The lower part of the building is most susceptible to aggressive environmental influences. The artificial stone for the basement protects the walls and gives the house a unique look. Knowledge of the types of finishes, its characteristics and installation methods will help you choose the right material.

Finishing requirements

The basement of the building is in contact with the adjacent soil, is affected by precipitation, and is accessible to external influences.

There are a number of requirements for wall decoration that must ensure:

- Waterproofing. Moisture enters the basement along with precipitation, flows down from the roof. The task of the artificial stone is to prevent moisture from penetrating onto the load-bearing walls, which are actively destroyed by it.

- Resistant to climatic conditions. In the autumn-winter period, sharp temperature changes are often observed - poor-quality finishing quickly loses its attractive appearance, loses its protective properties.

- Mechanical strength. The height of the plinth is accessible for damage by a person or objects when they are moved.

- Durability. Such a finish is not the cheapest material, and replacement will require significant costs.

- Attractive appearance. The stone for facing the basement is selected taking into account the architectural features of the house, the materials should be combined stylistically.

- Fire resistance.

The range of products from leading manufacturers allows you to choose a product that meets all the requirements.

Material advantages

When choosing a facing stone for a plinth, they pay attention to functionality, manufacturability and material cost.

Among the positive aspects are:

- small weight, which simplifies and reduces the cost of loading and unloading operations and transportation to the place of work;

- manufacturability - self-assembly does not require the skills of a bricklayer or tiler;

- simplicity and ease of processing - cutting and sizing is performed using a household hand or electric tool;

- standardized dimensions that allow you to accurately calculate the required amount of material;

- low load on the base due to its low weight;

- a wide variety of materials from which the artificial stone is made, colors and textures;

- durability and resistance to weather conditions.

Disadvantages are noted only by owners who are in favor of environmental friendliness of houses, since some types of materials are made using chemical components.

Varieties of artificial stone, their features

The basement stone is produced from materials that are completely different in composition, structure and properties. The choice is made by comparing all the qualities of finishing and skills in one type of installation or another.

An important factor is the method of fastening, which can also greatly affect the cost of the finished coating.

Clinker tiles

The stone for finishing the basement of the house in the form of clinker tiles is obtained from special types of refractory slate clay.

The production process consists in extruding a mixture of clay, quartz sand, broken faience and chamotte to give the desired product the desired shape.To add color, oxides of various metals are added to the composition. After that, the finished tiles are baked at a high temperature.

In terms of consumer properties it is similar to natural stone:

- resistant to temperature changes;

- practically does not absorb moisture;

- does not fade in the sun;

- difficult to damage mechanically.

Depending on the shape, the clinker is given a different texture.

Disadvantages of clinker tiles: high price, laborious installation.

Installation will require the skills of a tiler. A large number of seams will require an increased consumption of assembly glue.

Concrete stone

Artificial stone for finishing the basement is made from a concrete mixture, the basis of which is cement and quartz sand. For the convenience of work, plasticizers are added to the mixture - substances that increase the fluidity and plasticity of concrete, increasing the strength of the product. Dyes give the stone the desired color.

For large-sized "stones", reinforcement with steel or fiberglass rods is provided.

The production technology includes several procedures:

- A polyurethane or silicone mold is treated with a release agent (lithol, emulsol, talc), which prevents the concrete from sticking in the mold.

- Mix a solution of cement and sand in a ratio of 3: 1, add from 2 to 6% pigment dyes and 1% plasticizer.

- Pour half the volume with a mixture, which is leveled with a spatula.

- Reinforcing mesh is laid.

- Completely fill the mold with concrete.

- The casting composition is upset on the vibrating table.

- After hardening, the molds are released and the drying of the stones is continued.

The advantages of artificial concrete stones include mechanical strength, resistance to climatic conditions, long service life, and a relatively low price.

The mass of the material does not allow installation solely on cement mortar or glue. The installation of anchors will be required, which complicates and makes installation work more expensive.

Other types of injection molded products

In addition to concrete, the following are used for the production of artificial stone:

- Acrylic resin with mineral filler. As a filler, granite, quartz, marble chips, sometimes fine gravel are used.

- Gelcoat and microcalcite for obtaining a base of liquid stone and gelcoat with a hardener for the face layer.

Facing the plinth with an artificial stone made of these materials is distinguished by an increased price with the same characteristics as the concrete version.

The pluses include a decorative appearance.

For decoration of external walls, it is not recommended to use gypsum products that are subject to accelerated destruction in conditions of high humidity and temperature extremes.

Flexible stone

The material is made in the factory shop or directly in the quarry.

The product consists of three layers:

- base made of fiberglass, PVC plastisol, bitumen or fabric;

- the front side is made of fine sand or thin plates of natural stone;

- the middle bonding layer connects the base and the front.

In the factory, a cheap version is produced with sand or a fine fraction of stone as a front finish.

In quarries, rock layers are cut into plates up to 3 mm thick and glued to the base. Such material is less flexible, as the plates can hit the corner of the house or turns - careful fitting will be required.

Finished products are distinguished by the type of rock, base material, adhesive composition, color and texture. Facade flexible stone is produced in the form of plates with dimensions from 500x250 to 1000x2500 mm. The thickness depends on the top layer and can be from 2 to 6 mm.

With a pattern that does not repeat, the material is released in rolls.

A flexible stone is attached to a special glue applied to the surface of the wall, which is pre-leveled. The joints are sealed with water-repellent compounds.The result is a seamless coating that is resistant to climatic conditions and mechanical stress.

The advantages of the material include:

- the ability to finish uneven surfaces with any bends;

- light weight;

- heat resistance;

- ease of installation;

- ease of hiding the unevenness of the wall surface.

Stone from polymer sand mixture

The material is made from sand, bonded with a polymer base.

A separate material is produced in the form of tiles, for the connection of which a lock connection is provided in the form of grooves and ridges.

A crate is mounted on the base. Using self-tapping screws, the plates are attached to the frame.

By combining polymer-sand tiles and a foam base, a modern finishing material with the function of insulation is obtained. The gluing is carried out in the factory under the presses, which makes the product a single whole. This option is attached to cement-based adhesives.

Tile advantages:

- light weight;

- the possibility of self-assembly;

- ease of processing - cutting and fitting is possible with a hand tool;

- resistance to weathering;

- durability.

Polymer sandy tiles are produced in various colors and textures; they can be selected to match any wall decoration.

Installation methods

Depending on the selected material, three methods of attaching an artificial stone to the wall are used:

- On a pre-assembled crate. The method is suitable for polymer sand tiles.

- Wall mounting with glue or cement composition is used for finishing with clinker tiles, flexible stone and cast products from concrete and polymers.

- Fastening the stone directly to the wall using self-tapping screws. The surface must be pre-leveled as carefully as possible.

Stages of installation on the frame

As a frame lag, wooden bars or a galvanized metal profile are used. In the first case, the tree must be treated with an antiseptic and fire retardant composition.

Before installing the battens, the basement surface is cleaned of dirt and impregnated with a water-repellent primer. Further, the installation takes place according to the principle of a ventilated facade without or with insulation.

The order of layers using insulation starting from the wall:

- Vapor barrier membrane reinforced with nail dowels.

- Lathing, which additionally secures the vapor barrier.

- A layer of heat insulator made of polystyrene or polystyrene foam.

- Waterproofing material.

- Polymer sand tiles.

It is important to observe the exact fit of the individual sheets in order to exclude places for moisture to penetrate the walls.

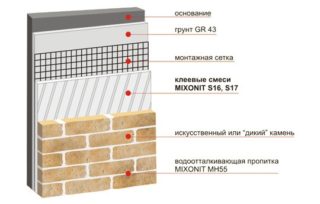

Installation on adhesives

Usually, the manufacturer recommends which brand of adhesive the artificial stone is designed for. It all depends on the weight of the cladding and the conditions for further use. It is permissible to mount concrete products on a cement-sand mortar.

Work algorithm:

- They knock down the influx of cement mortar, scrape off greasy and oil stains from the walls of the basement.

- They are treated with a deep penetration primer.

- The surface is leveled with putty or plaster, leaving irregularities of a maximum of 20 mm per running meter.

- Dilute the adhesive composition recommended by the manufacturer or a cement-sand mixture.

- Glue is applied to the surface of the artificial stone.

- Glue the finishing material to the wall.

- Wait the required time before setting the solution.

- Seams are sealed to exclude moisture penetration.

- Remove glue residues that spoil the appearance.

- After hardening, remove the protective film from the front side of the finishing material.

It is necessary to protect the surface from precipitation for the period of complete setting of the solution.

Artificial stone is a durable and reliable material, perfect for decorating basement walls in residential and public buildings. The structure and characteristics of the coating reliably protect buildings from the influence of climatic factors and accidental damage.Having assessed their capabilities and skills, many developers independently carry out construction work, saving significant funds on contractors' wages.