Drainage pumps have many configurations and are in demand in many industries, construction and agriculture. With their help, it will be possible to build a water supply and sewerage system in country and private houses, as well as pump out water in the lower rooms and basements during flooding.

Purpose and scope

Drainage pumps are most in demand for domestic purposes, construction and industry. In everyday life, they are used for pumping liquids from large containers, providing water from wells and wells, for watering plantings in personal plots.

In industry, they are used to regulate the water level in ponds and reservoirs, they irrigate large areas, pump out waste, and also supply water to cool large production units.

In construction, they are in demand, since they clean the pits, control the level of sewage and wastewater, and pump out underground (ground) water.

Types of pumps, principle of operation and device

- submersible units;

- surface equipment.

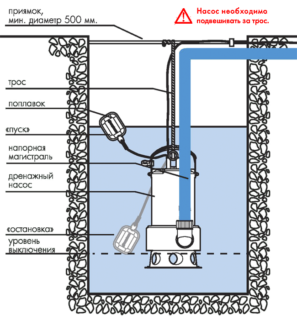

The latter are installed on the surface of the earth near the place of water intake; a special suction pipe is installed at the bottom of the well tank. The float mechanism necessary for the correct functioning of the water system is mounted at a low height from the bottom, and it automatically turns on or off the system depending on the water level in the tank.

Surface pumps have their own advantages and disadvantages. Key benefits include ease of use, maintenance and installation, and portability. Of the shortcomings, only one can be distinguished - the suction depth rarely exceeds 10-12 meters, provided that the depth of water in some places can be 30 and 50 meters.

If we talk about submersible analogs of surface pumps, then for operation they must be immersed in a container with pumped out liquid. As a rule, when used at home, it is installed directly on the bottom, using a special stand that prevents the ingress of silt, small algae, sand and other impurities. Through the filter, the liquid enters the housing, and the float sets the required operating mode.

Compared to surface equipment, submersibles are more powerful and productive, capable of pumping liquids even from great depths (powerful industrial units operate at a depth of 100-150 meters).

Principle of operation and device

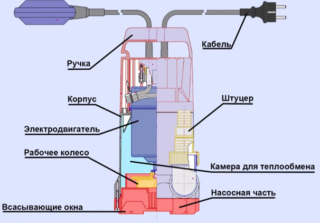

The pump body is made of metal or plastic, in which the working units are located, ensuring high performance of the device. An impeller with a spiral impeller is installed on the motor shaft, and the electric motor is located in a separate sealed metal casing. The lower part is equipped with a special grate through which the sucked liquid flows. The size of the holes is calculated according to the permissible diameters of solid impurities in the liquid, with which the unit is able to work without loss of power and productivity.

Each model of the drain pump is equipped with a float switch that turns off the unit if the water level in the well, pit and other tanks is low. Also, the task of this integral segment of the device is to protect the engine from overheating.

Criterias of choice

When choosing a drainage pump, you need to pay attention to the working conditions, performance, power and other technical features of the selected model.

Pumped media characteristics

Before buying a pump, you need to analyze what kind of liquid it will have to pump out, with what level of pollution and temperature. The water should be relatively clean, free from high concentrations of silt, sand, algae and stones.

Submersible pumps must be stable on the bottom surface. Therefore, the equipment is preliminarily placed in a vat or container of the appropriate size, on a special tiled base. Each model is designed to work in a specific environment.

According to the degree of pollution of the pumped out water, all pumping drainage equipment is divided into the following groups:

- For clean liquids or slightly contaminated liquids: the permissible diameter of solid particles must not exceed 5 mm.

- For moderately soiled water: permissible solids size 25 mm.

- For rain, melt or heavily contaminated water: the size of large particles can vary between 25-38 mm.

It is necessary to pay attention not only to the size of solid particles, but also to the chemical composition of the liquid and its temperature. Aggressive formulations can adversely affect equipment power and performance.

Materials used for manufacturing

The service life of the drainage equipment directly depends on the quality of the materials used in the manufacture. Modern manufacturers most often use plastic or metal for the construction of the case.

In the first case, the cost of the pump will be more acceptable, which in most cases is a decisive factor in the purchase. But plastic cases are less resistant to mechanical and chemical influences than metal ones. Social surveys have shown that plastic often cracks and deforms. In such cases, the pumps can no longer be repaired.

The best material for the manufacture of cases is stainless steel and cast iron, which are able to interact with almost all media.

An equally important detail worth paying attention to is the material from which the pump blades are made. They can be made from a special innovative technical polymer or stainless steel. It is preferable to buy products made from the first material. The impurities present in the polymer make it resistant to mechanical stress and aggressive environments. The most significant drawback is that they cannot be repaired. Metal blades wear out faster and must be replaced, so their cost is lower.

Circuit breaker type

Most models of modern equipment are equipped with automatic switches that start the mechanism when the water level rises to a predetermined level.

According to this principle, devices are:

- Float. The most durable, simple in design and budget segment of the device.

- Built-in electronic sensor. It is complex and expensive.

Automatic shutdown of the pump prevents its "idle" operation, which threatens with serious breakdowns and rapid wear of parts.

Drainage pump installation

Before installing the unit, you need to check the direction of rotation of its station. It is necessary to connect the equipment to electricity and measure the flow.Then disconnect the power supply, replace the phases and plug the pump back into the socket. The final stage is to compare the two numbers, the option with a larger value will be correct.

After the rotation has been checked, it is necessary to place the device on a flat surface and connect it to the mains.

Most drainage pumps are designed to be operated in an upright position. To ensure this, it is important to mount a stable retainer on the handle of the float switch.

The downhole / submersible device must be installed on the bottom of a tank, well, etc. A filter is pre-equipped to prevent the ingress of silt, sand and other contaminants into the body. The water station is best installed on metal leaves or bricks.

Popular models of drainage pumps

In the Russian market, the following models are in great demand among buyers:

- Wilo Drain T. M. 32 / 7-10 m is a small-sized submersible pump designed for draining various tanks. In automatic mode, it controls the water level and is protected from overheating. The maximum pressure from the tap will be 7 m, the productivity, subject to all operating rules, reaches 10 cubic meters / hour. Manufacturer Germany.

- Karcher SDP 5000 is a high-performance equipment made in Germany. In a short period of time, it is capable of pumping large volumes of liquid, the permissible temperature is 35 degrees. The capacity reaches 5000 l / h, the maximum head is 8 m.

- Vortex DN900 is produced in Russia and is a submersible pump with a power of 900 W and a throughput of 15.5 cubic meters per hour. Designed for liquids with a maximum particle size of 35 mm. The head reaches 8 m. Additionally, the equipment is equipped with an automatic shutdown mode and overheating protection.

- Makita PF1010 is one of the few surface pumps that is in great demand. The equipment is manufactured in Japan and is famous for its high performance and reliability. Designed for pumping contaminated water with solid impurities up to 35 mm in size. It is often used for irrigating plantings in the country, pumping liquids from basements and other rooms. Productivity, subject to all the rules of use, reaches 14.4 cubic meters / hour, the maximum immersion depth is no more than 5 m. The head reaches 10 m. Additionally, the model is equipped with an automatic shutdown function, which prevents the likelihood of dry running when the required water level drops.

The prices of submersible drainage pumps for dirty water fluctuate widely, it depends on the configuration, model equipment and manufacturer. In Russia, the cost of budget models starts from 1.5-2 thousand rubles.

Drainage pumps are an irreplaceable thing in the household. By purchasing it, you should not save money, since equipment of dubious quality quickly breaks down, which requires additional costs.