Biological wastewater treatment methods have a number of advantages, one of which is the ability to be used for large volumes of household and industrial waste. The main active link is microorganisms that feed on nitrogen, proteins, carbohydrates, fats, acids. Bacteria break down organic matter to neutral components - gas and water.

The device and principle of operation of the biological treatment station

Many methods have been proposed, but only one of them is completely safe and provides the degree of purification after which water can be used for domestic purposes - a deep biological treatment station for a country house, because it is where there is no centralized drainage of wastewater that there is a problem with their disposal ... After final filtration at home, the water is drinkable.

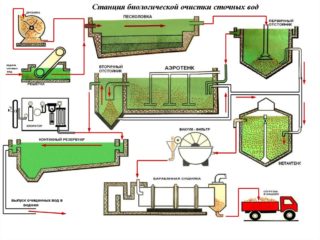

Biological wastewater treatment scheme

- Waste flows through the sewer pipe to the station. First, they are mechanically cleaned through grids, sand traps and grease traps. All these mechanisms are built into the system.

- The liquid, cleaned of solid particles, enters the sump, where the bulk of the suspended particles settles to the bottom.

- It is pumped or drained into a secondary clarifier, from it into a sludge tank, where bacteria work that eat organic matter.

- Semi-purified liquid is driven through the aeration tank. In it, the liquid is enriched with oxygen, and the water is also purified with the help of microorganisms. On the one hand, biomass from bacteria is fed, on the other hand, water, which must be purified. The aeration tank looks like a long corridor. Due to oxygenation, microorganisms multiply and their total mass at the exit increases several times.

- Next, it is necessary to separate the bacterial mass from the purified water. For this, the liquid is driven into a sump. Biomass is a suspension with a concentration of microorganisms from 0.4 to 0.8%. Part of the suspension is disposed of, and part is left for further multiplication and use in the process of running water through the aeration tank.

- The effluent goes to a mixer, where it is disinfected with chlorine.

- Further, the water can be used as technical water or discharged into a natural reservoir without danger to local flora and fauna.

There are various configurations of biological stations operating both electrically and by gravity.

For the cleaning process with varying degrees of contamination, a minimum amount of microorganisms must be present in the water. It is also required to observe the oxidative density, that is, the amount of oxygen dissolved in water.

Advantages and disadvantages of SBO

- economical use of electricity, the ability to work by gravity;

- the degree of water purification is close to 100%;

- long service life - more than 50 years;

- the station body does not corrode, as it is made of polypropylene - industrial plastic;

- there is no need to add biomass, since the technology allows using part of the activated sludge after settling for further purification of liquids;

- suitable for private houses, restaurants, industrial enterprises, apartment buildings and other establishments;

- easy to install, does not require repair costs;

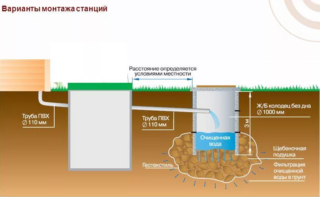

- installation is carried out only by the underground method, so the station does not take up space on the surface of the earth.

The disadvantages of the system are manifested in the case when the configuration of the treatment plant is selected incorrectly. For example, the runoff is carried out into the soil to the filtration fields, but the soil in this area does not absorb water at such a rate as provided by the station. In this case, the fields become silted up and restoration work must be carried out.

Once every 1 - 3 years, depending on the volume of the tank, it is necessary to carry out a complete cleaning and replacement of activated sludge. These are additional costs. However, if you consider how much it will cost to constantly pump out wastewater using a sewage machine, installing a biological treatment station will be a profitable solution.

If it is impossible to mount pipes at a slope, you will have to install a pump to pump the wastewater. This will incur electricity costs.

If the drains come in small portions, the system works without interruptions. If you give a large volume of liquid at the same time or flush chemistry down the drain, microorganisms will suffer. They will die, and new ones will have to be populated and multiplied over time. In such situations, water cannot be used, since it comes in an unpurified form. This moment does not apply to all types of cleaning stations, but only the cheapest.

Some systems have no fat protection function. The bacteria do not digest it, therefore, when leaving the treatment plant, the water will be oily. Additional grease traps must be installed in the kitchen.

Materials used

In the installation of biological treatment plants, plastic materials are used that are resistant to ground movement on the site and are able to withstand winter temperatures. The pipes connecting the tanks are also used plastic, calculated according to the technical characteristics for external sewerage.

There are models that involve the installation of plastic containers in a concrete frame. These are expensive structures, but sealed. The smell on the site with complete sealing will not appear.

Installation features

- the septic tank is placed no closer than one meter to the foundation of the building;

- it is necessary to strictly observe the dimensions of the pit for the container, since a decrease in the sand cushion causes it to be compressed by the soil and, as a result, damage to the walls, depressurization;

- a sand cushion is poured onto the bottom or a concrete foundation is made due to the close location of groundwater;

- pipes suitable for the septic tank are also sprinkled with sand to avoid deformations;

- the depth of laying the sewer pipes is taken into account, based on the climatic conditions of the area.

The first step is to prepare the pit and strengthen the walls. Install the container, make a hole and connect the inlet and outlet pipes. The gaps between the walls are filled with sand, which is filled with water for compaction.

Further, pipes are laid in the trenches connecting the septic tank with the house. After testing the system, the trench is covered with sand.

Review of biological treatment stations for a private house

- Topas;

- GRAF;

- Eurobion;

- Bioxy;

- Ergobox;

- SBR;

- NV;

- UPONOR;

- SANI;

- GRAFPicobell;

- Unilos;

- Eurolos.

The cheapest, but not the most practical, are Bioseptics from Topas. The slightest excess of the amount of wastewater leads to disruptions in the treatment.It is not recommended to drain water into the area, especially if fat separators are not installed. The manufacturers themselves declare that they would not drink such water, although a 98% degree of purification is declared. This firm uses a lot of advertising tricks that generate sales, but the result is a waste of buyers' money. The price of a biological treatment station for a private house Topas starts at 79 thousand rubles.

The NV system of autonomous cleaning is considered to be the most productive and reliable, starting from the materials of manufacture (fiberglass reinforced plastic with a long-term guarantee), to the technology of water purification and sedimentation. The activated sludge storage technology allows users to sometimes drain household chemicals into a septic tank without the risk of irrevocably killing microorganisms. Some of them remain and are capable of reproduction.

SANI, GRAFPicobell biological treatment stations provide long-term functionality and uninterrupted operation. They are ranked on a par with the NV brand in terms of quality.

Owner reviews

Mikhail, Kazan: I put a septic tank with Topas brand bacteria in my private house. Dissatisfied, as I have to throw out large sums every 3 months for inspection. They advised another brand in the store, but decided to take it cheaper, it turned out that it was impossible to put a heavy load on it. You can immediately see what kind of dirty water flows into the ditch. It's good that they didn't reuse - the filters in the house would have to be changed every day.

Evgeniy, Smolensk: They put Topas in the country. We rarely visit, so there are no special problems so far. In the summer, we use purified water to irrigate the site. We were advised to install a fat trap - we did the right thing by agreeing. At neighbors two houses, the water comes out clean, but oily. It turns out that bacteria do not utilize it.

Marina, Voronezh: We have a big family - someone is constantly bathing or cooking in the kitchen. The house is two-storey, 3 bathrooms, 2 washing machines. They advised NV, they said that the bacteria will survive when the chemistry is dumped, but we still try to use natural detergents. They are satisfied with the septic tank, it works without interruptions. We use water for washing the car, watering the garden. Plants react normally.