To work with contaminated water (pumping out flooded premises, watering from nearby natural reservoirs, draining ravines), it is better to use a drainage pump. Its design allows you to process media with an admixture of large enough particles of debris. And this does not affect the performance of the unit in any way. The Whirlwind drainage pumps have proven themselves well. Domestic products are in great demand among craftsmen.

The device, the principle of operation of the drainage pumps Whirlwind

All units of the Vortex drainage type are centrifugal only. Devices are surface or submersible. Regardless of the type of device, its main working nodes are repeated:

- working and pumping chambers, which are enclosed in one housing;

- motor in the form of a stator with two layers of winding;

- float fuse (for submersible models);

- end seal;

- impeller with blades;

- suction inlet with strainer (mesh size determines the size of the passed particles).

The difference between surface and submersible drainage pumps lies in the principle of their installation. The first ones are mounted near the reservoir. The latter are immersed directly into the aquatic environment.

The principle of operation of the pumps:

- When the engine is turned on, an electric current sets in motion a rotor with working blades.

- The rotating wheel forms a pressure drop in the chamber. As a result, water is sucked in through the inlet.

- The blades activate the centrifugal force, press the liquid against the walls of the chamber and thereby push it up.

- The pressure in the chamber drops again and a new water intake takes place. In this case, the pump does not turn off.

The cyclic pressure drop in the system ensures a stable head and smooth water supply.

Advantages and disadvantages

Among the main advantages of the Vortex drainage pumps, users highlight the following:

- device reliability;

- long service life;

- good performance;

- body tightness;

- resistance of working units to corrosion;

- compactness;

- light weight and mobility;

- the presence of an ergonomic transport handle.

The only drawback of the master is the small length of the electric cable and the need to finish it off.

Model range and technical characteristics

On the market, the Whirlwind drainage pumps are presented in several modifications. Each of them has its own technical characteristics.

Pump DN-300

This is the smallest model of all Vortex units. Consumes only 300 watts. The working units of the device are made of durable polymer resistant to abrasive particles in water. The technical characteristics of the model are as follows:

- productivity - 11 m3 / hour;

- immersion depth - no more than 6 m;

- outlet pipe diameter - 1.5 inches;

- impurity size - up to 5 mm;

- the maximum temperature of the pumped-over water - +35 degrees;

- weight - 5 kg.

The model is equipped with a float switch and overheating protection.

Pump DN-400

This model has the following characteristics:

- power - 400 W;

- productivity - 11.3 m3 / hour;

- immersion depth - 5 m;

- the size of the passed particles is 5 mm;

- outlet pipe - 1.5 inches;

- body material - polymer;

- the maximum temperature indicator of water is +35 degrees.

Like the previous modification, this one is equipped with a float switch and overheating protection.

DN-550N model

Medium-power device, the body of which is made of stainless steel. Engine power - 550 W. Device specifications:

- productivity - 10 m3 / hour;

- head - 8 m;

- depth - 8 m;

- impurity diameter - up to 35 mm;

- outlet pipe - 1.5 inches;

- case - stainless steel;

- weight - 5.85 kg.

The model is good for garden watering and use in the country.

Pump DN-750

Technical data according to instructions for use:

- power - 750 W;

- productivity - 15.3 m3 / hour;

- immersion depth - 8 m;

- head - 8 m;

- admissible size of impurities - 25 mm;

- water temperature - +35 degrees;

- the diameter of the outlet pipe is 1.5 inches.

The main working units of the pump and its body are made of durable plastic.

DN-900 model

This modification also has a float switch and is notable for its modest dimensions. Technical specifications:

- power - 900 W;

- productivity - 15.5 m3 / hour;

- immersion depth - 8 m;

- head - 8 m;

- cable length - 8 m;

- impurity diameter - 35 mm.

No more than 20 switch-on cycles per hour are allowed. The body of the device is made of durable polymer.

Pump DN-1100N

The device is equipped with a powerful 1.1 kW motor. Otherwise, the technical features of the models are as follows:

- productivity - 15.5 m3 / hour;

- immersion - up to 10 m;

- head - 8 m;

- case - stainless steel;

- the temperature of the pumped-over water - up to +35 degrees.

It is recommended not to allow more than 20 switching on of the device per hour.

How to choose a pump

To select the optimal model of the drainage pump, you should be guided by the following criteria:

- Operating conditions of the device. It is necessary to take into account the permissible size of contamination in the pumped water.

- The head of the device according to the instructions. Here it is important to know the depth from which the liquid will rise, and the horizontal length of the hose to the point of water discharge. It is important to consider that every 10 m of the horizontal section of the network is equal to 1 meter of head.

- Unit power. For some masters, this criterion is decisive after the main characteristics.

- Performance. It is especially important when pumping out dirty water from flooded premises. If the water arrives faster, the pump will simply not cope with its functions.

Additionally, masters pay attention to the cost of equipment and the availability of protective options.

Installation principles

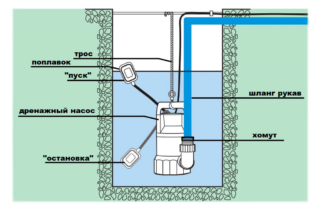

Installation of a submersible drainage pump is not difficult for the master. The works are performed in the following sequence:

- A discharge hose is attached to the outlet pipe using a fitting. It is important to ensure that the connection is tight.

- Check the electrical cable for integrity, no damage.

- The pump is lowered into a reservoir or flooded room so that it rests on the bottom. When installing the device in a pond / river, a solid solid foundation must be placed under it so that the inlet pipe does not pull sand from the bottom.

- It remains to connect the unit to the network.

If the device pumps out / supplies dirty liquid without interruption, then the pump is installed correctly.

Features of operation

Vortex submersible drainage pumps do not require complex maintenance. But the manufacturer recommends the following:

- It is forbidden to distill any chemicals and oils through the working chamber of the pump.

- Avoid ingress of metal particles and fibers into the pumped water.

- The unit is lowered into the environment to be processed only when it is not connected to the mains. Electricity is supplied after the dive.

- It is advisable to store the pump in a warm room, and well dried beforehand.

Subject to the recommendations given, the unit serves without breakdowns.

The prices for drainage units in Moscow are quite acceptable. Depending on the model, the cost of the device ranges from 2,200 to 5,500 rubles.

Owner reviews

Judging by the reviews about the Whirlwind drainage pump, the units fully justify their cost and the declared technical characteristics.

Roman, 29 years old. At the dacha in the spring, the basement is often heated. And in the summer rainy season the same problem. I had to urgently look for an inexpensive drain pump. Whirlwind DN-300 really helps. I have been using it for two years already. No complaints. I threw it into the water, pumped it out, removed it. Do not grease, do not dry additionally. Fully justifies its price.

Ilya, 32 years old. The pump ДН-750 was initially taken for irrigation. I draw water from a nearby pond. The distance from the garden to the reservoir is 30 meters. When immersed at 3 m in water, the pump pumps normally. In about 1.5-2 hours, I completely flood 4 acres of plantings in the heat. I put a boardwalk 5 cm thick under the unit so that the sand does not suck. The second summer will be like a pump in use. Recommend.

Nick, 35 years old. For me, the DN-1100 model became a godsend when I bought a house at the very bottom of the village with a high groundwater table. In order not to build a complex drainage system yet, I use this pump. When the ravine is completely filled, I throw the unit into it and pump out the water to the end. I dump it into a pond nearby. A special brick platform was laid under the pump. The float will always shut off the pump itself when the water is completely pumped out.

Yura, 42 years old. Recently, it was necessary to completely pump out the drainage well of the septic tank, since its bottom was apparently silted up and the water stopped leaving. I asked a neighbor for a pump Vortex DN-500. I pumped out all the water in just an hour. I am satisfied. I understand that you need to take one for yourself. You never know what else with the well.