The technology of erecting residential and commercial buildings on supports is attractive for its high installation speed, material savings and the ability to do the work with your own hands. However, the condition for achieving the required strength and durability of the entire structure is a correctly selected and correctly implemented piping of the pile foundation. This technology is quite well developed, but the work must be thought out to the smallest detail even at the design stage.

Determination of the piping of the pile foundation

Each pile buried in the ground has a certain margin of safety and bearing capacity. During operation, the pipes are subjected to strong vertical loads. In addition, the soil presses on the supports when wet, heaving and drying. These conditions cause skewed products if they are not supported.

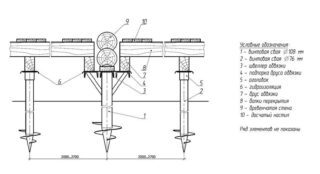

Screw pile tying is a procedure due to which all pipes are rigidly connected into a single structure. It is performed immediately after installation in order to exclude the slightest likelihood of violation of the vertical position of the products.

Tying the pile foundation with a bar is used in the construction of light frame, wooden houses, structures made of foam blocks or shields. In this case, the first row of crowns is both a grillage and a support for the beams. The strapping bar must be of high strength, hardness and moisture resistance. For its manufacture, expensive types of wood are selected, such as oak, cedar and larch. Then it is allowed to lay light and inexpensive fragments of spruce or pine.

What functions does the strapping perform?

Pile strapping is an integral part of the technology for erecting buildings on supports submerged in the ground. It is unacceptable to ignore it, even when erecting light and temporary structures.

The lining of the foundation with a bar performs the following functions:

- Uniform distribution of the vertical load across all supports, regardless of their number and location. This is important when, due to the peculiarities of the relief and soil, the columns have different depths and heights.

- Creation of a single and monolithic structure. Piling of piles with a bar allows you to combine individual elements into a common frame, where the possibility of their curvature or subsidence under loads arising at the corners of buildings is excluded.

- Ensuring pressure relief on the supports when surface technology is used, where the slab, which acts as a wide grillage, is poured onto the surface of the earth.

When erecting a foundation on piles, a non-contact method with floating fixation of the upper and lower elements can be used. This decision is made during construction in areas with high seismic activity.

Scope of the pile foundation strapping

Beam strapping is used in almost all cases of erection of structures on a pile foundation. Refusal of this process is allowed only when carrying out modular construction, when a pre-assembled base plate made of wood or reinforced concrete is lowered onto the supports.When using this technology, it performs the task of connecting the poles into a common system.

The use of a strapping for a pile field is advisable under the following circumstances:

- Conducting construction on unstable soils, the bottom of reservoirs and quicksand. In such conditions, the grillage keeps the pillars in a static position, regardless of the movements caused by changes in humidity and temperatures.

- Low level of freezing of the ground. Laying a deep belt-type foundation turns out to be excessively laborious and economically impractical. Drilling of point holes turns out to be more expedient, and the screw-in depth of screw piles can be up to 5 meters. In such cases, the strapping prevents the base from bending due to heaving of the soil.

- Rough terrain. Slight deviations in the height of the supports can be allowed on it. The installation of the grillage smoothes them, providing a perfectly flat surface for the construction of walls.

With the right choice of material and adherence to the installation technology of the piping, the service life of the support pile system will be at least 100 years.

Features of the work

The success of any construction depends on competent design. Even the highest quality grillage is not able to smooth out the defects made during the arrangement of the foundation.

The following rules should be followed:

- maintain a distance between supports no more than 200 cm;

- observe the vertical while screwing products into the ground;

- lower the pile blades below the freezing point of the soil;

- do not adjust the height of the supports by unscrewing them.

Piles can be screwed in manually or by using special equipment to this event. Depending on the type and density of the soil, the products are screwed into it immediately or wells are pre-drilled.

The strapping manufacturing method has its own nuances:

- Before installation, the timber must be treated with an antiseptic and a hydrophobic agent. This will protect the wood from getting wet and insect damage.

- The pile heads must be carefully aligned and only then the fasteners must be welded to them. The best option is a bracket in the form of an inverted letter P. After welding, the metal must be cleaned and treated with a corrosion agent.

- Waterproofing. Roofing material or several layers of dense cellophane should be laid on all heads. To prevent the material from moving during the installation of the grillage, it is better to glue it to the base.

- The connection of the strapping elements is made in the corners and on the heads. Fastening is carried out with steel plates and self-tapping screws. Each node and corner is additionally treated with anti-corrosion agents.

- The use of a double grillage. On top of the first crown with a thickness of 200 mm, a second tier with a thickness of 100-150 mm is laid with bandaging of the joints. This approach provides the structure with greater strength and stability.

During operation, the strapping requires regular care and maintenance. All elements of the structure must be periodically cleaned of dirt, mold and rust removed, and treated with anti-fungus and corrosion agents.

Methods for strapping the pile foundation

- Metal. T-beams and I-beams, channel or profile pipe are used. The products are distinguished by their high strength and durability. Massive brick buildings up to two floors high are installed on metal grillages. The disadvantage of such a solution is that the metal is flexible and, over time, bends even under its own weight. In addition, it will require constant processing of iron from rust. One more nuance - channeling of screw piles presupposes the presence and experience of working with a welding machine. All connections are made only in this way. It is not necessary to be a high-class master, but basic skills are indispensable.

- Bar.The undoubted advantage of this solution is the simplicity of material processing, for which even hand tools are suitable. The fragments are fastened with removable devices, so that the structure can be disassembled for dismantling or repair. The downside of wood is that it absorbs moisture. If you make a grillage from a damp timber, it can, when dry, lead to such an extent that it will affect the supports and walls of the building. Like iron, wood is prone to sagging, which requires additional supports between the piles. The problem is solved by using a glued profile bar, which is resistant to bending and twisting.

- Reinforced concrete grillage. This design is considered the most complex, expensive, but the most reliable and durable. The reinforced concrete strapping of the pile field is chosen when conducting capital construction or when planning a phased increase in the number of storeys of a building. The combination of stone and metal provides strength, little flexibility and complete protection of the steel frame from corrosion. Such a grillage is poured with concrete into the formwork installed on the piles, inside which the reinforcement is laid. As a form, it is allowed to use a channel, where a steel frame is installed in the cavity. The disadvantage of such a solution is the need to wait for concrete to harden and conduct construction only at positive temperatures.

The choice of the technology for strapping the pile foundation is a purely individual matter and largely depends on one's own skills and financial capabilities. However, in all cases, the decision must be based on complete and accurate calculations.