Geotextile is a woven fabric made of synthetic threads or made by thermal bonding or needle punching. The material prevents the erosion of the sand bed by ground fluids, silting of the pit with clay deposits. Geotextiles for foundations are indispensable in swampy soils during the construction of massive structures.

- Functions and characteristics of foundation geotextiles

- Is geotextile water permeable

- Varieties of geotextiles

- By composition

- By structure

- Rules for choosing geotextiles for the foundation

- Possibility of replacing geotextiles

- What can be replaced

- The use of geotextiles for different types of foundations

- Monolithic tape

- Precast Concrete Belt

- Pile foundation

- Slab foundation

- Blind area

- Popular types of domestic materials

Functions and characteristics of foundation geotextiles

At the base, polyester, polyamide, fiberglass or polypropylene threads are used; in mixed versions, cotton or semi-woolen fibers, viscose are attached. They are used in different areas of management, in construction, crushed stone is laid on geotextiles or sand, foundations are wrapped.

High-quality polypropylene material is placed in the soil during the construction of runways, railways and roadways, laid under the blind area and layers of paving slabs.

Is geotextile water permeable

In general, such a canvas is hygroscopic, but each type conducts moisture in a different way. To determine the flow rate, the volume of water passing through at a given time at a specific pressure is measured.

Permeability depends on characteristics:

- the type of textiles (needle-punched passes more than thermally bonded);

- particle size and pore diameter;

- density of the canvas;

- surface structure (smooth or rough).

The way of laying geotextiles affects the throughput properties. Some species collect a mass of water along the surface, while others conduct moisture in only one direction.

Varieties of geotextiles

In construction they use:

- non-woven needle-punched material;

- needle-punched nonwoven fabric with heat set on one side;

- needle-punched nonwoven film with double thermosetting.

Gasket insulation is produced on high-quality equipment, each batch is supplied with technical data sheets and quality certificates.

By composition

Polyester yarns are obtained from recycled waste, then short fibers are held together in dense layers. The particles are short, so the surface is bristled.

Polypropylene textiles are produced from primary raw materials in the form of long continuous cords, therefore, a durable geotextile under the foundation is formed.

The color is brown, beige, black, but white is considered the standard. When wet, polypropylene does not separate into layers, has a dense structure and a smooth surface.

By structure

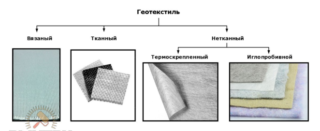

In woven types, the lines of the warp and weft are intertwined, while the density is controlled by the size of the gaps between the threads. The structure provides high tensile strength, so high-density woven materials are used to reinforce embankments and airfield elements. Woven loose types are used under blind areas, to strengthen the soil of shallow foundations.

Non-woven types are made by thermal or mechanical bonding of polymer fibers. In this category, a distinction is made between thermally bonded and needle punched material.

Rules for choosing geotextiles for the foundation

The insulating sheet is used in many areas, but special selection criteria are applied for construction. The separating layer of geotextile under the foundation slab must have high mechanical and physical properties.

To choose, take into account the qualities:

- versatility of application;

- density;

- affordable price;

- environmental friendliness;

- durability;

- strength.

The widespread use of geotextiles is explained by simple installation, which is easily performed by people without special qualifications. The blade weighs a little and is cut with scissors.

Possibility of replacing geotextiles

The canvas performs special functions that are difficult to reproduce with other material. In exceptional cases, builders are advised to use gaskets similar in properties, but the quality of protection from this may suffer.

What can be replaced

If it is not possible to purchase and install geotextiles, builders use roofing material. This insulator keeps the pillow from getting wet, but has a shorter service life (20 years versus 80 years for geotextiles).

Sometimes they put a small-sized mesh made of galvanized or metal. Such layers partially function as geotextiles. Dornit is considered an analog material, which is a kind of geotextile material.

The use of geotextiles for different types of foundations

The insulator is produced in rolls with a width of 2 to 6.5 meters and a length of 30 to 130 meters. Unit dimensions are determined depending on the scale of work.

The density is chosen according to the type of construction:

- for private housing construction, geotextiles with an indicator of 200 - 300g / m² are needed;

- unstable soils are drained with 300 g / m² material;

- simple landscaping works - 100 - 200 g / m².

When arranging the foundation, material with a density of 150 - 400 g / m² is taken, the value depends on the type of foundation and the quality of the soil.

Monolithic tape

The fabric is laid at the bottom of the trench to protect the layer of sand and gravel from getting wet. The edges of the geofabric are wrapped on a pillow with a slight overlap. The material is placed inside the formwork so that after pouring it is on the outside of the tape strip and protects it from moisture.

Install according to the instructions so as not to confuse the sides during installation. A thermally bonded form with a density of 200 - 250 g / m² is used. The denser type costs more, but the result is the same.

Precast Concrete Belt

The use of geotextiles in the construction of prefabricated foundations differs in that the insulation is glued to reinforced concrete blocks using molten bitumen or special mastic.

The seams are treated with glue, and the edges are taken out of bounds, and after installation, they are wrapped up. A seamless installation must be ensured. Use a material with a density of 250 g / m², produced by a heat-pressed method.

Pile foundation

In the pile foundation, geotextile is placed in the case of the construction of a basement floor. At the end of the driving of the uprights, the upper soil layer is cut off and the web layer is laid. A sandy and crushed stone layer is placed on it under a cement mortar.

The material prevents soil swelling and ground movement. The canvas excludes wetting of the basement and moistening of the walls of the house, for which geotextiles with a density of 100 - 200 g / m² are needed.

Slab foundation

It is equally important to use geotextiles for a monolithic foundation slab. In this case, the bottom of the excavated pit is covered with insulation over the entire area. Choose a fabric with a density of 350 g / m². Put the canvas on the surface again after the device and compaction of the underlying cushion, take the indicator 200 - 250 kg / m².

For reliable protection of the slab foundation, polymer varieties of thermopressed textiles are used to protect the concrete monolithic slab from the effects of soil and rainwater.

Blind area

The blind area protects the foundation from rain and melt water, but is open and interacts with groundwater. Its destruction is prevented by making a waterproofing lining, for which geotextiles are placed under a concrete strip.

The insulation is laid along the base of the open pit so that the outer ends can be wrapped around the sub-base. The blind area often falls through, because a large amount of water flows down from the roof and moisturizes it. A separating layer with a density of 150 - 200 g / m² will protect the strip from vertical shifts.

Popular types of domestic materials

Polimerholding Group of Companies launches the Dornit line. All geotextiles used in construction are called the popular brand name. The company produces non-woven and woven varieties for home and garden.

Geotext Group LLC produces geomaterials for individual construction and road works. Large-scale production provides thermopressed types for drainage, ponds, sports complexes.

LLC "Nomatex" manufactures high-quality textiles for mass use and for individual orders with a density of up to 800 g / m². Rolls up to 5 m wide are used for seamless coating over a large area.

LLC "Avantex" produces a needle-punched category, the density of the material is 100 - 600 g / m², and the width of the roll is increased to 6.3 m. The raw materials are primary products and secondary waste in the form of polypropylene and polyester.