Drainage pumps are in great demand, due to the multifunctionality of the equipment. The main task is to produce forced pumping of waste and rainwater from reservoirs, swamps, reservoirs, etc. There are many models of float drainage pumps of different modifications, some of them are low-power, others are designed for industrial work.

Application area

With the help of a pump, the main purpose of which is to drain, you can implement the following list of tasks in everyday life and industry:

- pumping liquid from natural swamps, reservoirs;

- pumping out liquid from flooded places or premises after heavy precipitation, raising the level of groundwater, as well as melting snow;

- pumping contaminated liquids from one reservoir to another;

- pumping water from pits and trenches that were created during construction;

- cleaning the bottom of wells and mines from pollution;

- drainage of areas in the lowlands.

The equipment is quite versatile in use, since it allows you to perform a large amount of different work.

Principle of operation and device

Power, performance and service life depend on the quality of the oil seals, which are designed to airtight the electric motor. In expensive models, they are made of ceramics, and the body is made of cast iron or stainless steel, which are characterized by high resistance to mechanical stress and the formation of corrosion (rust).

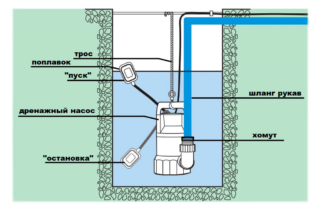

The pumping station is controlled by a float switch, which automatically starts and stops the drive. It is a plastic box with an electrical switch and a steel ball inside.

The principle of operation of a submersible pump with an internal float is that the pumped-out liquid enters the functional chamber, where, under the influence of pressure and turns of the moving wheel, it rises up, cooling the drive.

All drainage pumping stations with an automatic float switch are divided into several groups depending on their location.

- The submersible pump has a sealed casing, which allows it to be operated in a humid environment. Almost silent during operation, all models are powerful and efficient. If the integrity of the hull is violated, it is extremely difficult, and sometimes even impossible, to return the unit to operation. Internal parts are often dirty, so they need to be washed regularly.

- Vertical models have a vertical float switch. Automatically pumps fluid out of confined spaces. As a rule, such equipment is used to drain out of order pipelines. They are also used as conventional drains.

- Internal float units include PVC pipes which are submerged in the borehole, the body must remain on the surface of the soil.The advantage of the pumping station is that it is easy to install, use and maintain. But during operation, this type of drainage pump makes a lot of noise.

- Fecal pumps pump liquid from cesspools and septic tanks. The advantage of the equipment is high power and performance. The device is equipped with an additional part that crushes the waste. Fecal pumps are surface and submersible.

The device of a drainage pump with a float for all varieties may differ slightly, therefore, the connection diagram will also differ, so you first need to read the operating instructions or consult a specialist.

Features of installation and use

Before installing a drainage pump for dirty water with a built-in float switch, it is imperative to measure the level of current that the unit consumes per unit of time. It must be below the acceptable level. Experts advise to carry out installation directly in the recess.

To install, you need a small weight (it is included in the kit) and a cable:

- The weight is attached to the cord, after which you need to determine the stroke of the float.

- With the help of a latch, it will be fixed.

- The cable is fastened from the outside.

- The switch is connected to the pump.

Installation work should be carried out only on condition that the possibility of the float hanging or snagging inside the tank, well, etc. is excluded. If you need to place several floats at the same time, they are placed in a special rod. For this, a plastic pipe is used.

For correct installation, you will need to set, adjust and place the floats so that their working radii do not intersect.

The number of float switches used depends on the drain pump model and the control panel installed. The number of start switches and the number of additional elements also play an important role.

Criterias of choice

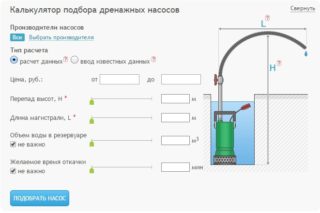

To purchase a drainage pump that, due to technical limitations, will not be useless, you need to meet the requirements and efficiently perform the tasks assigned to it. When buying, take into account the following nuances:

- You should not buy a pump that is too powerful, this is reflected in the amount of electricity consumed. It will heat up quickly. When working "idle" parts wear out faster. Typically, drainage pumps intended for domestic purposes operate on a regular 220 Volt network, the power is 400 W.

- It is necessary to take into account the coefficient of the created fluid pressure at the outlet. It is usually measured in meters of water column, in bars or technical atmospheres. The pressure should ensure not only the rise of water to the surface, but also help to overcome the hydraulic resistance of horizontal pipes.

- The maximum immersion depth of deep drainage pumps.

- A productive water station depends on the speed of pumping water.

- Not all equipment is designed for pumping liquid with solid impurities of large size and high concentration.

When purchasing equipment, you need to carefully study the features of operation and maintenance. The following materials are used for the production of modern pumping stations:

- Plastic is the most budgetary option, the service life of which is relatively short.

- Stainless steel is a durable material that is resistant to mechanical stress. The service life usually exceeds 10 years.

- Cast iron is a high-quality material, but it is used less often for the manufacture of cases, since it is heavy and expensive.

Most often, drainage pumps are made with a plastic casing and a steel wheel. Such models combine high quality and affordability. Recently, pumps with impellers made of polymer have been introduced to the market, they are even cheaper than their counterparts.

It is recommended to purchase drainage pumps with a float from authorized representatives or in specialized large stores. When making a purchase, they check the availability of components, documentation and study the terms of the warranty.