Concrete is created by mixing a binder, filler, sand and water. The mixture laid in the formwork is looked after and optimal conditions are created for hardening and curing. In summer, the material is watered and covered with sawdust and films to maintain the humidity regime. Before loading, the strip foundation must be settled so that it does not collapse during the construction of the walls.

Strength gain

The mix structure and care conditions affect the deformability and strength of the final product. The physical and mechanical process of producing concrete begins with mixing with water a rationally selected composition of cement and filler. Gel-like particles appear in the mass of cement and water.

When mixed, the gel envelops the loose particles of crushed stone, hardens evenly, and a cement stone is obtained. The massif binds large and small particles into solid concrete, while the fragility and strength depends on the type of cement, the mass of water in the composition has a significant effect.

Strength gain:

- under normal conditions, concrete gains a maximum strength indicator within 28 days;

- if necessary, hardening is accelerated by processing in autoclaves (prefabricated products) and the required strength is obtained within 15 - 18 hours after preparation of the mixture;

- in construction, hardening accelerators and retarders are used, depending on the technology and end goals.

At subzero temperatures, concrete mortars slow down the set of strength, because the activity of hydration decreases. Unbound moisture freezes into ice, and its volume increases several times, and destructive stresses appear.

Thawing resumes hydration, but the damaged structure does not allow it to gain the required strength. It matters how long the foundation stands before freezing.

If the mixture gains 40-50% strength before icing, frost will no longer be decisive for obtaining the design physical and mechanical properties.

Grasping

Temperature affects the speed of the process:

- at an indicator of + 20 ° C (taken as normal conditions), the initial setting lasts 2 hours, and ends after 3 hours;

- a decrease to ± 0 ° С increases the time to 15 - 20 hours, while the onset of crystallization is postponed to 5 - 9 hours from laying;

- in autoclaves, the setting is 10 - 25 minutes.

Sometimes, due to unforeseen circumstances, the mixer shovels the concrete mixture already at the facility up to 12 hours. The mass does not harden, but a long delay in setting leads to irreversible changes that reduce quality. This is especially dangerous in the hot season, so it is better to use the brought mixture elsewhere, if possible.

Hardening

The process begins after the mixture has set. Hardening and obtaining strength does not last a month or two, but continues for several years. A period of 28 days is needed for a set of an approved brand of artificial stone. In the first days, the solution hardens quickly, then the procedure slows down.Concrete decreases in volume when solidified in air, and increases in volume when solidified in water (the mass swells).

Curing is influenced by factors:

- Brand and quantity of cement. An increase in the binder in the composition leads to a higher slump. Alumina and active cements enhance compression, while non-shrinking and expanding types do not reduce the volume of the mixture.

- The amount of water. It is recommended to take 1/2 volume of liquids from the volume of cement. Excess water will increase compression when solidified.

- The quality and size of the filler. Fine-grained components and porous materials (slag, expanded clay) give high shrinkage. It is recommended to introduce crushed stone of several fractions into the solution.

As accelerators used calcium salt of hydrochloric acid, sodium salt of sulfuric acid, calcium chloride and other chemicals.

The hardening mode is set by heating the mixture, the time during which the foundation should settle in winter in insulated shells, electrode heating, and covering.

Concrete details

Concrete must meet certain physical and mechanical characteristics, which include strength indicators, ability to adhere to metal reinforcement, and others. Depending on the place of application, requirements are imposed on frost resistance, heat resistance, corrosion resistance in an aggressive microclimate.

Concrete is divided according to the following criteria:

- Structure. Dense mixtures have no unoccupied interior space. Large pore - with little or no sand. Porous ones include cellular fillers, in which artificial microporosity is also imparted to the binder. Aerated concrete contains artificially obtained closed voids.

- Density. Particularly heavy ones have a volumetric weight of more than 2500 kg / m³, heavy - from 2200 to 2500 kg / m³, lightweight - from 1800 to 2200 kg / m³, light - 800 - 1800 kg / m³.

- Grain composition. Distinguish between coarse-grained mixtures, medium and fine-grained.

The required properties are set by the quantitative composition of the components and active additives that increase the required qualities.

Foundation shelf life

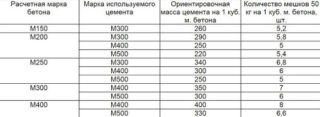

The type of foundation for the house is chosen taking into account the loads and properties of the soil. The strength and durability of concrete is influenced by various factors, for example, the composition of the mixture. For the foundation, cement grades of at least M250 are taken, otherwise there is a possibility of subsidence of the corners of the structure after a while.

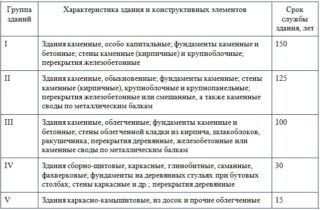

The service life of concrete is estimated at 50 - 100 years, it all depends on the preparation, working conditions and additives to improve the properties of the material. Durability depends on the type of filler. Crushed stone increases the strength, and the operating time of the support of the structure on slag concrete or expanded clay concrete has a boundary definition of 75 years.

The period of operation of the base without destruction also depends on the observance of the technology of laying the solution, attention is paid to the vibration of the layers, slow drying, and reinforcement. The type of concrete is chosen taking into account the operating conditions, for example, high humidity, permafrost, soil with increased heaving and other factors.

When to start building walls

After placing the concrete in the formwork, it should withstand almost a month before the time when you can continue building the house. This causes additional problems if the construction is taking place at an accelerated pace. But the condition of concrete hardening and strength gain remains unchanged, so all work must be stopped.

In the conditions of the construction site, it is possible to carry out other work that is not related to the load of concrete. It is allowed to disassemble the formwork in order to use the boards or boards on the next plot. After 10 - 15 days, the mass already hardens and holds its shape perfectly, therefore, no chips occur during the removal of the shells. If insulated non-removable formwork is used, the concrete hardens in it further.

It is recommended to remove shields, support beams and beams when 50% of the specified strength of the material is reached.The period of strength accumulation can be reduced by heating, but such actions must be performed technologically accurately and be justified.

Foundation conservation

The period during which the foundation can stand without a house is not regulated, but it must be taken into account that in winter it can swell without load. More often, such a danger arises for the strip base, on which the soil exerts bending, twisting and pulling forces when the soil moisture freezes.

Conservation work:

- the tape is cleared from the formwork, because the tree swells with moisture and contributes to the wetting of the concrete;

- the side and surfaces and the top are treated with waterproofing mastic or roll material is used;

- they make a drainage system around them, if this was not done during the development of the zero cycle;

- use roll insulation, then the surface of the foundation and its sides are wrapped in cellophane with fastening the edges from the wind, you can put bricks.

It is necessary that the foundation stand until 100% strength is obtained without frost, only then it is preserved for the winter. Monolithic slabs, columnar structures are also insulated from moisture, insulated and covered with a waterproof film. Pile foundations must be reinforced with metal strapping before the onset of cold weather.

Gentlemen, it is already possible to load the foundation when it reaches 70% of the brand strength. And this happens during the first (summer) two weeks. And in 28 days, concrete is gaining branded, and not maximum strength. Do not mislead people. People build houses for themselves, not launch pads for spaceships, to wait a month after the BS is flooded.