scale of the foundation is determined by the point where the freezing of the soil ends, the size of the bulk foundation is added to the indicator. Be sure to do the reinforcement of the stepped foundation.

A stepped base requires a lot of materials and metal for the structure of the frame, because the upper plane of the support should be at the same level throughout. Sometimes the height of the foundation in the lower part of the slope reaches 2 - 2.5 meters, therefore, the labor intensity of the work also increases. But a stepped support is more economical than a solid tape, which would be carried out at the same depth along the entire length.

The difficulty lies in the installation of the formwork of a complex configuration. In the places of joining of steps of different heights, vertical elements of the reinforced frame are additionally provided. In the lower part of the mountain, it is better to make a support wall to the height of the protruding foundation mass.

Columnar

This type is used on a slope or under a mountain, sometimes placed between hills, if the construction of a house is envisaged there. The technology for erecting pillars is almost the same as a device on a flat platform, but for columnar supports, a lateral load of even a small force is not allowed. Before installing the pillars, the terrain is leveled to the characteristics of the horizontal plane.

Pillars are not used as a foundation:

- with elevation differences of more than 2 meters;

- in the case of sliding layers;

- in clays and peats;

- with a large weight of the structure.

Vertical columnar columns are economical, the material is monolithic reinforced concrete, brick with reinforcement, stone, pipes. For installation, pits are made, the depth of which reaches a stable soil layer. Supports are placed at different heights, which depends on the location along the slope of the terrain.

At the top and bottom of the platform, a trapezoidal tape of concrete is made as a retaining wall. The pillars are combined with a common grillage to level the upper cut.

Pile

In case of difficult terrain, high humidity or close proximity of the soil liquid, screw piles are used on the slope. Paddle rods require a special technique to install the elements. The pile foundation is made with a grillage or a reinforced concrete slab, located on vertical elements. This element gives stability to the foundation block.

The advantage is the small volume of excavation and the speed of construction. Depending on the steepness of the plane, piles of different lengths are placed; the condition is support on a soil layer with stable characteristics. The impossibility of arranging a basement in the house is a disadvantage.

Pile supports are suitable for wooden log cabins, the scheme works well for frame houses, where the bearing line is made longitudinally. Screw piles with slab foundations on a slope are sometimes the only correct option.

Calculated actions

The calculation determines the type of foundation of the structure, taking into account the slope of the slope and soil indicators. The depth of the laying is taken according to the level of freezing and the mark of groundwater. The higher the height difference of the strip base, the greater the laboriousness of the construction, therefore, a combination of a shallow and deeply laid foundation is used.

In areas with a slight slope (no higher than 10 - 20 cm), the plane is considered conditionally horizontal. The deepening level is assumed to be general along the entire length, taking into account the vegetation layer.Sometimes they cut off part of the hill or fill it up.

On slopes of medium steepness (more than 20 cm), development begins from the bottom point, the rest of the perimeter is arranged at the level of the accepted top of the tape support. For backfilling, a non-porous soil is used.

On steep slopes (more than 1 meter), piles are placed or each stepped foundation is calculated and poured individually according to the drawing. The construction site is divided into parts, while the difference between the ledges should not be more than 0.5 m.

Required tools and materials

Tools and materials are procured in advance to avoid work stoppages. The standard set can be supplemented with different foundation options.

List of materials for formwork and step casting:

- cement of grades M 450 and M 500;

- fine sand;

- medium-sized crushed stone;

- wooden beams (50 x 75 and 75 x 100 mm), slats (25 x 50 mm) and boards (20 - 25 mm);

- reinforcement for the frame, the diameter is taken in accordance with the calculation.

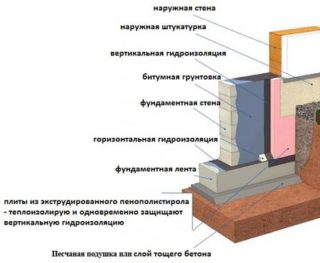

The rods are connected in nets with knitting wire or welding. For the second option, an apparatus is required. The stepped strip foundation is isolated from moisture using roofing material. Insulation is necessary so that the cold is not transferred to the walls.

Tools for work:

- hacksaw, jigsaw or chainsaw;

- hammer, screwdriver;

- marking cord, square, tape measure, level, plumb line;

- buckets, shovels, stretchers.

If the concrete is prepared by hand, a trough must be prepared for mixing the mixture. More often they take a concrete mixer, which significantly reduces labor costs and increases the speed of pouring.

Installation work

Before drawing up the project, they make a geodetic survey and determine the composition of the soil. An effective drainage system prevents the ground layers from collapsing and sliding.

Further work is carried out with the implementation of step-by-step instructions:

- mechanically strengthen the soil by arranging a bulk weight - denser soil masses to prevent slipping;

- put the formwork in compliance with the design differences, taking into account the need for one level of the horizontal for the construction of walls;

- reinforcement is used according to the drawing, grids and frame elements are boiled in the formwork or on the ground, and then additionally connected;

- waterproofing is fixed on the inner walls, and insulation is done after the concrete has hardened and the formwork has been removed.

The concrete is fed continuously to reduce the number of technological breaks. It is not allowed to connect the previous and next stage of pouring at the junction of two sections of different heights.