The service life of a gas pipeline is the period of service of the mains, which is calculated from the moment of installation or repair to the development of the technological resource of material and equipment. The duration of use of pipes is determined by the manufacturer, which is indicated in the accompanying documentation. After the end of the service life of gas pipes in an apartment building, their commission examination, technical check is carried out, after which an act is drawn up. The document indicates the possibility of extending the period of operation or the need to replace communications.

Commissioning of gas pipelines

Gas supply to residential buildings is carried out through fan-type pipelines. Several distribution substations are installed on the way of gas supply to the settlement, the last of which is mounted inside or outside the building. Further, gas is supplied to the apartments through risers, where there are branches from them to the meters, and from them to consumers (stoves, columns, boilers). Wiring and connection diagrams are carried out in accordance with the established rules and regulations. Compliance with the technology is checked by special control services.

Putting gas pipelines into operation is permitted subject to the following parameters:

- pipe wall thickness - 3 mm for underground and 2 mm for external;

- diameter - 15-100 mm;

- design pressure - 3-12 atmospheres;

- ceiling height - from 220 cm;

- the gasket is separate, not in the air ducts or next to the heating riser;

- not opposite windows and doors;

- free access for inspection and repair;

- the presence of effective natural ventilation;

- lack of combustible materials in the finish;

- only welded connection using couplings;

- the use of special devices for fastening to walls.

Reception of intra-house communication consists of checking the status of the following criteria:

- welding of joints;

- coloring (for iron);

- material of manufacture;

- tightness of the system.

The act indicates the next period, no later than which the next check will have to be carried out.

Factors affecting the condition of pipes

The service life of a gas pipeline depends on a number of objective and subjective factors that can extend or shorten it. Practice shows that most of the aboveground and underground highways retain their performance even after the end of the warranty period, sometimes exceeding it several times. However, there are frequent precedents when the network collapsed long before the end of the billing period.

The operating time of communications is influenced by the following reasons:

- Errors in design leading to subsequent deformations and ruptures.

- Violations of laying technology, expressed in weak joints, ignoring the use of sleeves when passing through walls.

- The quality of the materials used during the installation.

- The content of alkalis and acids in the soil, leading to metal corrosion.

- Air humidity.

- Compliance with the schedule for the inspection of structures.

All these factors lead to the fact that pipes from the same batch can serve completely different time.

Maintenance

Regular maintenance of gas pipelines makes it possible to identify and eliminate an emergency situation and extend their service life.

Maintenance of gas pipelines includes the following activities:

- External examination for the detection of external damage, corrosion, peeling of the protective coating.

- Monitoring the performance of shut-off and control valves.

- Checking the tightness of the system by pressing.

- Restoration of the integrity of the joints.

- Removing rust, applying a new protective coating.

- Replacement of emergency fragments.

- Checking the equipment for leaks and the possibility of leakage.

Only qualified employees of the gas service have to perform these manipulations.

It is forbidden to independently interfere with the system, check it with an open flame, or put bandages on the pipes.

Renovation work

Scheduled pipeline repair works are carried out after the expiration of the warranty period established by their manufacturers. However, a routine inspection is carried out every 5-10 years, depending on the operating conditions of the system. Special devices are used, various examinations are carried out. Based on the results of the audit, a protocol and a work plan are drawn up.

There are the following signs indicating the need for repairs:

- thinning of the walls;

- violation of welding seams;

- leak detection;

- the appearance of rust;

- discharge or fading of paint.

This process is carried out in the following sequence:

- Shut off the gas supply to the riser.

- The pipeline is pumped with air.

- Damaged areas are cut out.

- New pipes are welded.

- The system is checked for leaks.

- Steel parts are painted yellow, and in apartments to the taste of the residents.

The final stage is drawing up an act of completed work.

Calculation of the degree of pipe wear

When planning inspections and repairs of pipeline systems, gas service specialists are not limited to external examinations and laboratory studies. Such events are productive, but it is simply unrealistic to cover all houses in a big city with them.

To develop a schedule for repairs, specialists use formulas developed on a scientific basis and observation practice.

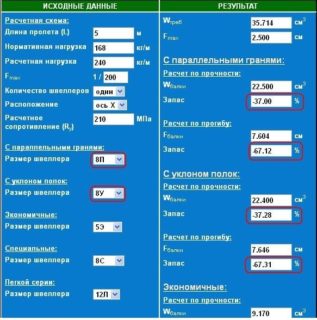

For calculations, the following initial data are taken:

- design voltage;

- strength factor;

- Wall thickness;

- minimum long-term strength of the material.

Indicators imply the technical properties of the material at an air temperature of 20 degrees.

Gas pipeline service life

If earlier steel was used exclusively for the construction of pipelines, today it is gradually being replaced by polyethylene. Each material has its pros and cons, which should be discussed separately.

Iron pipes have the following advantages:

- high strength;

- tightness;

- the ability to connect by welding and threading;

- versatility of laying (underground and on the surface).

Disadvantages of the material:

- heavy weight, complicating installation;

- tendency to corrosion;

- lack of the necessary flexibility;

- formation of a large amount of smoke and debris during assembly, danger of fire when using welding.

The service life of a gas pipeline made of steel pipes is 40-50 years.

Advantages of plastic systems:

- simplicity and speed of assembly;

- increased bandwidth;

- resistance to corrosion and decay;

- no need for additional finishing.

Disadvantages of products:

- pressure limitation up to 1.2 MPa;

- insufficient strength;

- connection only by welding;

- cannot be laid in the ground;

- loss of shape and softening when heated above 80 degrees;

- destruction of the structure under the influence of ultraviolet radiation.

The estimated service life of a polyethylene gas pipeline is 50-80 years.

Service life extension

Service life is not a permanent category, it is calculated on the basis of calculations, tests and data aggregation obtained from statistics from previous years. The operational period can be extended if the safety of the facilities where the communications are installed is ensured. Experts assess the conditions for using pipes, after which they issue forecasts, which are scientifically based conclusions and proposals.

The gas pipeline can be operated after the expiration of the warranty period, if, according to the results of diagnostics, no serious defects in the system, as well as tendencies to their occurrence, are found.

There are the following rules for extending the operational life of a gas pipeline:

- regular inspection of communications;

- use of high-quality valves and control equipment;

- Do not use the pipeline as a support for furniture or for attaching clotheslines.

If you have the slightest suspicion of damage to the gas pipeline, you need to urgently call 104.