Concrete works well in compression but is hardened with metal to increase flexural and tensile strength. To connect the bars to the frames, reinforcement knitting is used. The number of metal elements, their diameter are determined by preliminary calculation in accordance with the plan. Steel wire is most commonly used, but plastic clips are sometimes used.

Tools and materials for knitting reinforcement

In the frame of a reinforced concrete product, annealed binding wire with or without zinc coating is used. The heat-treated material does not stretch, its fixing properties are improved compared to the cold-drawn look. Galvanized wire is more resistant to aggressive environments.

The diameter of the knitting rod depends on the diameter of the steel bar in the frame, usually a wire with a thickness of 0.8 - 1.4 mm is taken for reinforcement of 6 - 12 mm. Bigger rods are knitted with reinforced wire, but there are no strict restrictions on the choice of diameter. The use of a knitting rod with a cross-section of less than 0.8 mm is difficult, because it will burst from the pull. Wire larger than 1.6 mm is difficult to pull into a strong knot.

Knitting rebar can be done by hand, but the process is accelerated with the use of tools:

- crochet hook;

- knitting gun;

- screwdriver with an adjustable number of revolutions;

- welding machine.

Hooks are sold in the store, there are simple, semi-automatic and screw models. A simplified version is done with your own hands. Using a hook requires effort. Pistols are used in conditions of large construction, save time and effort of the worker. The device is held in one hand, and the other is used to support the elements.

The screwdriver is useful for home use, while a homemade hook is inserted into the chuck. Welding is an alternative option and is used as recommended in the project.

Work technology

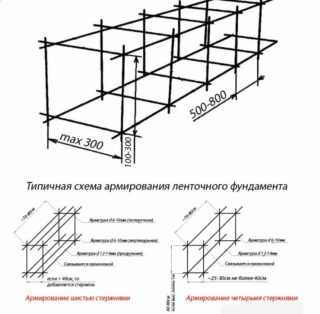

Tying reinforcement under the strip foundation is performed using the following technology:

- A formwork made of wood or other materials is installed, a fishing line is stretched inside it to indicate the upper plane of the foundation.

- From below, 5 cm in height is marked, from this level the layout of the longitudinal rods and the bandaging of the joints begin. Bricks are placed at the bottom so that such a condition is met, and the vertical reinforcing elements are stuck into the ground. Steel rods are also spaced 5 cm from the walls of the formwork.

- Longitudinal elements are made in one piece for a length of 6 m. A bundle of rods with an overlap of 25 - 35 cm is allowed if the foundation is strip. The slab is long. Metal rods are exposed around the perimeter, the upper and lower reinforced belts are strapped on them.

- The concrete is poured in layers after the end of mating, while vibration is applied to forcing out air bubbles.

The reinforcement cage can be knitted in sections outside the formwork and sequentially installed inside the trench, but more workers are required for installation in this way.No debris and foreign objects are allowed in the nodes, the connection should not have protruding loops and uneven tightenings with free ends of the wire.

Reinforcement knitting methods

The most common practice is to connect reinforcing bars using crochet hooks. The elements are spliced according to the scheme, while the longitudinal strips are joined in three places (at the beginning, end and in the middle) with an annealed wire. Smooth rods without corrugation are connected with bending of the ends.

Before joining, the material is transferred into the trench, laid out according to the scheme, and leveled. Dimensional elements (bricks, plastic clips) are placed under the first belt so that after pouring all the rods are covered with a layer of concrete.

There are several ways to correctly knit reinforcement:

- wire;

- welding;

- plastic clamps.

The first method is laborious, it differs in several options for composing nodes, in different techniques. For tightening, mechanical and electrical tools have been developed that speed up the work process.

Plastic clamps are self-tightening, save significant time, but have some restrictions on their use. Welding is selected for certain types of fittings if the letter C is in the brand name.

Wire

Not only tape types are reinforced, the frame is placed in columnar supports, columns, foundation beams, monolithic sections of floors and coverings.

Features of knitting of different designs:

- Columnar elements are reinforced with rods without lateral corrugation, therefore mechanical tension of the nodes is applied when using a wire connection. Knitting modules are fixed with collets or hooks, you can use a gun.

- Slab and strip bases contain a frame with an upper and lower mesh (belt). It is necessary to connect the reinforcement with the tension of the longitudinal elements so that they do not fall during the pouring process. Attention is paid to joining at corners.

The lower rods can fall out of the frame and end up directly in the ground after concreting, which will lead to corrosion and a violation of the bearing capacity of the concrete. For binding reinforcement in high base structures (more than 1.8 meters), scaffolding and scaffolding are arranged. When concreting wells, the frame is knitted using descending trays, cradles and traverses.

Binding wire knots do not deteriorate under the influence of aggressive concrete components. The joints are distinguished by their elasticity, which increases the resistance of structures to deformation, increases their strength when bending forces appear under operating conditions.

Welding

Frameworks are welded in civil and industrial construction due to reduced labor intensity, joining of fittings of different sizes, assembly automation. Joint teams of concrete workers and welders work at large sites, but reinforcement workers are not recruited.

The frame is welded in the following ways:

- contact;

- electric arc;

- semi-automatic;

- electroslag.

The connection along the length of the reinforcing bars is carried out by a contact, semi-automatic method, and for spatial nodes, an electroslag, arc version is used. The process takes place at a current from 250 to 350 A, cold-hardened metal is joined at a high current of short duration (hard welding).

The contact method allows butt welding of rods of various diameters, which saves material. Equal strength connections are obtained when the difference in cross-sectional dimensions is not more than 1.25 - 1.5 mm. Often vertical and longitudinal elements are designed with different diameters, and resistance welding firmly unites parts of the strapping, posts, corners and chords.

Restrictions are associated with the type of metal for the frame. Some steels are specially processed during production and are thermally hardened so that a structure is reproduced inside that increases the strength.The high temperature during welding destroys these structures and the load-bearing capacity decreases.

Popular fittings with the designation ASH, A400 cannot be welded - they are connected in other ways.

Plastic clamps

The popularity of synthetic binders is gaining popularity, but conservative builders do not trust such a connection. Clamps securely fix parts of the frame, but their use has specific features. The advantages include ease of tightening, the process does not require special training and tools. The clip is pulled together until it clicks, the action takes little time.

A frame made of smooth reinforcement does not resist dynamic forces well, the fasteners can crack if a person steps on the upper longitudinal structural elements. Consider the fact that the clamps can be damaged if the concrete vibrates during pouring.

Many builders use the frame as a leg support when concreting, but this cannot be done with a structure on plastic yokes. Vibration with power tools will damage the connection, and coarse aggregate can crack and cause the assembly to come loose.

Experts do not recommend using plastic clips in frosty weather, because the material cracks when exposed to negative temperatures. A variant of polymer clamps with a metal strip in the middle has been developed; such elements have more possibilities for application. New types of plastic are used that do not deteriorate in the cold.

Correct use of the hook

The process of forming a knot:

- A piece of wire 30 cm is folded in half and the point of intersection of the reinforcing bars is clasped so that the loop at the bend is opposite the tails.

- The hook is looped into a loop, grips the ponytails and rotates to wrap the ends around the loop.

- The resulting knot is tightened with effort, without bringing the wire to break.

- The hook is removed from the loop, the remnants are trimmed.

Screw hooks are used, which belong to semi-automatic devices. The tip rotates progressively in the device. If you pull the hook towards you, the tip makes a turn and the wire is tightened. The worker makes minimal effort, and the time to create a knot is reduced by 3 to 5 seconds.

The wire also folds in half, the hook is wound into a loop, the end is wrapped around the loop and the hook is pulled towards itself. Turning the handle tightens.

Wire selection

Wire is taken to fasten the frame rods. The product is not made specifically for tying and is a type of rolled metal according to GOST 32.82 - 1974. Wire rod is suitable for tying reinforcement in a structure.

A material of circular cross-section is taken, the diameter is determined individually for each frame or adopted according to the project. If it is not possible to buy annealed wire, you can strengthen the existing one by holding it over the flame for 25 - 30 minutes, then leaving it to cool in the open air.

Experts advise to fold the knitting rod several times, so that between the folds there is the desired size (30 cm), and then cut off the fold sections with a grinder. This speeds up the process of cutting the knitting rod to size, so as not to measure the required length each time.

The exact wire consumption is difficult to determine, so a preliminary calculation is used.The number of nodes is taken at the joints of longitudinal elements with vertical posts, corner joints, reinforcement joints along the length are taken into account. One connection takes about 0.3 - 0.5 meters of wire, this size is multiplied by the number of connections and the required footage is obtained.

Advantages and disadvantages of tying reinforcement

The connection of elements with wire is a laborious process and is used for small volumes of construction production. Wire knots are cheaper than welded joints because for the latter, electrodes are required, and the operation and transportation of the apparatus also requires material costs. Galvanized wire will hardly deteriorate over time.

Welded joints are less durable, the work requires skilled workers to exclude burn-out of steel, and only certain reinforcement is used as a material. After concreting the foundation, the structure shrinks. Wire connections give freedom, so tension in the frame is eliminated. Welded joints are destroyed by shrinkage and are not used in areas of unstable ground, such as swampy areas.

Wire connections do not violate the internal structure of the metal, and welding rebuilds the structure due to the action of high temperature. Plastic clamps have a different coefficient of expansion compared to concrete and steel, therefore, when the temperature of the reinforced concrete structure changes, they can crack.