A compacted gasket between the support of the house and the subgrade is arranged to reduce the settlement of the structure. Foundation pillows under the house are made of different materials, they are bulk and prefabricated. The type of bedding depends on the mass of the building and the properties of the soil; sand, crushed stone, concrete and gravel are more often used, which do not lose quality when moistened, freezing.

The need for a foundation cushion

The soil under the foot of the foundation sags after the start of economic activity in the building or when it gets wet, thawed and frozen. As a result, there is an absolute or average settlement of the structure, caused by a change in the structure of the soil.

Damage to foundations is in the form of distortions, rolls, shifts and twists. Backfill helps the structure of walls and ceilings to be operated in the designed position. The house will not collapse, no cracks will appear on the facade of the building.

The backfill is arranged to compact the soil under the foundation and reduce future deformations. The layer helps the rhythmic distribution of forces on the base, reduces the rise of soil moisture at the capillary level.

Foundation cushion device

If the weight of the house is small and a frame type with wooden floor beams is being built, the bedding device can be neglected in the case of stable soils or a layer of minimum thickness can be made. A sand cushion for a tape-type foundation is made layer by layer, followed by compaction of all layers.

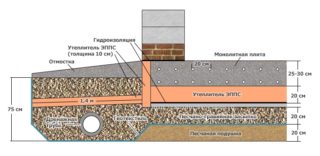

Rules for arranging bedding under a monolithic reinforced concrete foundation or slab:

- before tamping, crushed stone or sand is spilled with water so that the elements of the material settle under the influence of gravity;

- the pillow is made under the entire sole of the support, while it should be at least 0.3 meters wider than the tape;

- use refined materials.

Attention is paid to the quality of materials, for example, clay impurities in the sand will lead to swelling of the layer when moistened and further freezing. Dusty and fine sands will work in the same way, so you should not use them for bedding, but rather take material of a coarse fraction.

Geotextiles are often used - a fabric or non-woven fabric made of polyester or polypropylene. The fabric is placed on the ground in front of the sand layer so that the particles of the material are not washed into the ground and the layer does not swell.

Varieties of pillows

Backfills and tapes FL of reinforced concrete belong to the technically correct methods for arranging artificial substrates for foundations. In difficult cases, gaskets made of stone elements are used, for example, when erecting hydraulic structures.

In the conditions of private and industrial construction, the following types of materials are used:

- coarse rocks (crushed stone, gravel);

- sand;

- monolithic or precast concrete.

A variety is chosen taking into account the number of storeys, the budget of the building, the type of soil, the level of soil moisture and the level of freezing. Sand and crushed stone is available in all regions, these materials reduce heat transfer into the ground and form a solid and reliable foundation.

If the groundwater has a high pressure, there is a danger of floating up the building supports, therefore, the earth under the sole is artificially made heavier with a concrete layer. Use ready-made FL foundations from factory blocks or pour a monolith.

From sand

Such a base is used for houses whose height does not exceed 1 floor.For effective soil compaction, material with a grain size of 1 - 2 mm is taken, river species or washed from quarries work better.

Advantages of a sandy substrate:

- good thermal insulation from the cold;

- the possibility of thorough sealing;

- availability and low cost.

If the moisture level rises high, then put on artificial fabric. Sometimes heaving layers are removed completely and replaced with sand. The thickness of the interlayer is chosen individually, more often it is taken by calculation. The sand is laid in layers, each is rammed, while the intermediate thickness of the layer is greater with mechanical compaction than with the manual method.

Sand is formed during the destruction of rocks of great strength and is a loose mixture of grains of quartz mineral. River rocks are characterized by round, rounded particle shapes.

From rubble

Crushed stone is obtained by crushing rocks, boulders and gravel, the material is distinguished by a large weight (1.8 - 2.8 t / m3). The substrate for the support of the house is strong and stable after tamping. Such layers can be easily stacked on their own. Crushed stone bedding requires a coarse sand layer prior to laying.

The grain size of 20 - 40 mm is most suitable for the reinforcing layer. A crushed stone pillow for the foundation is used under low-rise buildings made of stone and brick with reinforced concrete ceilings and coatings.

The thickness of the layer is chosen so that the top mark coincides with the level of the base of the foundation support under the structure. The top of the bedding is leveled and adjusted with a level. This is done to maintain the design height of the foundation and not reduce it. If the top of the crushed stone is below the required mark, then there will be an overconsumption of concrete on a monolithic tape.

Concrete

The concrete base is the most durable, but its cost exceeds the previous varieties. The pillow for FBS blocks is made monolithic or prefabricated. Pillow blocks are made of trapezoidal or rectangular cross-section.

Their parameters:

- height 300 - 500 mm;

- length 800 - 2800 mm.

Blocks are laid on the ground if the soil belongs to the category of sandy bases, or a sand layer with a thickness of 100 - 170 mm is made under them. The elements are placed in a continuous tape or placed at intervals in which sand is laid.

In both cases, overlapping of the seams with a subsequent layer of foundation blocks is required. There are ribbed, hollow versions of prefabricated pillows, but they are not widely used. The dimensions of the FL blocks are taken according to the design standard sizes and according to the calculation in the project.

Monolithic gaskets are a strip of concrete, which is arranged using formwork and reinforced with a metal mesh throughout. This option is placed under heavily loaded structures and is used for unstable soils. The width of the base exceeds the transverse dimension of the foundation by 30 cm.

Interlayer thickness

The height of the cushion is always taken after the design calculation. For this, experts make geological surveys of the soil in the region of construction and find the characteristics of the soil. At the level of the sole, the average ground pressure is perceived, therefore, due to the compaction, this force will be less. The load will be absorbed by the natural base, therefore, the correct choice of layer thickness will prevent the possibility of deformation.

Recommended layer thicknesses:

- sandy base - 15 - 60 cm;

- crushed stone bedding - 20 - 70 cm:

- concrete monolith - 25 - 50 cm;

- prefabricated elements - 30 - 50 cm.

The thickness of the interlayer can be reduced by using a geotextile fabric, which will exclude the ingress of moisture to the base. The combination of pillow materials also contributes to the reduction in size.

Application area

Application features:

- The crushed stone layer is used in housing and economic construction of multi-storey buildings from various materials. A reliable compaction works flawlessly while adhering to the technology of filling and ramming.

- A sand cushion is placed in areas where there is no water or drainage is made. It is used for one-story buildings, since the sand does not have a high bearing capacity.

- Concrete is a durable material, therefore it is used in various conditions.

They make a foundation plan, where they mark the location of the foundation bed, indicating the depth, marks and dimensions of the foundation pad.

How to make a pillow under the foundation

They dig a trench, then clean and level the bottom of the pit. Next, the geotextile is laid so that the left side edges cover the rammed pillow from above.

Next, do in order:

- coarse sand is poured, each layer is moistened and tamped manually or mechanically;

- medium-sized crushed stone is poured with a project layer and rammed manually or using vibratory rammers;

- sand 20 cm high is poured on top of the crushed stone, then spilled with water from a hose so that the particles wake up and compact the stone layer;

- the free ends of the geofabric are brought to the surface of the pillow.

If the dimensions of the finished prefabricated pillow blocks do not coincide in length with the foundation elements, the retaining elements are placed with a small gap.

I have not seen more nonsense about pillows - its main purpose is leveling the base and not talking about the depth of freezing, the types of soil under the foundation, the level of the groundwater and its possible movement in the level and under the foundation and much more, and these are the legs of the structure and the cracks in the walls, slopes of the entire building to the south, waterlogging of foundations and freezing of the massif in winter with premature destruction of the foundation itself. In general, this whole scientific knowledge in many areas of different sciences is like the foundation of the Ostankino tower. The greatest difficulty is given by clays, then there are silty sands, and so on.

As you put 60 cm of sand, the house will crack. Since my youth, I remember that no more than 15 cm and then only for leveling the base.

There is SNiP, everything is described there, so you don't have to be smart with fabrications.

You write everything correctly! I always said that myself. My house on 2 floors in a former swamp has been worth 10 years, and some smart guys built a garage for a neighbor (they dug 130cm, then covered 60cm with sand). He said to his neighbor, he says - they know better. As a result, the next year he pulled the walls together with corners so as not to fall apart))).

And as a basement, if needed, what kind of foundation to do, tape or also some kind of bells and whistles.

My father built a house 65 years ago without any foundation, it still stands and my mother lives in it. The house is wooden. And now there are some troubles, and the houses are falling.

The house can be built without a foundation up to 3 floors ,,,,,