The lower strapping in the strip foundation is equipped to prevent deformation changes, subsidence, and a more even distribution of weight. It helps to avoid the destruction of the building.

General information about the bottom strapping

The strapping of the foundation of the frame house takes the loads from the wall structures and connects the latter into a single system with the floor and base. It creates a support that is convenient for the construction of the dwelling. If the grillage combines piles or pillars, then the strapping serves as a support for the walls. For a building to be reliable, both of these structures must be used. Strapping a frame house on a columnar foundation without a grillage is not the best option. This element alone is not able to efficiently cope with two tasks at the same time: combining parts of the base and supporting the walls.

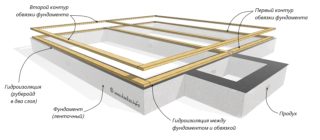

The strapping is organized not only for screw pile and other types of foundations with point supports, but also for strip structures and slabs. This is where material differences come to the fore. Two elements from similar raw materials can be combined more easily than from those of very different weight, density and performance properties (for example, concrete and wood). Therefore, the lower harness plays the role of a connecting element of the frame (floor and walls) with the foundation.

Construction Materials

To organize the strapping, a coniferous tree (pine, cedar, etc.) is used in the form of bonded boards, beams or solid logs. In most regions of Russia, these species are more affordable than deciduous ones. The choice of material should be based on the following criteria:

- low permeability to moisture;

- straightness;

- the possibility of long-term operation under high loads;

- as little susceptibility to rotting as possible.

In addition to the timber itself, a waterproofing layer will also be required. For this purpose, a simple roofing material is suitable. Mineral wool is used as a heat insulator. You will need parts for fasteners - ordinary and self-tapping nails with different sizes of the driven part (in the first case - 5.10 and 15 cm, in the second - 5 and 10).

Design options

The units of the material used for the strapping can be of different shapes. These can be logs, solid beams or boards composed of several layers.

Cohesive board

For strapping from boards, lumber, high-quality impregnated with an antiseptic composition, is suitable. If it was not possible to get such raw materials, you can take larch. Its resin has disinfecting properties. You should not save on the quality of the material - structures made of decaying wood quickly fall into disrepair.

For strapping, materials are used consisting of 3-4 boards fastened together with a section of 0.05 by 0.2 meters. They must be carefully sized for their dimensions; if possible, you should do it yourself. The use of non-planed raw materials is allowed. The boards are mounted by nailing or screwing them with fasteners in the manner of chess.

Beams

Solid bars can have dimensions of 0.15x0.15, 0.15x0.2 or 0.2x0.2 meters. The last two options are considered equivalent, respectively, to three and four bonded boards with dimensions of 0.05x0.2 m.If one of the sides of the bar is 0.2 m, it is placed on the head with the smaller side - then the structure will have a height of 0.2 m.

The raw materials used should not have a moisture content above 12%, foul or knotty. The bars must be chemically treated. For this, antifungal compounds, antiseptics, agents that prevent fire and moisture penetration are used. Since spruce wood has many knots, it is less suitable for work than cedar or pine.

You can connect adjacent elements in different ways. The "half-tree" method is popular: in this case, half-thickness grooves are cut in adjacent bars. Another method involves creating cutouts at a beveled angle so that no gaps are formed during fastening. A thorn-groove lock is also used. To make the cutouts more accurate, it is worth buying or renting a plane.

Log

Untreated logs are durable and carry the weights best. This material has the lowest cost, but the logs are difficult to install due to their irregular shape, which makes it difficult to fit, strengthen on the base and install the walls.

The manufacturing process of the bottom strapping of the strip foundation

Step-by-step sequence of work:

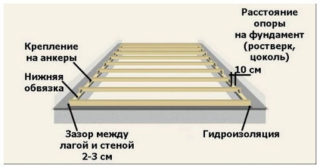

- Anchors or corks made of wood are mounted in the areas where the foundation is joined with the strapping. If 2 rows of boards are stacked, the fasteners must be larger.

- 2 layers of roofing material or other waterproofing material produced in rolls are laid and fixed on the base.

- They try on the boards to the foundation and drill holes in them for fasteners. Then they begin to fix the trim elements on the base.

- Corner strength is reinforced with additional fasteners.

- The horizontal alignment is checked. If there are differences, they are straightened with wedges and linings.

When using two layers of boards, first connect the upper one with the lower one by means of nails, and then, if necessary, align with larch wedges. To prevent the destruction of the latter, large cracks are sealed with a solution of cement and sand. The distance between the holes of the boards should not exceed 1.8 m. Each of the elements is secured with at least a pair of anchors.

Installing a log for a rough floor

- With a bar that serves as a support function for the end of the board. This will require additional attachment of the log to the strapping layer.

- With the use of corners or metal plates. Here the end of the board is well attached to the harness, but there is a deficiency of the lower support.

- The most reliable way is to mount it over the strapping. The latter in this case also serves as a supporting element. This method works well for a frame building that is being constructed in a platform manner.

The practice of combining the first and second paths - bars and metal parts. In this case, the joists and the strapping structure are connected quite tightly.

The lag step depends on the planned floor structure, the dimensions of the room and what load weight will press on the boards. The greater the distance between the walls, the smaller it is.For a two-meter room, the step will be 0.8 m, and for a three-meter room - 0.4 m (with a lag size of 5 by 15 cm; for a larger section, the step will be larger).

The bottom rail provides support for wall structures and simplifies subfloor installation. It is usually performed from a bar or sewn boards. The careful selection of lumber and their treatment with protective compounds play an important role.