Structurally, the basement is one of the most important elements of any home. With its help, the foundation is separated from the walls of the first floor, thereby protecting the building from the penetration of cold and moisture. For this, the surface of the connection of the walls of the building with the plinth is additionally protected with heat and waterproofing materials. A properly made base / plinth will ensure the durability of the building and give it a certain originality.

Plinth classification

Serious tasks are assigned to the basement belt, ensuring the smooth operation of the building and the comfort of staying in it for residents. Therefore, before building a basement around the house, the developer needs to familiarize himself with the existing structures and their main characteristics.

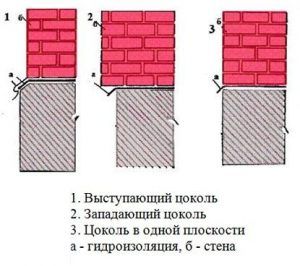

The following types of basement are suitable for private housing construction:

- flush with the wall;

- falling;

- speaker.

A protruding basement is erected when an insulated basement or a recessed garage is provided in the building project. At the same time, due to the thick external walls protruding beyond the common facade line, heat is well retained in the house. However, such a design will require you to equip a reliable waterproofing and install drains around the entire perimeter of the building.

A plinth, the outer surface of which is in the same plane with the outer walls of the building, is rarely erected. The reason is that the waterproofing is not protected from external atmospheric influences and is visible on the surface of the outer walls. Without additional cladding of these surfaces with finishing boards, the appearance of the building leaves much to be desired.

Design features and materials for the construction of the basement

Structurally, the structure of the basement belt is determined by the type of foundation base and depends on the materials that were used in its construction. On a strip foundation, the structure of the basement belt can be:

- monolithic, poured with concrete together with the foundation;

- from concrete foundation slabs laid on top of the base;

- in the form of a solid red brick wall, erected on the surface of the foundation.

If the building will be erected on a pile / column foundation, the basement can be:

- hinged - for the structure, you will first need to install a metal frame (frame) on which sheet insulation and facing material will be attached;

- in the form of a shallow strip base with brickwork laid along the perimeter of the entire house;

- in the form of a wall (pick-up) between the piles (pillars), which will cover the subfloor of the house.

The base-cap is the simplest type of basement belt, which is arranged between the foundation pillars. In this case, the height of the wall should be at least 0.5 m. As a rule, it is erected from the same material as the pillars (brick, wood, concrete, etc.), and then plastered with mortar. Making such a basement with your own hands will not be difficult even for an inexperienced developer.

As a rule, the filling is buried in the ground by about 25-50 cm. At the same time, there will be no extra sand cushion with a depth of at least 15 cm. Wooden parts that will be buried in the ground must be tarred - this will prevent them from rotting.

The thickness of the filling is determined based on the material used. For reinforced concrete, it is 10-12 cm, for rubble masonry - at least 10 cm. The brickwork must have a thickness of at least half a brick.

When the house is built on heaving soils using a columnar foundation, the support surface for the base of the basement is:

reinforced concrete grillage - for houses made of bricks or small blocks;

wooden strapping from a bar and logs - for wooden houses.

When arranging a monolithic base, you cannot lean it directly on heaving soil. 10-15 cm of free space is left between the ground and the basement, which is then filled with non-porous soil or hidden behind decorative trim.

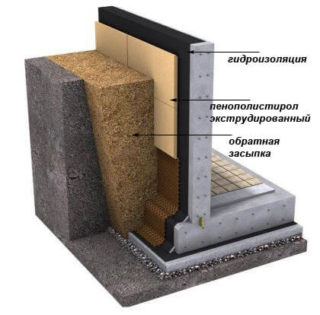

Insulation and waterproofing of the basement

The basement belt is one of the most vulnerable elements of a building under construction. It is entrusted with the functions of protecting the house from the effects of moisture and cold, therefore, special attention is paid to the issues of waterproofing and insulation.

Waterproofing

For waterproofing the basement, roll and coating materials are used. The main advantage of rolls is their low price and quick installation. Moreover, they are short-lived and easily amenable to mechanical stress. These materials cannot be used in places where communications are adjacent.

There are two types of roll-on waterproofing:

- pasting - when laying on the surface of the foundation, it first requires the application of bitumen mastic to the monolith, and then it is pressed and smoothed;

- weldable - is a canvas made of polyester or fiberglass with a layer of special mastic.

Before installing the pasting and overlay materials, the surfaces of the foundation and the basement must be thoroughly cleaned of dust and dirt.

Of the coating materials, special mastics (bituminous, polymer and their combinations), cement coatings and binding plasters are most often used. All these materials are applied to foundation and basement surfaces with a brush or roller. Fiberglass, which reinforces the first layer of applied mastic, gives them increased strength. Lubricating coatings are also short-lived and require additional protection against mechanical damage.

For waterproofing a basement made of brick, bitumen grease and roofing material are traditionally also used. Using a bitumen grease, which must be applied in several layers, it is necessary to strictly maintain the temperature regime. If it overheats, the waterproofing coating will be of poor quality. It is necessary to cover the surface of a brick base with roofing material with it in at least 4-5 layers.

Injectable and penetrating compounds, which have recently begun to be used in construction, are free from all of the above disadvantages.

- A composition is applied to wet concrete, which, having reacted with water, turns into crystals that penetrate into the pores of the base to a depth of 25 cm. In this case, the concrete becomes waterproof.

- Liquid for injection penetration is injected into all pores and cracks of the foundation and basement, made of concrete, rubble stones and bricks. This process is quite expensive and highly labor-intensive; it requires the involvement of experienced craftsmen.

When using solid red brick for laying the basement belt, external waterproofing work is not required - a waterproofing layer is applied to its surface during the manufacturing process.

Warming

For insulation of the basement belt, extruded polystyrene foam is most often used. It is characterized by high characteristics of strength, moisture, frost and acid resistance.It is produced in the form of plates with a thickness of 3 to 10 cm. These plates are glued to the surface of the basement with an adhesive solution and then reinforced with special dowels.

A significant disadvantage of this material is its flammability. After the installation is completed, the surface of the base must be treated with a non-combustible material.

External finishing

Upon completion of the waterproofing and insulation of the basement, they proceed to the external finishing work. Used as finishing materials:

- porcelain stoneware tiles;

- artificial or natural stones;

- basement siding;

- corrugated board;

- decorative plaster, etc.

Facing the basement belt of a country house, in addition to the decorating effect, performs the function of protecting the entire building from the effects of various negative factors (atmospheric, mechanical, etc.). The choice of finishing materials must be approached responsibly, without shifting this responsibility onto irresponsible hired workers.