A solid fuel gas generator converts wood, coal and charcoal into gaseous form. In this form, it is more convenient to use fuel, in addition, emissions into the atmosphere are reduced. The wood-fired gas generator is loaded with pellets, waste from the woodworking industry, the remains of boards, parquet and other types of organic construction waste. A special device is purchased ready-made or they make a gas generator with their own hands.

The design and principle of operation of a wood-fired gas generator

IN gas composition includes:

- flammable carbon monoxide (CO);

- methane (CH4);

- hydrogen (H2);

- hydrocarbons (alkenes, alkadienes).

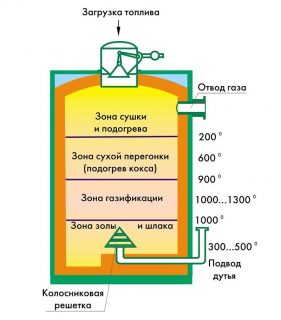

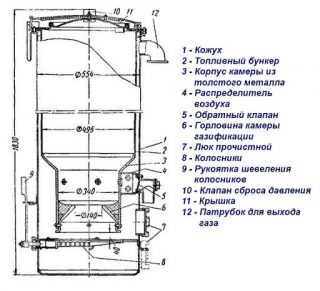

Steel cylindrical body has a loading chamber for fuel, the door is equipped with a seal. Firebox located below, between it and the body there is a neck with a gasket made of asbestos cord. Air enters through an opening connected to lance (air distribution tank).

The building has hatches:

- at the top with a shock-absorbing lining to regulate the pressure;

- for fuel filling;

- for cleaning the ash pan.

Inlet fan increases power, allows you to use firewood with high humidity (from 50%). Grate set to collect ash, their central part is movable for easy cleaning. Behind the body is vortex filter for rough gas cleaning. Then the gas mass is cooled in the tank, delivered to fine cleaning chamber... Before use the gas in the mixer is saturated with air.

Scope of application

Technical devices are actively used in practice due to their effectiveness. Generating sets convert biological fuels, wood residues, into gas.

High performance allows:

- heat the room;

- work an internal combustion engine in a car.

The gas generator plant is used if it is unprofitable to use electricity. For example, they put it near construction sites and new buildingsnot yet connected to the mains. Use aggregates in hospitals or factorieswhere continuous energy is needed. In the absence of electric current, the backup pyrolysis gas generator is triggered.

there is autonomous gas generating devices different functionality. They are acquired if solid fuel units are converted to low-grade fuel.

Industrial applications

Gas generators are placed on dwood processing plantsto burn waste, which is abundant in production. Fuel is prepared by grinders and crushers, which are stationary and mobile. This is how the fuel of the required structure is created after deforestation.

The industrial gas generator engine features characteristics:

- efficient burning of firewood;

- purification of the surrounding space and atmosphere;

- the possibility of laying low-quality combustible materials.

Large production plants equip with automation, so there is no need for the presence of an employee.

Household installations

Home gas generators usually have a capacity not more than 15 kW, but there are separate models with an indicator of 25 kW. For household use, provide power with a margin of about 20 - 30%... Installations are classified according to the duration of operation, the type of generator, and the type of fuel.

When choosing, take into account:

- number of phases;

- liquid or air cooling;

- manual or automatic start;

- open or closed housing;

Hot gas from a gas power plant for a private house can be used in the heating system, dry with his help fuel, things, vegetables, other products... For drying, a part of the gas pipeline is circled around the firebox, placed between the loading chamber and the body.

Work safety units provide:

- thermostats;

- safety valves;

- monitoring sensors;

- emergency shutdown schemes.

Electronic control modules coordinate the work, make it possible to set the required parameters, remote control of the console and via the Internet is provided. Required provide for smoke extraction... The minimum dimensions of the room where the gas generator is located should not be less 15 m³.

Pros and cons of technology

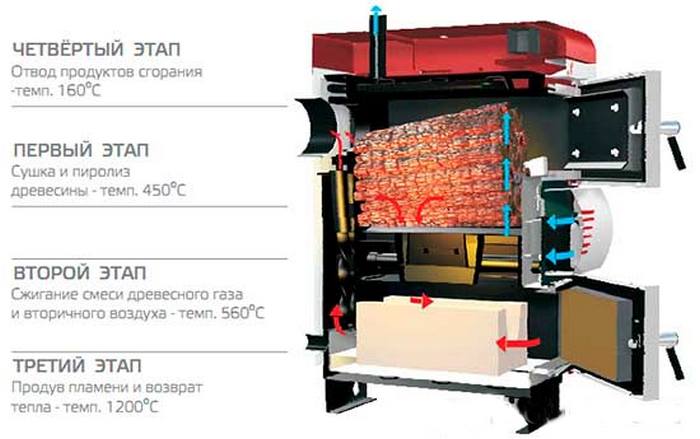

If there is no need for separation of the gas mixture, the natural gas generator works efficiently as a heat generator, provides heating for the house. The benefit is that due to the use of pyrolysis gas firewood is saved.

Some businesses buy units and produce generator gas, receiving money for disposal of waste from other factories... The cost of garbage disposal is high, and fines are possible, so wood waste is easier for woodworking companies to hand over for processing and pay less. The owner of the station benefits from paying for the work, he also has free heat for his needs.

Making a gazgen on the wood with your own hands

Given the high cost of finished units, they are considering the option of hand-made production. At the preparatory stage draw up drawings of an autonomous gas generator.

Electricity from gas is obtained by assembling a structure according to the scheme:

- Housing. The base of the unit is assembled from steel sheets, the parts are marked according to the dimensions from the drawing.

- Bunker. The tank is designed for storage of pallets, firewood. They are made of iron sheets, fixed in the case, the nodes are delimited by a plate of low-carbon metal.

- Furnace chamber. It is placed at the bottom of the bunker. The material is heat-resistant iron, and the lid is sealed with a gasket to prevent oxygen from entering.

- Throat compartment. This is where the resin cracks, so the area is separated by asbestos spacers from the main body.

- Air distribution box. They are placed outside the casing, and the fitting is embedded using a check valve.

The neck is joined to the firebox using a pipe and filters.

Required materials and tools

Needed low carbon steel sheets, cook heat-resistant seals for caps, necks... Asbestos is used more often, but it is considered unhealthy, so other types are taken (silicone, silicates). For the firebox, they successfully use old gas cylinder or iron barrel.

It will take instruments:

- welding machine;

- electric drill, grinder;

- hammer, vise, chisel, pliers;

- tape measure, core for metal, square, level.

Prepare for air injection fan, the parts are fastened by welding, bolts and nuts are used in some places. The filtration unit is made from used fire extinguisher housings... For the grate they take heat resistant iron rods or use finished products in size.

Stages of work

at first assemble the body, at the top are installed in it bunker for firewood (cubic capacity about 60 - 70 liters). Alternative fuel tank underneath equip combustion chamber. The filter is made in the form zigzag collector, mount a faucet to drain the condensate.

Further stages of work:

- install grate bars;

- a branch pipe connects the fuel chamber with the olefin combustion section;

- a cooling system is brought out into the branch pipe, which is located outside the casing;

- an air distribution box is mounted on top of the unit, a check valve is installed.

For the doors, they take reliable hinges. The finished generator is connected to the chimney.

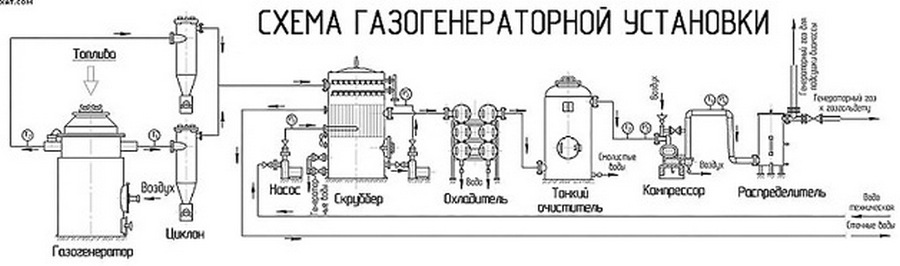

Gas cooling and purification

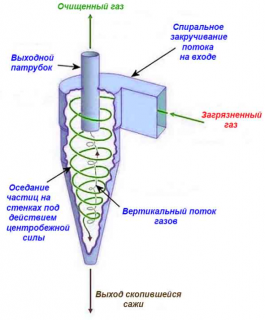

Gas outlet the mass is cleaned of impurities:

- coal particles;

- soot;

- sintered elements.

Cleaners are dry dynamic, surface wet, flushing liquid. For efficiency, use chambers for coarse and fine cleaning.

Gas cooling is one of the necessary technological procedures so that temperature stresses do not arise. The system includes several air coolers together with fans.

Ignition fan

The generator is fired up by tractionwhich is created in the chimney due to the pressure difference.

The process can be started:

- fan;

- by gravity.

Mixer

This node is installed for coordination of the proportion of the supplied gas mixture... Wood gas has a calorific value of 4.5 MJ / m³, and natural gas - 34 MJ / m³. Therefore, the concentration of air and fuel must be regulated, which happens when using a damper.

The cleaned mixture enters the mixer, while a certain volume of air is supplied. This the mass becomes usable as a water heater for domestic needs, in the form of fuel for internal combustion engines. The mixer is equipped with dampers for quantitative and qualitative coordination of the gas composition.