The foundation is the foundation of any structure, which must be as strong and resistant to various influences as possible. It takes the load of the building, precipitation. This structure is mostly underground, so its construction must be approached responsibly. The prefabricated strip foundation can be built independently.

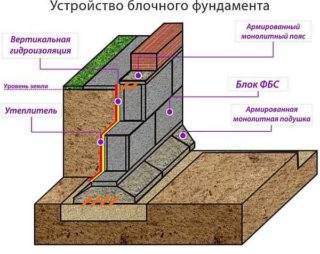

Prefabricated strip foundation device

The prefabricated foundation requires the use of special equipment, with the help of which the elements are transported and laid.

The blocks are trapezoidal or rectangular. Each element has a weight of about 300 kg or more, so it cannot be manually laid.

Varieties of prefabricated bases

The foundation can be classified according to several parameters: the material of manufacture, the depth of the foundation. On the first basis, the following structures are distinguished:

- Butovye. It is based on natural stone (chipped or smooth). Such a foundation is rarely used, since its compressive strength is low.

- Concrete. For work, FBS blocks of large sizes are used, as well as plates. The advantage of the design is the speed of construction. However, its construction is expensive. The reason for this is the use of a special technique.

- Brick. For the manufacture of such a tape, a clay or ceramic material is used. In this case, no construction equipment is required. The work takes a lot of time, so this material is only suitable for shallow foundations.

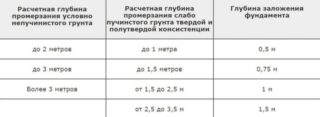

The depth depends on how much the soil freezes. If the value does not exceed 6 m, such a structure is considered shallow. When building it, you need to responsibly approach the calculations. Such a foundation is inexpensive, built quickly, but not suitable for heavy structures. In other cases, a base is required for the entire depth of soil freezing.

Application area

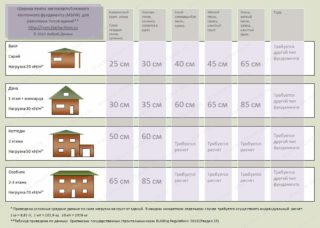

This type of foundation is used for the construction of brick buildings, houses made of foam blocks, cinder blocks, and monolithic concrete. The main condition for choosing a material for walls is a density of no more than 1300 kg / m3. The design is considered optimal if the site is characterized by soil heterogeneity. The scope depends on the type of foundation:

- Shallow brick is intended for the construction of wooden houses up to 2 floors. At the same time, the soil should not be heaving.

- Deep brick. This base is suitable for heavy stone or brick buildings. This foundation will allow you to equip a basement or basement.

- Shallow concrete. It is chosen for frame-type country houses, the height of which does not exceed 3 floors. It is acceptable on soft and non-porous soils. Not suitable for heavy structures.

- Deep concrete foundation. This design is suitable for houses of any configuration made of wood, brick or concrete.If the soils are heaving or freeze too deep, this type of base will not work.

The choice of the type of foundation depends on the weight of the building, climatic conditions of operation, as well as the financial capabilities of the owner.

It is necessary to choose a prefabricated reinforced concrete base in such cases:

- the use of heavy floor slabs in construction;

- high-density bricks or concrete blocks are used for the construction of walls;

- the need for equipment in the basement or basement;

- the soil structure on the site is heterogeneous.

An error in the choice of the construction of the foundation or the material of its manufacture affects the strength of the entire building, its durability.

Calculation of the parameters of the prefabricated strip foundation

For the correct construction of the prefabricated strip foundation, the drawing is carried out after careful calculations. If the strength indicator is underestimated, the shrinkage processes will be uneven, cracks will appear on the walls of the building, and the supporting structure may deform.

When the requirements for strength characteristics are overestimated, the labor intensity of the work and the cost of the structure unnecessarily increase. To calculate the foundation, several methods are used: according to the deformation of the soil, according to its bearing capacity under the sole. The second option is simpler.

The calculation is carried out as follows:

- Draw a diagram of the building in great detail: indicating the location of the walls, window and door openings.

- Determine the need for the construction of a basement (its dimensions are required).

- Choose the material for the basement floor, materials for wind protection, insulation, wall waterproofing.

The calculation takes into account the dimensions of the materials used and their specific weight. The process involves several stages:

- Collecting loads on the foundation. The mass of walls, floor and ceiling ceilings, rafter systems, materials for the roofing, all internal elements of the building, fasteners are summed up. The payload of the house (technical devices, furniture) should not exceed 180 kg / m2 of area. At this stage, wind and snow loads are taken into account. It uses tables of values for each region.

- Choice of tape dimensions. First, the width of the sole of the structure is determined. This parameter depends on the thickness of the walls, as well as the building and finishing material used. In addition to these dimensions, the depth of the tape is needed. The lowest point of the structure should be 15 cm below the level of soil freezing. In addition, the height of the base is taken into account. The depth of soil freezing can also be taken from official tables, depending on the region.

- Correction depending on conditions.

If the load of the house is less than the bearing capacity of the soil, all calculations were carried out correctly.

Advantages and disadvantages

Before building a prefab foundation, you need to consider its pros and cons. Design advantages:

- reduction of construction time: there is no need to wait for concrete to gain strength, since FBS are already ready for work;

- the ability to quickly start erecting the building box;

- high strength and durability of the structure;

- the possibility of building a foundation of any configuration.

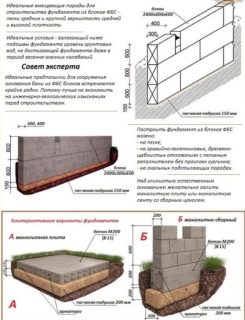

The disadvantages are the seams between the elements. They complicate the installation of waterproofing material somewhat. The strength of this type of base is slightly lower than monolithic. The work requires heavy equipment, which is expensive to rent.

Installation instructions

The assembly of the prefabricated foundation is carried out in compliance with the following technology:

- Site marking. For this, stakes and a cord are used. In this way, you can achieve an even and clear trench edge.

- Excavation. Using a shovel or special equipment, you need to dig a trench. Its depth depends on the bedding of the foundation and the weight of the structure.Depth deviations are allowed along the perimeter, but minimal. The bottom should be flat.

- Sand pillow making. Its width is usually 20-30 cm larger than the first layer of blocks. The thickness of the pillow is 20 cm or more. The sand needs to be moistened and compacted. Before laying the elements, a layer of waterproofing is laid on the pillow. Roofing material or dense polyethylene is used as it.

- Installation of the first row of blocks. It is made from a trapezoidal cushion plate. Since the bottom of the product is wider, the pressure on the ground is reduced, as does the risk of the building sinking.

- Installation of a reinforcing belt. On the surface of the slabs, reinforcement rods are laid, on top of which a concrete solution is poured.

- Installation of blocks. First, the corner elements are installed, as well as at the intersection of the walls. A cord is pulled between these beacons, which is a guideline for laying subsequent blocks. At this stage, it is important to observe the dressing of the sutures. Joints in adjacent rows must not overlap. Laying is carried out on a cement mortar. The correctness of the laying is checked using a building level and a plumb line.

- Seam sealing. The composition must be water-repellent.

- Laying the upper belt of reinforcement. First, the formwork is mounted, then a frame is made of steel rods, which is poured with concrete mortar.

- Applying waterproofing to the outer surface of the structure.

After completion of the work, the lateral sinuses of the structure are covered with sand and compacted. The last step is to waterproof the upper belt of the reinforcement. The laying of blocks should be started immediately after the preparation of the trench.

A prefabricated strip-type foundation is an expensive pleasure, but if the technology is followed, the construction process will go faster. With the right approach to work, the base will be strong and reliable.