For concreting the piles, shells with a drop-down or removable shoe are immersed in the ground. Casing pipes for bored piles are left in the ground or removed as they are filled with concrete. The technology has no restrictions depending on the density of the location of buildings in the city; in such conditions, the shells are buried by the screwing method.

Casing definition

The diameter of the bored rods is 0.35 - 1.5 meters, the length reaches 30 meters, this type of pile is used under high loads and with a deep location of stable soil layers.

The technology is used in the following conditions:

- concentrated horizontal and vertical loads;

- on construction sites with difficult engineering and geodetic conditions;

- in the case of nearby buildings.

Concrete pipes include several sections with special joints for a reliable and fast connection. Concrete is loaded into the funnel from an automobile mixer or an electric vibrating hopper with a pneumatic impact device is used. The used cocoon is taken out of the borehole after filling the specified height section with concrete.

The concrete in the wellbore is compacted with a vibrator, which is attached to the casing entry funnel. After full filling, the pile head is formed using an inventory machine and insulated in winter. Inclined and vertical elements are installed according to the technology of bored casings. Stationary capsules are immersed with a driteller (turntable), and the extracted sections are buried and removed using a vibratory pile driver.

Varieties of pile packing

Piles are arranged according to the principle of a wall in the ground. The trunk is dug with a hydraulic grab protected by a bentonite mixture. Concrete does not delaminate in concrete-cast collectors and does not mix with ground fluid that occurs in the passages during drilling. Concreting takes place evenly to the bottom of the well, with the cuttings coming out to the surface.

Popular methods of packing pile racks:

- drilling in inventory casing;

- percussion rope drilling;

- continuous hollow screw method;

- screwing the casing;

- vibration immersion of a hollow column;

- dredging under the protection of a clay mixture.

The widening at the bottom of the pile is done using the explosive method. In the finished well, the casing is mounted so that it does not reach the bottom of the passage by 1.2 - 1.5 meters. A charge of the required mass is lowered into the pipe, and the detonator is brought up to the demolition device. They explode after filling the shell with concrete, as a result of which the mixture enters the expanded lower sphere. The rest of the space is filled with concrete to the top.

Installation of bored piles using casing pipes

The inventory method is the use of casing capsules, buried in the process and removed after concreting.

There are types of installation:

- pneumatic rammed rods;

- vibro-rammed piles;

- frequency rammed racks.

Pneumatic tamping is used for bases with a high level of soil liquid standing. The mixture is fed into the casing capsule under air pressure in small fractions. The work is carried out through the pneumo-pressure sluice compartment with valves at the top and bottom for dosing.

Vibratory ramming is used in dry places. The casing body is immersed in the ground by vibration, which is equipped at the end with a removable ferro-concrete tip. The vibrator is removed, and the pipe is filled with a solution by 0.8 - 1.0 m and the tamper bar is lowered. As a result, the tip is pressed into the ground and a widened heel is obtained. The casing capsule is removed after filling with concrete.

Frequency ramming uses casing with a cast iron shoe at the bottom. A reinforcing cage is placed in the cavity of the column and immersed under hammer blows to the desired mark. When moving, the pipe compacts the soil layers. The casing is gradually lifted by vibration in parallel with the feed of the mixture, while the hammer continues to compact the concrete and the shoe is pressed into the ground at the bottom of the passage.

Purpose of casing in wells

The pipe keeps the earth from falling into the well, therefore, the wall material is chosen correctly. The selection depends on the diameter of the pile and the physical and mechanical characteristics of the soil. Often the material is plastic or metal. The device of bored piles with the use of casing pipes is used in any geological situation, unstable soils.

The upsetting is used in the following conditions:

- unexpected changes in the thickness of dense layers;

- when cutting mounds of embankments with boulders or remnants of concrete, stones inside;

- in the town.

Shells up to 10 meters are placed for medium and low loads (low-rise construction). Do not use the bored method in permafrost, when aggressive soil liquids are detected or industrial waste is exposed to the trunk in the ground.

Piles with packing up to 50 meters long are arranged in wet lands. Casing is placed in heterogeneous fluid soils interspersed with sandy loam and sandy layers. Casing piles up to 60 meters are mounted using powerful equipment on any soil. In seismic regions, the casing technology provides for metal shells that are not removed after being loaded with concrete.

Benefits of bored technology

The main positive point is the ratio of cost and reliability of the pile foundation. The foundation is a cheap and level support that can withstand up to 10 tons of pressure. Casing rods are placed in any soil, and the service life is about a century.

The advantages of bored technology with the installation of casing are highlighted:

- installation speed;

- year-round construction using anti-freeze concrete additives;

- screwing in piles and filling with concrete in a densely built-up region of a metropolis without the use of heavy aggregates;

- low noise level during operation.

When vibrating and screwing, modified technical mechanisms are used, which are compactly transported and conveniently placed in a small construction site.

Work rules

When installing the casing and performing packing, the regulatory documents SP 24.13.330, SP 28.13.330, SP 45.13.330, as well as industry and departmental guidelines are used. For a specific case, a work production project (PPR), standard technology cards for the process are made.

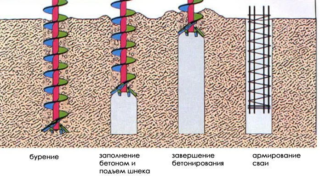

A drilling machine with a screw or drill makes a passage of the selected section and length. The wellhead is cased with a steel pipe section. The broadening at the bottom is performed if it is in the project. A documentary survey of the well is carried out after the completion of drilling. A reinforcing structure is placed in the trunk to increase the bearing capacity. Concreting is carried out by the method of a moving shell, concrete pipes are used. They are straight or telescopic.

Concrete is prepared on site in concrete mixers or brought from the factory. The mixture is constantly shoveled until it is put into the structure, but not more than 12 hours, otherwise the strength will decrease.

Recommendations for working on different soils

Metal and plastic capsules are placed in the earth layers:

- peat soils;

- clay soils, clays;

- sands, sandy loam;

- loams.

In watered formations, unstable, floating, subsiding soils, concreting is carried out no later than 8 hours after the completion of the well. In sustainable land categories, the standard time for starting concreting is extended to 24 hours.

If there is no possibility of laying the mixture within the specified timeframe, drilling should not be started until favorable circumstances arise. The drilling of the started passes is stopped at a level of 2 m to the design mark and no expansion is performed.

The choice of the diameter of the products

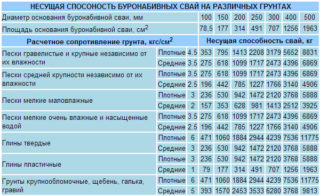

First, they collect loads from the facility under construction, calculate the actual pressure on the pile foundation. After that, calculate the required area of the base of the rack. But according to the tables, the square of the heel is picked up without calculation.

Take into account the fact that the actual load using the necessary coefficients should not be more than the calculated soil resistance. The corresponding value in the table is selected and the pile diameter is determined. Complicated calculations are carried out by engineering workers, whom the customer turns to to find the parameters of the foundation.