A well-designed and equipped base of the house transfers to the ground the mass of the building, the weight of snow in winter and the payload. In order for the building to be reliable and its construction did not entail unpredictable consequences, you need to imagine how the foundation is poured.

Soil analysis and design selection

Before pouring the foundation of the structure, you need to study the characteristics of the soil in the area where it is planned to put the house, and choose the option that is most suitable for the given conditions of the structure. It is necessary to find out what type the soil belongs to in terms of its composition, to determine the bearing capacity and the location of the groundwater. These characteristics determine the depth and overall configuration of the foundation.

Conducting construction work without understanding and taking into account the characteristics of the soil can lead to unpredictable consequences for residents. It can also result in the choice of an irrelevantly complex design that requires a lot of resources, or, conversely, insufficiently reliable performance in pursuit of economy.

If we neglect the study of the soil for the occurrence of water, clogging of the drainage with silt or washing out of sand is possible. It is also necessary to investigate the internal structure (the presence of water-saturated, unstable areas) and the type of relief (flat, with a slope, etc.), the presence of drops. The latter is important in the context of the development of an architectural project - for example, it determines whether a basement or basement floor can be made.

The foundation for the house is poured taking into account the characteristics of the building and the surrounding space (the presence of extensions, fences, etc.), the raw materials used, technical and economic factors. Some common materials used for the construction of walls (for example, blocks of foam and aerated concrete) are especially whimsical to the soundness of the base, since they can crack under bending loads.

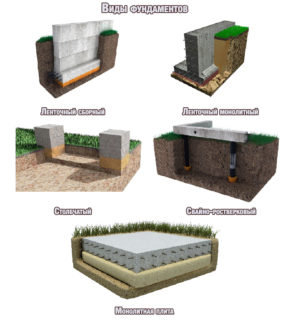

- Pole-based base - suitable for lightweight buildings erected on non-rocky, stable ground.

- Slab foundation, ideal for year-round use. The downside of this type is significant thermal inertia, which is why it is not very suitable for summer cottages.

- Tape design, the advantages of which are ease of construction and a wide range of possible applications. Such bases are common in low-rise buildings for various purposes.

- The foundation is on metal piles. There are different options for its execution, for example, bulk and with the use of screw structures. This option is also suitable for areas with significant elevation differences.

The best soils for building a house are considered to be coarse sandy and dense, moist clayey. In such conditions, even the tape design will provide reliability.

It is better not to build structures on some soils. These include peat, chernozem, silty, saturated with water. These soils are subject to replacement or special consolidation measures.

The choice of concrete and its manufacture

Before pouring the base, you need to select a suitable concrete mixture. In suburban construction, samples with strength indicators exceeding M200 are used. It is better to entrust the selection of a concrete grade to specialists. This is especially true for the construction of multi-storey buildings: lack of competence can lead to dangers for residents.

To make concrete at home, you will need gravel, sand and cement. The components are taken in a 4: 3: 1 ratio. To achieve frost resistance, additives are added. The mixture should not be too liquid. Water is added in an amount of about half the volume of dry matter. Strength can be assessed by non-destructive testing technology or by comparison with a typical sample.

Calculation of concrete for the foundation

It is necessary to calculate the strength class of the material used for concreting. The parameter is usually expressed by the letter M with an accompanying number. Typically, for suburban construction, the M300 brand is used. Smaller numbers are used for non-residential lightweight buildings, and larger numbers are used for multi-storey buildings.

You can calculate the volume and weight of concrete using the online calculator by entering the requested data in the blank fields.

Required materials and tools

For marking, you will need wooden stakes 1.1-1.3 m long, a twine and a knife for cutting it, a triangle and a plumb line. In addition, you need to prepare a long construction tape.

An important part of the work is mixing the concrete mix. This can be done by hand, but to save time and achieve better quality and consistency, use a concrete mixer.

You will also need reinforcing elements for the frame (rods with a diameter of 1 cm) and boards or plywood for formwork (2.5 cm thick). Conifers are better suited - when using such a material, there is less chance of cracking. You will also need anchoring bars (5 cm diameter) and zinc-coated wire. The function of fasteners is performed by self-tapping nails. From the tools you will need pliers and a stapler.

Preparatory work

In order to properly fill the foundation for the house, you need to pay attention to marking work and creating a frame into which concrete will be poured.

Step-by-step diagram for a strip base:

- Marking the boundaries of the foundation. It can be carried out using pegs and connecting them with twine. Accuracy is checked by measuring the diagonals with a tape measure and comparing the result with the plan. In addition to the outer perimeter, you need to mark the inner perimeter with stakes.

- The next stage is digging a trench for the foundation according to the existing markings. You can do this job with a simple shovel, or lift the soil with a tractor or excavator. The more massive the building, the greater the width of the trench. The ditch deepens below the level of soil freezing (0.7-1.5 m). The bottom is rammed and leveled.

- Creation of bedding under the foundation. First, a layer of river sand is poured (0.15 m). Having rammed it, 0.2 m of crushed stone is poured.

- Creation of a formwork that defines the boundaries of the foundation. It can be made removable - such a structure is removed from the trench when the concrete hardens enough - not earlier than after 2 weeks. On the outside and inside, the pits define the boundaries with plywood boards or shields. The sections of the connection are supported from the outside by beams. You can fasten the boards with self-tapping screws - this simplifies the subsequent dismantling of the formwork. The slots for the pipes of communications are made in the shields in advance. To prevent the tree from being impregnated with mortar, it is upholstered with polyethylene. On very dense clayey soils, formwork can be dispensed with. In this case, the flooring is made of polyethylene so that the concrete does not dry out.

When the formwork is ready, the base is reinforced with metal rods. They are tied with wire pieces. The density of the mesh depends on the mass of the building.

Foundation casting process technology

The concrete mixture is poured into the frame immediately, without technological breaks, and compacted. To make it lie flat, the tapping of the boards is practiced. Simultaneity is important for the reason that pouring over an already frozen composition predisposes to the appearance of air cavities, due to which the structure can crack.

Working with a concrete mixer

The preparation of the mortar will go faster if you use a concrete mixer. The number of working cycles is determined by its performance. A concrete mixer truck is a good choice for optimizing large-scale construction. But its use will require additional cash costs for transportation.

How to fill in winter

Sometimes the foundation has to be poured in winter. The phased structure of such work differs from that performed in the warm season.

Since water during the preparation of concrete can freeze prematurely, antifreeze components are introduced into the composition. A tent structure is installed on the site, inside which heat guns are placed.

So that the poured mixture does not harden so quickly, the formwork is made of expanded polystyrene. There is no need to dismantle it.

How to fill in parts

To prevent the formation of voids, each batch of the mixture is prepared immediately before pouring. The maximum interval between cycles is 2 hours in the warm season and 4 in the cold. If you have to take a long break, it should not exceed 64 hours. Before pouring a new portion, dirt is removed from the concrete surface and treated with a stiff brush to improve the quality of adhesion.

Work under a wooden house

A shallow strip foundation is suitable for a log house, but if you plan to make an underground room, the foundation is laid 0.2-0.3 m below the freezing point of the soil. The area where the work is carried out must be level and at least 3 meters away from the neighboring ones. The work is carried out according to standard technology. An edged board is well suited for formwork.