The market offers many technical gadgets that make life easier for the owner of the house, especially in such unpleasant matters as cleaning the sewer. To avoid using a bucket to empty an overfilled sump or sump, use a drain pump specially designed for this type of work.

What are drainage sewer pumps used for?

Autonomous sewerage systems, which are used to equip estates and houses in cottage settlements, need regular maintenance to ensure continuous operation. To prevent the storage tanks from overfilling, it is necessary to periodically remove wastewater or bottom sediment from them.

For the maintenance of the sewage system, specialized drainage units have been developed that are capable of pumping out fecal water containing solid inclusions and fibrous masses from the settling tank.

Purpose and scope

Designed for pumping dirty sewage water, drainage pumps are multifunctional helpers that make it easier to carry out a variety of tasks in the home or field. They are adapted to work in aggressive media, designed to pump out viscous liquid media containing solid particles. With their help you can:

- remove wastewater from septic tanks or storage collectors;

- pump out water from domestic sewer, storm water wells;

- drain basements flooded by rainwater, basements;

- urgently remove water when an apartment is flooded, a breakthrough of heating batteries or water pipes;

- replace water in artificial reservoirs.

The drainage pump is convenient for household use to water the lawn, garden trees, or garden plants by pumping water from a nearby lake or river.

Main selection criteria

To choose a drainage pump for sewage in a private house, you need to pay attention to the following parameters: the presence or absence of shredders, power, installation method. The reliability of the sewer system is ensured by a properly selected device.

The choice of technology is determined by the operating conditions. In order to comply with the necessary requirements, it is necessary to consider:

- septic tank scheme;

- the immersion depth of the mechanism in the tank

- the length and diameter of the hose from the point of fluid intake to the point of discharge;

- the power of the drainage pump for the septic tank;

- the required voltage of the mains is 220 or 380 volts;

- created water pressure and productivity per unit of time;

- temperature and composition of the transported liquid: diameter of solid inclusions, degree of aggressiveness of impurities;

- engine cooling system;

- body material and internal parts;

- the reputation of the manufacturer;

- ease of maintenance and ease of installation;

- noise level.

Before going to the store, write down the parameters that are optimal for you and take the list to the store.

Types of pumps

Devices are of the vacuum type, pumping or pressure. Toilet drain pumps with knives are also distinguished.Design features are determined by the area of application, the permissible level of pollution, the maximum temperature of the discharged wastewater.

The liquid in the sewer is a chemically aggressive environment, therefore, the cases of specialized pumps are made of especially durable materials:

- stainless steel;

- thermoplastic;

- bronze;

- cast iron.

Ease of operation and maintenance of pumps depends on the installation method.

- Superficial. Installed next to the tank. Medium power. The body is plastic, as there is no contact with an aggressive environment. The noise level is high. Easy to maintain.

- Submersible. Installed on the bottom of the tank. Big power, high performance. Autonomous: on-off adjustment is performed by a float switch, which, with an increase in the liquid level, floats up and turns on the engine, and when the level decreases, it goes down and turns off. The body is made of stainless steel or cast iron. Quiet. For service, it must be lifted to the surface.

- Semi-submersible. The engine is located on the surface on the platform, the suction bell is on the bottom. Noisiness is average. The service is simple.

Experienced owners recommend installing two float switches in series on a submersible pump, one above the other - this is an inexpensive but reliable way to protect an electric motor from burnout.

Principle of operation and device

Drainage pumps are designed to pump a non-uniform liquid from a source to a storage tank. To prevent loss of power, the unit is installed as close as possible to the place where there is an excess of water. Modifications of drainage pumps allow the presence of solid particles in the solution: the particle size should not exceed 50 mm for household devices, 120 mm for industrial devices; the optimal volume of inclusions is not more than 10%.

To work with viscous liquids containing very small inclusions in size, drainage pumps with a grinder are used. The device is more efficient but more expensive.

The design includes the following parts:

- electric motor;

- a shaft with an impeller for moving the liquid inside the device;

- pumping unit;

- intake pipe, the diameter of the holes of which determines the size of the passing solid particles;

- float switch that automatically changes the operating mode depending on the liquid level;

- body.

A working electric motor with the help of an impeller creates a rarefied atmosphere in the compartment of the pumping unit. The centrifugal force and the pressure drop provoke the movement of the viscous liquid towards the discharge pipe and further into the accumulator. Large volumes of clean water are pumped in the same way.

Installation steps

- placing the engine outside a sewer or drainage well on a prepared site;

- immersion of the receiving pipe to the bottom of the liquid to be removed, the outlet hose - into the storage tank;

- connection to electricity.

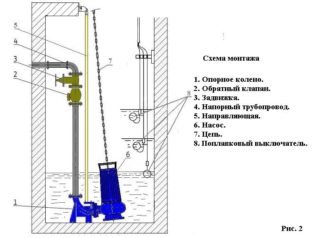

The assembly of submersible and semi-submersible mechanisms must be carried out according to the instructions in compliance with the technical requirements. The submersible pump must be completely installed at a certain distance from the bottom of the storage tank, fixed on vertical metal rails in order to rise to the surface for routine inspection or repair. In a semi-submersible engine, it is located on the surface of the liquid on a special platform, and the pump with an intake is lowered to the bottom of the tank.

It is necessary to pay attention to the quality of the electrical insulation, the tightness of the case and the resistance of the mechanism parts to the aggressiveness of the pumped medium or external influences.

Advantages and disadvantages of drainage pumps for sewage

Different types of pumps have their own advantages and disadvantages.Having determined the most significant parameters for yourself, you can purchase the most suitable device.

| Surface type pumps | Submersible pumps | |

| Dignity | ease of installation and maintenance | no noise |

| versatility | versatility | |

| compactness | small dimensions | |

| mobility | autonomy | |

| low price | ||

| large volume of pumped liquid | ||

| disadvantages | the need for two working hoses | to avoid overheating of the motor, it is necessary to monitor the tripping device |

| noise | ||

| leaky casing |

To avoid stoppages of the sewer system in emergency situations and during periods of scheduled maintenance, experts recommend having a second one as a safety net. The pumps can be located in one or two different, interconnected wells.