The anchor holds the defined structure by anchoring it to the support base. The hardware is an effective type of fastening of objects, even with a significant mass and dimensions from various materials. The element is used in construction and repair, it provides secure fixation, therefore, the calculation of anchor bolts is important for the correct choice of modification.

- Defining anchor bolts

- Main types of products

- Curved

- Composite

- Removable

- Direct

- With anchor plate

- Calculation of anchor bolts

- In a group installation

- Determination of the pre-tightening value

- Spacing from bolt to foundation shear

- Anchorage depth

- General guidelines for the design of anchor bolts

- Installation rules

Defining anchor bolts

The bolt is held in place by friction and thrust. The expansion is created by the expansion of a steel collet or plastic dowel. The pressure (stop) received by the anchor arises in depth and is compensated by the internal obstruction of the material to bending, compression, and crushing. This principle is typical for metal anchors, foundation bolts.

The hardware is destroyed at the weakest site, while it happens:

- an explosion of a hardware product - an absolute or partial release while maintaining the integrity of the structure;

- cut - destruction along the border of the base under the influence of shear;

- break or bend - deformation under the influence of bending force;

- explosion of the base - destruction under a load that is higher than the bearing capacity of the base.

Corrosion can develop after the installation of anchors on some of its parts. The hardware is destroyed by heat and burns out.

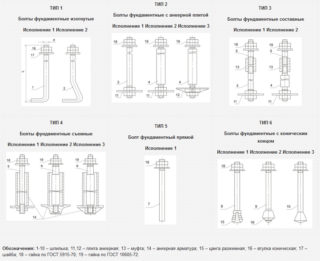

Main types of products

There are varieties:

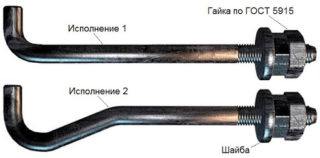

- curved with two nuts and washer;

- foundation bolt with anchor plate;

- composite section anchor;

- removable view;

- straight type with two nuts and washers;

- with a tapered end.

By size, small (length up to 55 mm, and sectional perimeter up to 8 mm), medium (up to 120 and 12 mm, respectively), large (220 and 24 mm) are distinguished. According to the installation option, there are spacer, wedge and driven ones.

Curved

A nut is located under the hook, which is used in the construction of bent hardware and serves to unclamp the spacer collet. This way the sleeve is securely fixed in the partition or load-bearing wall. The convenience of this type is that it can be removed at any time, if necessary.

These types are used in everyday life and are used for hanging lighting devices, boilers, and other devices. In other embodiments, the free end is bent into a ring and adapted to pull the rope.

Composite

The foundation combination bolt is used to fix the equipment in the support. The lower rod of the fastener with the anchor plate and the coupling is placed before the concrete is fed, and the upper part is screwed into the coupling. The equipment is screwed onto the stud, then the top is welded on.Metric threads are used and material is structural carbon steel, low alloy steel, or structural steel.

Removable

The sleeve expands with a wedge and is held firmly in the concrete by frictional forces. During installation, the wedge can be hammered into the collet or screwed into the thread. There is a type of fastener when the bushing is equipped with two expansion sections and blocks the hardware protrusion near the head and on the body of the anchor device. Such varieties are used to fix the filling of poyem, partitions, bearing profiles for panel decoration.

Direct

Drop-in anchors are mechanical varieties and consist of two elements:

- steel clip or other durable material;

- threaded pin screwed into the cassette.

Direct hardware is used in construction, they fasten objects of different massiveness, lightweight constructs, fix communications, household appliances and industrial equipment. Straight anchors are not installed in weak concrete or brick with cracks and other minimal damage.

With anchor plate

Before attaching the anchor to the base, a special glue or chemical solution is poured into the hole. With such fasteners, it is important to observe the application and curing technology, otherwise the bearing capacity of the connection may suffer. The operating time of each type after pouring the glue is indicated in the instructions. The anchor plate increases the support area of the object and additionally supports it.

Calculation of anchor bolts

The calculation of foundation bolts takes into account the following factors:

- dynamic characteristics, which depend on the direction of application of the force;

- the static pressure does not change and is taken according to the calculated indicators from the tables.

Manufacturers indicate the strength during packing, but the designers calculate the load-bearing characteristics for shear and break, while making a standard safety margin by applying the appropriate coefficients.

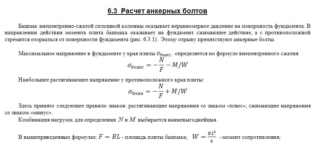

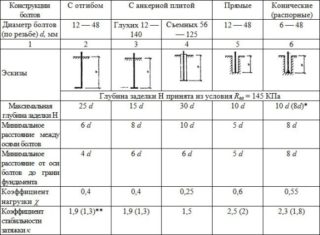

In a group installation

The load is calculated for the bolt that is subjected to the most negative stress.

The calculation of anchors to find the design pressure is carried out according to the formula P = -N / n + M · y1 / Σyt²where:

- N - design force;

- M - estimated bending moment;

- y1 - length from the pivot axis to the most distant hardware;

- n - number of anchors;

- yt - the length from the pivot axis to the 1st bolt (take into account pressed and tensioned fasteners).

The axis of rotation is assumed to be passing through the middle of gravity of the bearing area of the equipment. For through columns made of metal, steel vertical solid members and similar expressions are used to find the tensile load. The parameters of the concrete type, dimensions of the main surface, and the size of the compressed area under the column are substituted.

Determination of the pre-tightening value

Bolts are tightened to a certain degree of tightening F, the value of which for static pressure is taken as 0.75 P, and for dynamic loads, 1.1P is used, where R means the calculated pressure on the fastener. Tightening of construction hardware is carried out manually with the help of devices with an effort to an absolute stop.

The cross-section of the rods is checked for strength under dynamic influence, before installing the anchor according to the formula Ai = 1.8 g n kabout P / a Rwhere:

- g - pressure coefficient from the table;

- n - scaling factor, selected from the table;

- a - indicator of the number of load supply series;

- R - design tensile strength of the alloy (anchor material);

- toabout - coefficient according to the table.

The cross-sectional area of the bar is found from the reliability condition for dynamics and statics. Coefficient toabout take 1.05 or 1.15.

Spacing from bolt to foundation shear

If the bolt depth is increased by 5 diameters, the distance between the anchors can be made shorter by 2 diameters. The gap from the center of the bolt to the cut of the foundation is allowed to be made smaller by another 1 diameter, if there is a sheer reinforcement of the edge of the base at the installation site of the fasteners.

In any case, the span from the center of the head to the edge of the base is taken:

- not less than 100 mm for hardware up to 30 mm in diameter;

- 150 mm - for anchors with a diameter of 48 mm;

- 200 mm - for fasteners with a diameter greater than 48 mm.

If paired bolts are installed, a single anchor plate is used for them with a gap between the holes taken by calculation.

Anchorage depth

If the height of the base allows the bolt to be completely screwed in, the holes are drilled to the design size and, after installation, they are sealed with a mixture of cement and sand. If the size of the foundation does not allow to fully deepen the anchor, change it to a bolt with a bend with a spacer collet in the shape of a cone.

If the project requires a bolt with a size 3 times smaller than the mounted fasteners, the product is placed in concrete to the required depth. In this case, the condition is fulfilled that the hardware functions with absolute design resistance. It is possible to decrease the installation depth of the anchor bolts in proportion to the force acting on the fastener.

General guidelines for the design of anchor bolts

If the base heats up above + 50 ° C, the effect of the temperature on the anchor material is taken into account when performing the calculation. The effect of heat on adhesives or chemical fasteners is taken into account. Hardware working in an aggressive environment is taken into the development of a project with increased requirements.

Removable bolts are used to fasten conveyors, electrical and other heavy equipment, and curved bolts are designed for concrete wells of hardened foundations. Straight products on epoxy glue are laid to hold the floor and equipment together.

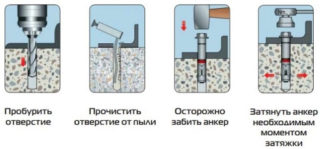

Installation rules

The bolts are placed in the well after mixing the mortar and preparing the hole. The fasteners are placed in the well, a little mixture is fed between the wall of the hole and the hardware. A vibration compactor is put on the rod, the solution is put into the dosing compartment. During installation, the vibratory compactor is rotated 20 - 30 °.