Each node of the strip foundation affects the degree of reliability of the final construction. When arranging the base, it is important to pay attention to waterproofing.

Definition of strip footing

This type of foundation has the form of a closed configuration (tape) made of reinforced concrete. It performs the function of transferring the load from the walls of the room to the soil. The walls of the building are erected on the sides of the base. Such a foundation is used more often in individual private construction than in industrial construction. When compared with slab bases, material and labor resources are consumed much less, which determines the popularity of reinforced concrete belts in the summer cottage sector. This is one of the least expensive foundation types. Buildings with a basement or basement can be erected on it.

Such a base is only suitable for stable, non-porous soils. In the case of “problem” soils, it is better to prefer piles or slabs.

Sectional strip foundation

On the tape, you can build a small outbuilding, a wooden, stone or brick house. In the second case, the base is created on a layer of sand and gravel, covered with a waterproofing material so that the embankment is not washed away by groundwater). If a barn or a bathhouse is being built, the pillow may not be used. In advance, you need to prepare drawings with descriptions.

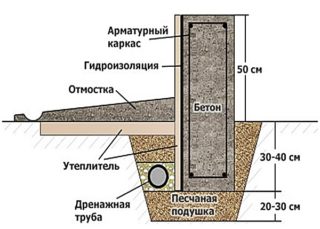

The section of the foundation is determined by its structure. Contains reinforced concrete sections lined with a waterproofing layer. Above the ground level there is a blind area designed to protect the tape from moisture. The widened part located on the bulk cushion is the sole of the base.

Each foundation unit carries an important functional load. Neglecting certain components will adversely affect performance.

The sectional view of the strip foundation is also influenced by the level of deepening. If it is small (0.5-0.7 m), the base can only withstand light construction. It is not suitable for the construction of a brick house. In this case, the deepening should be 0.3 m below the freezing point of the soil.

If it is decided to make the base monolithic, the reinforcement frame is knitted directly on the object and then poured with a concrete mixture. This design is durable, but freezes for a long time. This view is easiest to do on your own.

There are foundations consisting of separate blocks of industrial-made reinforced concrete. Such a foundation is mounted quickly, but the strength of the structure is lower than that of solid options. In addition, the process will require the hiring of workers and the rental of specialized equipment.

Description of foundation waterproofing units

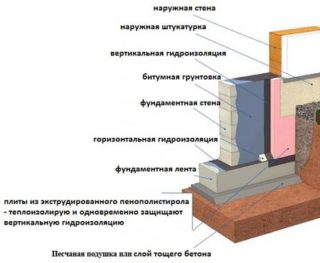

Before arranging the base, it is necessary to analyze the characteristics of the soil, in particular, groundwater and other sources of fluid. Sometimes moisture enters the soil from seepage waters. Excessive liquid content in nearby land gradually destroys the base. To prevent this, you need to properly organize protection. For this, a drainage system can be used to remove water from the building. A waterproofing foundation assembly is also required to protect the base from moisture ingress.Layering of special materials is carried out.

A common option is paint formulations. Crushed stone impregnated with bitumen (layer 10 cm) is leveled with cement grade 100. Then the surface is primed and paint insulation of type 1-5 is applied. Before laying the structure, a cement screed is made from the same mortar. Used for insulation and asphalt compositions. In this case, the crushed stone is primed with bitumen.

Protective materials

The foundation waterproofing unit can be made of different materials. They are laid out on the protected surface in layers in 2-4 steps. Examples would be:

- paint insulation using material of type 1-5;

- pasting layer 7 or 8 type;

- cast with raw material type 4.

Sometimes a combination of different types of materials is practiced. For example, type 5 asphalt insulation is applied to the primed crushed stone with bitumen impregnation. Then, a material for reinforcement (fiberglass) is placed on the screed (3 cm) and grout (1 cm) made of cement. 2 types of paint insulation are applied on top.

Important nodes of the strip foundation

Saving on the main components will easily turn into a decrease in performance. Walls can begin to crack, and molds appear in the basement. To prevent this, you need to responsibly approach the arrangement of the nodes.

Foundation support unit on the ground

This is the bottom of the pile expanding from top to bottom in the pile-strip foundation. It must have a sufficient area to determine which you need to know the bearing capacity of the soil. A weight equal to half of this parameter should press on 1 cm². In loamy soil with high moisture, the bearing capacity is 1500 g / cm², so when erecting a building on it, it is necessary to provide such an area of the sole so that no more than 750 g is pressed per cm².

Reinforcement

It is important to correctly calculate how many ribbed reinforcement will need to be purchased for the foundation. An insufficient amount of it is potentially dangerous and makes the foundation unreliable. It is also irrational to spend a lot of money on excess reinforcement.

Node for supporting the floor of the first floor to the foundation

Even if backfilling is used during construction, the floor should rest primarily on the foundation. Otherwise, after several years of operation, it may crack or sag. This is due to shrinkage movements of the bed.

Perfume

When the construction involves a ventilated subfloor, a sufficient number of airflows must be made even before the foundation is arranged. The distance between them should be equal to 2.5 m. If you do not take care of the air vents in time, their subsequent installation will require significant resources.