One of the important types of land work in the construction of a cottage / summer house is the installation of a drainage system on the site. It helps to drain the soil or remove excess moisture from the building with high quality.

Definition and purpose

- adjustment of the water balance of the soil with an excess or high level of groundwater;

- removal of moisture from buildings and structures, provided there is a large average annual rainfall in the region.

Indicators for the last item can be obtained from the local meteorological service.

Types and arrangement of drainage systems on the site

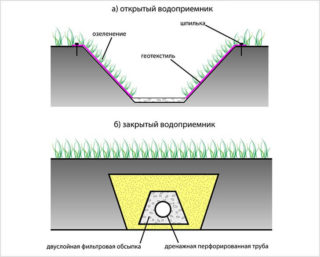

- Open, aka surface drainage. Communication is preferable at a normal level of soil moisture (groundwater does not flow above the 2.5 m mark) and subject to a large amount of precipitation. Arrange open drainage in a point and linear way. The system is laid no deeper than 50 cm from the surface of the earth. More often these are gutters with gratings or canals simply prepared in the ground with rubble, gravel, and broken brick strewn at the bottom. The latter option is good for garden plots.

- Deep drainage (underground). In this case, the system serves to drain high groundwater (at a level of 1.5 meters and above). The pipes are laid in prepared channels, wrapped in geotextiles, sprinkled with rubble and buried. All drains are interconnected and slope towards the discharge point or septic tank / storage. To control the efficiency and operability of communication, manholes are installed at the points of bends and turns of the system.

Excess moisture is dumped into nearby ravines, into aeration fields, into the central sewer main. In this case, all the water must be transported by gravity. If the relief of the site does not allow the drains to be sent without pressure, a pump must be connected.

Drainage design and necessary calculations

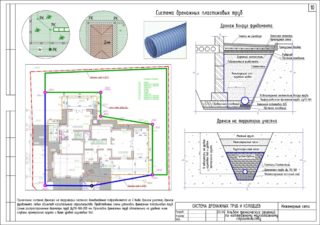

When installing a drainage system around the house and its foundation, all communications should be designed first. To do this, you need to take into account the following parameters:

- groundwater level;

- type of soil on the site (sandy, sandy loam, clay, etc.);

- installation depth of channels / drains;

- the length and diameter of the laid pipes;

- the level of the slope towards the point of discharge of effluents;

- distance between stacked drains / trays.

All parameters and points of location of drains (their beginning and end) must be indicated on the diagram.

Experts recommend making a distance of 20 to 22 meters between the channels if the soil in the area is loose. If the soil is clayey, the drains are laid at a distance of 10-11 meters.

For the deep system, the channels are laid at the level of 0.7-1.5 meters. In this case, the drains should be located 30-40 cm below the groundwater level. According to SNiP, the slope of the system is observed at the rate of 1-2 cm for each of its running meters.The larger the cross-section of the pipes, the smaller the slope can be.

Choice of materials

- Ceramics. The option is not entirely convenient for private construction, since the material is heavy and expensive. At the same time, the resistance of ceramics to aggressive media and temperature extremes is excellent.

- Asbestos cement. Drains have a smooth inner surface, which increases the flow rate of water in them. However, it is not very convenient to work with such material due to its heavy weight.

- Stainless steel. Heavy, yet corrosion resistant material. Serves up to 15 years.

- Polymers: PVC, polypropylene or HDPE. LDPE or HDPE drains are ideal. They are resistant to low temperatures, flexible, durable, and have a smooth inner surface. At the same time, the weight of the material allows you to work with it even alone.

For the installation of deep drainage communications, it is worth taking pipes of brown or green color. They are designed for outdoor use.

In addition to drains, you need to prepare the following materials:

- Wells: inspection, overflow, overflow, storage. They can be made from ready-made corrugated pipes, which is very convenient, or they can be independently assembled from brickwork, reinforced concrete rings and even car tires. The latter option is laborious and not always durable.

- Crushed stone. Serves as a primary drainage layer to prevent fine sand and debris from entering the pipes. However, you shouldn't take limestone material. It is destroyed by the action of water and leads to soil salinization. Better to take granite or dolomite. It is desirable that the fraction of crushed stone be in the range of 2-4 mm.

- Broken brick. Required when installing an open surface drainage system.

- Geotextile. An important element that prevents clogging of the system. It can be woven and non-woven. The first option is ideal for a deep drainage device. The second option is multifunctional, but not necessary. And it costs more.

To complete the storm sewer, they take a geotxtile with a density of 100-200 g / m2.

Installation steps

- Ditches are dug to a given depth for laying pipes or trays. The soil in them is carefully compacted.

- A layer of sand 7 cm thick is poured into the bottom of the trenches and tamped well.

- The next layer of the drainage roll is fine crushed stone. Its layer is 10 cm-15 cm.

- The geotextile is mounted in such a way that its free edges protrude 20 cm at both ends.

- Pipes are laid on the fabric and wrapped in filter material.

- A layer of rubble is again poured on top.

The finished communication is covered with soil. But it is forbidden to ram the ground. Over time, she will sit down by herself.

Common mistakes when installing drainage

When arranging drainage on the site, novice masters often make ridiculous mistakes:

- Lack of geotextile on drains in clay soil. In this case, the pipe will become clogged with sand over time. A blockage will occur in the sewer, which will require elimination by flushing or cleaning the line.

- No slope towards the receiver. As a result of such a construction blooper, on the contrary, water will stagnate on the site, instead of freely flowing into its lower part.

- Insufficient depth of drains. If this parameter is neglected, all communication efforts will be in vain. Water simply will not completely drain from the site.

Eliminating such errors allows for effective communication.

Drainage system operation and maintenance

The finished drainage line on the site requires maintenance and adherence to the principles of its operation. Regularly perform the following activities:

- Once a season (in spring and autumn), they check the operability of the drainage system through the inspection wells. If you notice that water stagnation has formed in one of the sleeves, you need to clean this area.

- Every 4-6 years, a major cleaning or flushing of pipes is carried out. To do this, use special installations with accessories for them (nozzles, brushes, etc.).

It is advisable to lay pipes, the diameter of which allows filling the system by 30%. In this case, even if the line freezes, it will not break from temperature extremes.