The advent of new building materials makes it possible to speed up the construction of buildings, reduce their weight and financial costs. Bricks were replaced by hollow concrete blocks. Universal building material is used for foundations and masonry walls. Thanks to the voids in the structure, it reduces heat loss and is cheaper.

Hollow Concrete Block Standards and Labeling

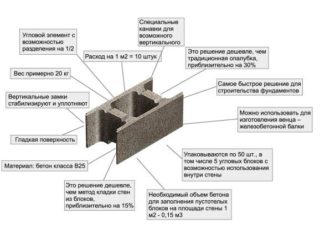

Hollow foundation blocks (FBB) are one of three types of concrete blocks. The standard for their production is determined by GOST 13579-78. The building material is made from various types of concrete, reinforcement is used for reinforcement. The geometric shape of the product is a parallelepiped, there are vertical holes in the lower part. The thickness of their walls is at least 100 mm. The recesses do not reach the surface by 30 mm.

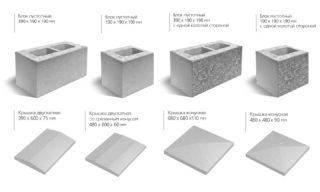

Product dimensions in mm:

- length - 2380 (24 dm is indicated);

- width - 400, 500, 600;

- height - 580 (rounded up to 6 dm).

The marking of products indicates their type, dimensions (length, width, height) in decimeters, the type of concrete and GOST.

Among the types of concrete used:

- T - heavy;

- P - porous with expanded clay filling;

- C - silicate.

Example of marking: FBP 24.4.6-С GOST 13579-78. The foundation block is hollow, length 2380 mm, width 400 mm, height 580 mm. The material is dense silicate concrete.

The marking is applied on the side part, it can be supplemented with the date of manufacture and the name of the manufacturer's company.

Specifications and features

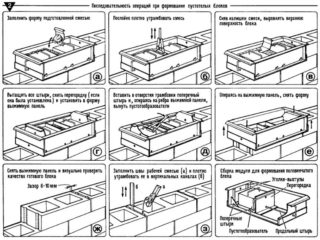

The products are manufactured by vibropressing. The casting takes place in a special mold. At the factory, this guarantees compliance with the specified geometric parameters. After compaction with vibrating devices, the composition is steamed. The procedure allows you to achieve a quick set of strength. The verified technology makes it possible to obtain a reliable material that can withstand bearing and dynamic loads during operation.

A feature of silicate concrete is the absence of cement in the composition. The blocks are autoclaved from lime and quartz sand. They are distinguished by a homogeneous structure and lower cost. Heavy silicate concrete provides the necessary strength, frost resistance, and sound insulation characteristics. Silicate-based products are rarely used in private construction.

Expanded clay concrete blocks, due to the addition of porous fillers (slag, fired clay) and plasticizers to the composition, retain heat better. The foundations of buildings are obtained with a low coefficient of thermal conductivity. Also, the structure is lighter than products made of heavy concrete. The disadvantage of the material is increased moisture absorption. This type of block is not recommended for the construction of foundations in areas with a close occurrence of groundwater.

When choosing a material, the climatic conditions in the region and the geological features of the site are taken into account. Designers suggest the type of concrete blocks that are suitable for the characteristics of the operating conditions.The voids present in the products during the construction of the walls of unheated buildings or utility rooms are filled with insulation.

The surface of the blocks has a different degree of processing:

- front - designed for painting and finishing;

- non-face - located in areas out of sight.

All products are fitted with two mounting loops made of a reinforcing bar with a diameter of 10 mm. They are necessary for the transportation of blocks, as well as for loading and unloading operations. The products have a significant weight (from 800 kg to 1170 kg), therefore, equipment is required to move them.

- The rectangular geometric shape of the hollow foundation blocks allows for a clear design of the basement walls and plinth.

- The products are designed for a long service life of about 50-100 years. They can withstand multiple freeze-thaw cycles and are resistant to seismic activity.

- The building material is fireproof, withstands the action of open fire and high temperatures.

- Block structures provide good sound insulation.

The speed of erection of a strip or columnar foundation is much higher than when working with bricks or using a monolithic strip casting. The erection of a prefabricated structure does not require waiting for the concrete solution to harden within a month.

Permissible deviations

The geometric dimensions and shape of the blocks must comply with standard norms, but small parameter errors are allowed:

- length - 13 mm;

- width - 8 mm;

- height - 8 mm;

- the size of the slots is 5 mm.

Products with cracks in concrete are not permissible, except for damage that has occurred on the surface as a result of shrinkage. Their width is no more than 0.1 mm for heavy grades and 0.2 mm for lightweight concrete. Not only size is important, but also the weight of the products. If it is less than the standard, errors were made during manufacture and voids formed inside the structure. The defect will negatively affect the strength of the block.

Scope and comparison with other building blocks

The hollow block is popular in various construction applications. In low-rise buildings, it is used as a material for load-bearing walls and partitions. A hollow concrete block is intended for residential and technical premises, outbuildings, garages. When constructing a strip foundation, the building material is used as a permanent formwork. Reinforcement is laid in the voids and poured with concrete. The result is a monolithic structure. Other areas of application:

- creation of a protective casing when laying pipelines;

- erection of barriers in road construction;

- material for the construction of fences and barriers;

- device of ramps and bridges.

- solid FBS;

- solid with a cutout for FBV communications;

- hollow FBP.

Structures have standard sizes and weights, they are produced from heavy, dense (silicate) or light (porous) concrete. Solid blocks have a larger number of standard sizes. Products are produced in lengths of 780, 880 mm, 280 mm in height. Their weight is less, so they are easier to use in private construction.

Each type of concrete block has advantages and disadvantages. Solid products provide maximum load-bearing capacity, can be used in various construction areas, and are suitable for all climatic zones. Their disadvantage is significant weight and cost, which are not always justified when erecting low-rise buildings.

In addition to concrete blocks, aerated concrete, foam concrete and slag concrete products are used for the construction of strip foundations and pillars. They are small in size and can be easily stacked by hand. The disadvantage of materials is their increased hygroscopicity. When using them, the costs and labor costs for the implementation of waterproofing increase. In terms of strength, cellular concrete is inferior to heavy and dense compositions.