Leader drilling is widely used in the construction of pile foundations. This technology facilitates construction work in winter, as well as in cases when it is necessary to deal with high density soils.

Leader drilling technology for pile wells

Leader wells are specially designed recesses, into which reinforced concrete piles are later installed. The technology makes it possible to ensure a strict vertical position of the supports, which is difficult on solid ground. Drilling rigs are used to create wells. The diameter of the recess depends on how you plan to place the vertical support. If this is driving or indentation, to obtain the desired number, you need to measure the cross-section of the pile in the thickest place and subtract 5 centimeters from it. When vibrating, it is sufficient that the recess is 1-2 cm narrower than the diameter of the support. Sometimes on especially difficult soils, niches are made, equal in this parameter to the structure itself.

Advantages and disadvantages

When using leader drilling of wells for piles, the likelihood of violation of the integrity of the latter is reduced. Since the structures are underground, it is not easy to check them for damage, and the preparation of special holes for the supports helps to keep them in good condition. Other advantages of using drilling include:

- simplification of penetration of solid ground;

- facilitating the immersion of the vertical support into the finished recess;

- saving time for land work;

- reducing the resistance of the soil to the installation of piles;

- minimization of noise interference and vibration vibrations, which is especially important if other buildings are located near the foundation being built;

- the possibility of using on soils of various types;

- facilitation of vertical installation of supports.

The disadvantages of this technology are the need to rent special equipment and invite a team of workers. Before proceeding with the arrangement of wells, you need to calculate an estimate of all the costs that will go to the implementation of the foundation.

When planning the procedure, you will need to study the documents regulating the construction of foundations and land structures. This includes SP 45.13330.2017 and 45.13330.2012. Directly working with pile foundations is described in document 24.13330.2011. These standards regulate the drilling depth, operating conditions coefficients and a number of other issues related to well construction.

Why and when leader drilling is needed

The technology is used for installation of piles and sheet piles into the ground. It allows you to equip foundations of different configurations and dimensions. It is used in such situations:

- When building on solid ground. Dimple preparation eliminates the need to roll the pile through problem areas of the soil, which helps maintain soil integrity.

- When installing sheet pile fences.

- In regions with permafrost, where the soil is very dense, as well as when installing the foundation in the cold season.

- If there are many rocky areas at the site of the future foundation, as well as when working on rocky areas.

- In places where dense sandy areas were identified during the survey of the soil.Such layers cause difficulties when passing the piles without first creating niches for them.

Drilling will be useful not only on dense, but also on extremely loose soils. If the texture of the soil is fine, it will be more difficult to place the support in a clearly vertical position. Therefore, the well here performs a guiding function. The method is also recommended when the support elements are significantly deepened.

Manufacturing jobs

The depth of the niches to be created should be 90% of the vertical dimension of the piles to be placed. If the structures are not round, but polygonal, they are used instead of the diameter. The size of the screw used depends on the dimensions of the products. If the cross-sectional side of the pile is 0.3 meters, a value of 0.2-0.25 m is taken.With a diameter of 0.35-0.4 m, the idea is to use a screw stroke of 0.3-0.35 m. The well can be created by different methods : pick up the soil in whole or in parts with softening of the underlying layers. A collapsible auger can also be used. It must be remembered that the ground removed from the niche, covering the nearby areas, increases the level of the soil surface, which is guided by when creating a cavity. Therefore, it must be removed in a timely manner. Another option is to prepare a pit with the required reserve.

Instructions

At the end of the geological studies of the area, you can begin to prepare for the creation of depressions. Drill dimensions are selected taking into account the size and type of piles.

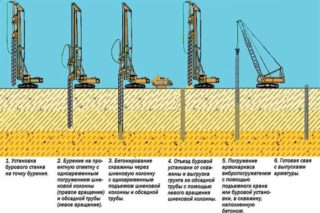

The sequence of installation work:

- Prepare the future site. It is not necessary to make it perfectly flat. It is necessary to remove the plants and the top layer rich in organic matter, and collect the debris. Consideration should be given to where the equipment for drilling gaps and installing support structures will be located.

- They mark the area. For maximum accuracy it is worth using a laser level. Other methods are also possible (for example, using a construction tape), but then it will take more time to achieve the rigor of measurements. In places where it is planned to create recesses, stakes are exposed.

- The equipment is placed in the designated areas and prepared for work. It is important to check the vertical level indicator.

- The actual drilling of the niches is carried out. When performing work, you need to focus on a pre-prepared project. It describes the sequence in which to create cavities and hammer supports. It must be strictly observed, otherwise there is a risk of damaging neighboring niches by vibration or shock. Usually all constructions are not done in one go. The depth of the wells must comply with building codes.

- When the niche is ready, a pile is mounted in it. You can do this by hitting a special hammer equipped with motors, or using a vibrating submer.

When the piles are installed, they are checked. The result should be considered by the employees of technical supervision. After that, you can proceed to further planned stages of construction work.

Leader drilling is well suited for piling on hard soils. It simplifies vertical positioning of the support and minimizes the likelihood of damage. Before work, you need to carefully study the building codes that govern them.