For suburban construction, a pile foundation is often chosen. A properly assembled structure will last a long time, its integrity will not depend on the influence of external factors. Such a foundation is used in the construction of industrial buildings and residential buildings. If you follow the technology, you can do it yourself.

Construction and design of the pile foundation

A pile foundation is a supporting structure, which includes a pile field or free-standing elements. For their manufacture, reinforced concrete is used, although there is the possibility of using rubble concrete or reinforced mortar. Often, timber is used for one-story buildings.

Supports must be mounted at the corners of the structure, at the intersection of the load-bearing inner walls with the outer ones or between themselves. The distance between the main piles should not exceed 2 meters, but if it is more, additional elements are used.

Before the installation of the pile structure, its design is carried out:

- Taking soil samples to study its composition and nature, for which test drilling is performed.

- Dynamic and static soil research. The procedure will allow you to study the degree of soil mobility.

- Pressiometric test. Shows how much soil can be compressed at the construction site.

- Testing with reference pile elements. The type of elements used is determined.

- Experienced work. Find out the nature of the interaction of the foundation with the ground, neighboring buildings.

After completing all the procedures, you can start creating the project. All possible influences of internal and external factors are taken into account.

Classification of pile structures

By installation method

Driven piles are finished products, for the installation of which special crane installations are required. They pull the piles to the desired point and drive them using hammers. There is a variety of stuffing elements. They are made directly at the construction site. First, a well is prepared, a reinforced frame, and then a concrete solution is poured.

Screw piles are a metal rod, at the end of which there is a spiral. Most often they are used in individual construction. The disadvantage of screw piles is their relatively short length - up to 6 m. The bearing capacity of such products is not very high. To erect a building on such a foundation, lightweight building materials are used.

According to the layout

Often, the elements are separate from each other. They are mounted under maximum load points. Sometimes products form pile tapes. The structure consists of one or more rows of elements. The task of such a foundation is to transfer the load to the reinforced foundation.

The disadvantage of the pile foundation is not very high reliability, so for heavy buildings it is better to use "bushes" from the supports. This placement is suitable for soft soils or groundwater close to the surface.

By material of manufacture

The following materials are used for the manufacture of piles:

- Reinforced concrete. Such products are hollow or monolithic. Reinforced piles can last up to 100 years.They are made directly at the construction site or in production conditions. The first option avoids the use of expensive equipment.

- Steel. A pipe, rolled steel is used for the manufacture. The thickness of the metal should be 0.8-1.2 cm. The section can be rectangular or round. To protect the material from rusting and corrosion, it is treated with bitumen. The disadvantage of this type of product is its high weight.

- Wood. These are relatively light products with a diameter of 22-34 cm. Only hard types of wood are used for manufacturing.

Wooden piles are rarely used, since the material is prone to rotting, damage by insects and rodents.

Materials and tools used for work

To build a solid foundation, you must first prepare for work. The following tools and materials are required:

- scrap;

- shovel;

- Boer;

- piles;

- roulette;

- concrete mixer, welding machine;

- building level.

For the preparation of concrete you need cement, crushed stone, sand.

Pile foundation construction technology

- Drilling holes. Their number is determined by the total weight of the structure, as well as the operational load. The borehole diameter depends on the technical parameters of the drill, but it rarely exceeds 30 cm. The depth of the hole is not more than 6 m. The drill is positioned so that minimum efforts are involved during operation.

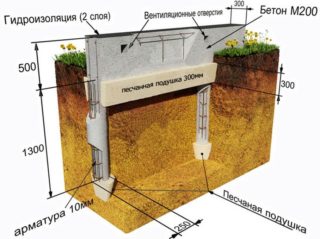

- Concreting and reinforcement of elements. To protect products from moisture, roofing material is placed in the wells along the entire diameter. After that, piles will be placed in the pits. Concrete is used to secure them. At the same time, groundwater is pumped out. It is also important to organize the frame from the reinforcement. Concrete must be fed in layers and compacted.

- Grillage device. Its height is at least 30 cm, width is at least 40 cm.

At the end, all joints are filled with cement mortar.

Pros and cons

The advantages of arranging a pile-screw foundation:

- low labor intensity of work;

- no risk of subsidence of the structure due to an increase in the level of groundwater or heaving of the soil;

- suitable for any type of soil;

- reducing the cost of building a foundation;

- reduction in the volume of earthworks;

- high speed of construction;

- the possibility of arrangement at any time of the year;

- frugality.

Among the shortcomings are the difficulties with summarizing communications, the impossibility of arranging the basement. When erecting a structure, the manufacture of a grillage is required.

A pile foundation is an excellent solution for small light houses if they are built on heaving or soft soils. However, its design must be approached responsibly.

a neighbor made an extension to the house on screw piles 4 years ago, and this spring 3 piles went underground, so it's better to pour concrete or fill it yourself.