The buildings erected on a high-quality foundation are distinguished not only by their reliability and durability, but also by their high time consumption, solid labor intensity and high cost. This is especially true for structures built on slab or strip foundations. In industry and in the construction of multi-storey buildings, these issues are partially solved through the use of driven supports, which for a long time are inaccessible to individual developers. However, pile driving - a technology that has a number of advantages over traditional methods of building foundations - eventually spread to private houses.

How to drive piles correctly

The pile foundation is equipped where there is a high possibility of deformation or destruction of the building in the presence of cyclic freezing / thawing of the soil. To avoid the negative consequences of these processes, the piles must be driven to a depth that exceeds the level of soil freezing. In addition, when driving piles, it is necessary to punch through soft soils and achieve a solid foundation.

When hammering a support to a shallow depth, you need to be sure that it does not rest against a stone. Indeed, during the construction of the building, the load on the piles will increase and they will gradually sink into the soil a little deeper. At the same time, the pile on the stone will not be able to plunge lower, which will cause a skew of the foundation and the entire structure.

Advantages and disadvantages of driven piles

The technology of laying foundation foundations with the help of driven piles is increasingly used in the construction of private residential buildings and in the arrangement of buildings for household purposes. This is due to the advantages characteristic only of this type of foundations:

- versatility;

- prompt installation - a full-fledged base can be prepared in 1-2 days;

- the minimum volume of earthworks, which reduces the consumption of the building mixture by 20-30%;

- carrying out work at any time of the year:

- high load-bearing capacity, resistance to deformation and durability of the base of the house.

Pile foundations are erected in any climatic conditions and on any soil. The relief of the area where construction work is supposed to be carried out does not matter either.

If, when laying an ordinary concrete base, the laying of walls begins only after 20-25 days, then when arranging the pile foundation, construction work can be started immediately.

Disadvantages inherent in pile foundations:

- The need for thorough geological exploration of the area allocated for construction. Mistakes made during survey work may further result in deformation of the foundation.

- Requirements regarding the distances to nearby buildings.

- The need to use highly specialized technology. In some cases, it is allowed to drive piles with a hand hammer.

In a house built on a pile foundation, it is not possible to equip a basement and / or basement floor.

Types of piles and methods of driving them

Piles, on the basis of which foundations are erected, are considered the most reliable support. They securely fix the foundations of private and multi-storey buildings in a wide variety of soils. In construction, piles made of different materials are used, and they are immersed in the ground in different ways.

There are 4 types of driven piles:

- reinforced concrete;

- metal;

- wooden;

- bored (bore injection).

Metal piles are made both industrially and at home. This is facilitated by their simple design (pipe, tip, head), as well as the high versatility of metal, which is stronger than wood and more technologically advanced than concrete.

Reinforced concrete piles are a reinforcement cage filled with concrete. They can be of various shapes (round, square, etc.). The lower end of the support is formed in the form of a tip, and the upper one is designed so that, before hammering, a special head made of strong steel can be put on it, which protects the pile from destruction when hit by a hammer.

Wooden piles up to 40 cm in diameter are made of hard wood (oak, cedar, etc.). The deepened end of such a support is equipped with a metal tip, and the upper part is protected from cracking with a special metal hoop. If a pile foundation of special strength is required, "packages" are used - a bundle of several piles, which are driven into the ground as a whole.

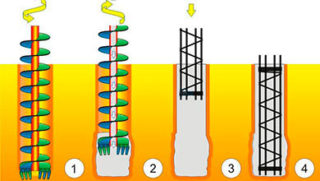

Bored piles are structures made directly when laying the foundation. First, holes are made at the installation sites into which casing pipes filled with concrete mortar are inserted. To give such a pipe the necessary strength, it must be reinforced with a pre-prepared frame.

Driving methods

- The impact method is the most common technology for driving supports. Deepening is carried out using blows with a special hammer (headstock). To facilitate this process, there are special mechanisms and machines that have different power and other technical characteristics.

- The pilot drilling method is used to speed up the pile driving process. It is used when the soil at the construction site is too dense. This method is also suitable for laying a foundation in frozen soil. In the places where the supports are installed, wells are pre-drilled, the diameter of which is slightly less than the diameter of the piles. In this case, the depth of the wells should be 0.5 m less than the depth of the support. Then piles are driven into these wells.

If it is not possible to penetrate piles with a shock method (reconstruction of old buildings, construction work in areas with dense residential buildings or near houses in emergency condition, etc.), use less common methods, for example, the vibration or indentation method.

What piles are driven in

For the immersion of driven supports into the ground, the industry produces a wide variety of equipment. As a rule, such machines are assembled on the basis of bulldozers, truck cranes or excavators moving on a caterpillar or wheel drive.

The supports are driven into the ground using a pile driver. The principle of its operation is to apply a hammer blows to the end of the pile installed in the desired direction.

The impact mechanism is equipped with a hammer:

- working with the energy obtained from the combustion of diesel fuel;

- with a hydraulic drive, which provides lifting and lowering of the striking part of the hammer.

When erecting light household buildings, it is allowed to use a hand hammer, in which the striking part is manually raised to a certain height using a simple block-cable mechanism. Falling, due to the acceleration of free fall, it strikes the end of the support with force, gradually driving it into the ground. Such a pile driver can be equipped with a drum and the rope can be wound manually or by means of an electric motor.

There is a machine, the principle of which is to create vibration directed along the axis of the support - a vibrator.The vibrations are created by a special device that is fixed to the pile head. Structurally, it consists of a rotator and a weight with an offset center of gravity. Such a mechanism is driven by a hydraulic drive or an electric motor. At the same time, the generated vibration provides all the conditions for immersing the pile into the ground.

The builders have at their disposal a pile-pressing installation, with the help of which the support is smoothly pressed into the ground. In order for the pile to enter dense layers, the indentation process is completed by applying several blows to its head.