Prefabricated reinforced concrete products FBS are used for the construction of strip foundations. The elements are equipped with mounting loops for installing the blocks in the design position. The base is a bulk, monolithic or prefabricated foundation pad. The weight of the FBS is taken into account in the calculation when collecting loads, therefore, the optimal dimensions and structure with or without voids are chosen.

Description of foundation blocks

Blocks are used in conditions where monolithic construction is undesirable for a number of reasons. A prefabricated foundation is built quickly and does not require 28 days to cure. For installation, excavators and cranes of automobile or tower type are involved, because the weight of the concrete block does not allow it to be installed due to the physical strength of a person.

Standard characteristics of FBS blocks:

- water resistance class W2;

- volumetric weight of material 2.2 - 2.5 t / m3;

- do not collapse at 50 freezing and thawing courses (group F200);

- block strength 100 - 110 kg / cm2.

The blocks are made of rectangular concrete, a reinforcing cage of a certain type is placed inside. The weight of artificial stones ranges from 0.24 to 1.96 tons. Plants produce products with different qualities, a set of properties is determined by special modifiers in the composition of the concrete mixture. Produce products with increased resistance to moisture or freezing. Metal frames are made taking into account the operating conditions, reinforcement or linear profiles are used for longitudinal laying.

Varieties of foundation blocks

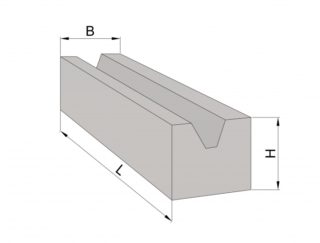

The range of products is given in the document GOST 13.579-1978. The height of the elements ranges from 30 - 60 cm, the width is 30, 40, 60 cm, and the length is 0.9 - 2.4 m. The length dimension includes the width of the assembly joint between the blocks, therefore the actual dimensions of the stone are always 20 mm less in all directions. The material is heavy (B7.5 - B15), silicate concrete (B10 - B12.5), expanded clay concrete (class B3.5 - B 7.5), while the weight of the FBS block depends on the brand of cement and filler.

They produce types of prefabricated blocks for the foundation with the designation:

- standard solid products - FBS;

- stones with voids inside to reduce weight - FBP;

- blocks with cutouts for communications or pipes - FBV;

- prefabricated pillows for the support of the structure - FL.

Foundations work in compression, bending, under pressure from the structure, as well as from the heaving of the soil. There are prefabricated blocks for columnar supports, which are called reinforced concrete glasses. Some types of products have a thickening in the lower part, which is made in the form of a step.

Solid (FBS)

The type of solid structures is characterized by high strength compared to hollow groups. Most often, these blocks are used for building the foundation of a building, erecting walls of an economic underground and technical basements. The elements have a rectangular shape with or without internal reinforcement, it depends on how much the FBS block weighs.

Manufacturing technology involves vibration of the mixture to achieve a standard size with a smooth surface. Violation of the process leads to the appearance of irregularities, therefore, gaps are obtained when laying blocks and the strength of the foundation tape decreases.

Characteristics of solid structures:

- the material for solid stones is heavy concrete with an average density of 1.8 t / m3;

- standard sizes in width are 30, 40, 50, 60 cm, in height - 28 - 58 cm, length - 1180, 2380.

- the mounting ears are placed 30 cm from the edges of the block, flush with the plane.

Deviations of dimensions in length allow ± 13 mm, width and height - ± 8 mm, tolerance for the dimensions of cutouts and holes is ± 5 mm. The norms allow a deviation of straightness by 3 mm along the entire length of the prefabricated structure, while there are small deviations from the nominal mass of the FBS.

Solid with a cutout (FBV)

The manufacturer provides for a longitudinal recess in the block so that water supply, sewage or other communications can be laid. Sometimes FBV products are made according to an individual order, which takes into account the specific direction of the cut on the surface or the through hole inside the block. How much the concrete block weighs depends on the number of grooves.

Characteristics of FBV products:

- length - 88 cm, width - 40, 50 cm, height 58 cm;

- weight varies from 0.28 to 0.58 tons, depending on the size of the block;

- the volume of the product is 0.161 and 0.202 m3;

- steel is 0.76 kg in total weight.

For mounting hinges, smooth hot-rolled bar rebar of VSt3 ps2, VSt3 sp2, class A240 or periodic rods of grade 10 GT of class Ac 300 are taken. ... Requirements for reinforcement brands are set out in the document GOST 13.015.

Hollow (FBP)

Hollow elements are manufactured in a standard length of 240 cm, but differ in height and width. Prefabricated structures with closed internal air cavities are produced vertically or horizontally. FPB blocks have a lower mass in comparison with the size and weight of FBS, but their use is strictly regulated.

Lightweight types cannot be used for building the base of a house in wet soils. Soil liquid can penetrate into the body of the foundation and accumulate in cavities. During frosts, water expands and breaks the concrete mass, internal cracks appear. Microcracks and crevices are not allowed in concrete, with the exception of local shrinkage defects.

External bundles allow:

- dense and heavy silicate mixtures - 0.1 mm;

- light compositions - 0.2 mm.

The quality of reinforcement and steel elements of the reinforcing frame is regulated in GOST 10.922. The manufacturer gives a guarantee for the compliance of the manufactured products with the requirements of regulatory standards, GOSTs or technical specifications TU. The consumer is responsible for the rules of storage and storage of blocks, the transportation is controlled by the organization that is engaged in transportation.

FBS characteristics and scope

Piece reinforced concrete stones are placed in conditions where monolithic pouring cannot be performed due to various circumstances:

- remoteness from the concrete plant;

- cold climate, which slows down the hardening of the mixture in the open form;

- construction at an accelerated pace;

- reduction of labor costs at the construction site.

Tower cranes are used either on the basis of a car, depending on how much FBS 4 (standard) weighs or take into account the weight of FBS 6, as well as other types of artificial concrete stones. Prefabricated strip base structures are not erected on penetrating soils and subsidence layers, because a strip of composite blocks does not work well for bending. In this case, a substrate is placed from the FL foundation pads of a trapezoidal section.

Unstable soils are developed for a foundation made of prefabricated elements, if a load sharing scheme is made in the form of a pile-grillage foundation or a monolithic slab is laid. Individual blocks are alternated with monolithic inserts to increase bending resistance. Prefabricated parts are mounted with bandaging of seams.

The installation of blocks with cutouts contributes to the industrialization of the work, the FBP products facilitate the foundation and reduce the pressure on the ground. If constructions with slag or expanded clay filler are used, thorough waterproofing is done, geotextiles are used.

The brand and dimensions of the most popular type

A common type is full-bodied items of a certain size. The weight of the 40 60 240 foundation block (width, height, length, respectively) differs depending on the weight of the inner frame and the type of cement used.

Mass of stones:

- in the FBS 24.4.6 - L brand, concrete B 7.5 is used, the reinforcement weighs 0.76 kg, while the mass of the block is 0.79 tons;

- brand FBS 24.4.6 - C - concrete B 15, the frame weighs 0.76 kg, the block has a mass of 1.09 tons;

- grade FBS 24.4.6 - C - concrete B 7.5, reinforced metal frame 1.46 kg, the finished block tightens 1.3 tons.

The width of the trench for blocks of 40 cm is taken 1 m more than this size for laying an insulating material, a layer of waterproofing and a drainage device. The depth of the pits is determined by the height of the foundation elements, a gap is added for sand or crushed stone filling, laying of concrete cushions.

Self-calculation of the required number of blocks

The width of the block depends on the transverse size of the wall; the foundation is usually made of the same dimensions. The number of rows of prefabricated elements is taken taking into account the height of the base of the house. The length of the stones is chosen so as to minimize the number of joints and seams that weaken the structure and let the cold pass.

To find the amount of concrete stones, the following methods are used:

- load calculation using formulas;

- counting using a ready-made online calculator;

- contacting the technical specialist of the design office.

They draw up a plan for the layout of elements with a dimensional grid before ordering blocks at the factory in order to determine the standard sizes. Long products are placed on an extended section, and small-sized parts are used when turning and at corners.