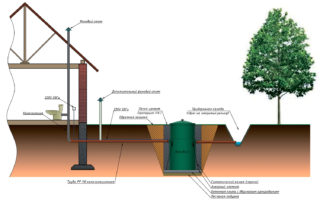

The fan riser in a private house is designed to compensate for the vacuum that occurs when a large volume of waste is drained. With its help, the gases accumulated in the pipes are removed, as a result of which the device got its name, which is translated from English as "funny". It is the connecting element between the sewer well and the atmosphere.

The device and principle of operation of the fan pipe

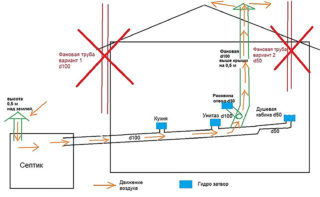

The fan pipe ensures the flow of air into the vacuum zone without disrupting the hydraulic seal system. The main devices guilty of the appearance of a local area of low pressure are toilets and washing machines that drain water under pressure, as a result of which the lumen of the vertical sewer riser is completely blocked.

The fan pipe prevents the appearance of a vacuum, filling the vacated space with air. The second purpose of the device is to create a draft for the removal of accumulated gases.

Manufacturing material

Since the outlet of the riser is one of the components of the intra-house sewer system, the same materials are used for its production as for other wiring elements. Mostly cast iron and plastic pipes are used. The former have high strength, but when defects appear, they begin to deteriorate under the action of corrosion. In addition, it is quite difficult to strengthen a heavy cast iron pipe in an upright position.

An alternative option is to use polymer pipes. They are durable and lightweight, do not corrode and have a low cost. Making the installation of the sewer system using plastic pipes and fittings is much easier than connecting cast iron elements. The advantage of polymer products is in a smooth inner surface, which excludes siltation of the pipe system. Cast iron products are rough on the inside, which is one of the reasons for operational blockages.

For normal operation, the diameter of the waste pipe must correspond to the largest section of the pipe connection. According to the rules of SNiP, the toilet bowls have the largest diameter of pipes for connecting to the drainage system: 100-110 mm, therefore, the outlet pipe must have a section of the same size - 110 mm.

Rules for installing a fan pipe in a private house

According to current building codes, pipes must be installed starting from two-story structures. However, experts believe that this device in a one-story individual building will also ensure the proper functioning of the drainage system. If your home has a toilet, sinks, shower, washing machine and dishwasher, you need a drain pipe.

Since the risk of a complete overlap of the section depends directly on the volume of incoming drains, there is no need to bring the riser to the roof for a country house, due to its short-term use and the minimum number of plumbing fixtures.

Common installation errors

The installation of a fan riser does not cause difficulties and is carried out during the installation of the internal sewerage system. If the drains of all plumbing devices have a tie-in into one riser, one pipe is enough. Otherwise, when the plumbing fixtures are remote from each other, it makes no sense to pull the pipelines in order to connect them to one fan riser, since the thrust decreases with the increase in the length of the horizontal sections. In this situation, each sewer riser is mounted with an outlet to the roof and supplied with a weather vane.

A significant temperature difference, especially in winter, contributes to the effective removal of gases, since their temperature in the heated room is higher than the outside air temperature.

The vertical installation of the fan riser is carried out using clamps attached to the wall. They securely fix the device. For sound insulation, the riser is covered with a mineral sheet in rolls or slabs.

Inference is done in 2 ways:

- through the riser;

- with the manufacture of a pipe on the roof of the structure.

The installation of the latter is carried out in accordance with the requirements:

- with a flat surface, the height should be 0.3 m;

- above the pitched roof not less than 0.5 m;

- when using the roof for household purposes, the permissible height of the funnel must be at least 3 m.

To prevent the smell of sewage from entering the living space, the outlet of the riser is located at a distance of at least 4 m from the windows. Decorating it with decorative elements will lead to condensation of vapors on their surface. In winter, this is fraught with icing of the fan pipe, which, in turn, narrows its lumen and reduces the efficiency of the device.

Another installation error occurs when the homeowner tries to move the pipe outlet to a secluded spot on the roof to give the home a more aesthetic appearance. All horizontal movements reduce the air velocity.

Experts do not recommend making a fungus on top of the pipe so that the riser hole does not block when it freezes.

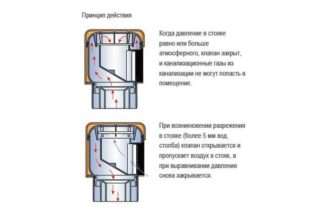

The check valve prevents backflow of gases and protects the riser from blockages. However, the vacuum valve is not able to replace the drain pipe, especially when the liquid in the hydraulic locks dries out.

Users often wonder how to make a sewer outlet if the house is already built and tiled. Installation between the house and the septic tank will not give the desired effect. During installation, it is recommended to bring the riser as close to the ridge of the roof as possible, so that when the snow melts it does not demolish the fan element, as it happens if it is installed under the overhang.

The correct solution is to exit through the roof. In this case, you need not to get into the rafter crate. The sewer outlet in the middle lane should be insulated so that it does not freeze over in winter in severe frosts. With the help of a drill from the side of the attic, a hole is outlined with an exit to the outside. The inner riser must fit into the protrusion of the outlet element. It is very unlikely that it will directly fall under the hole made in the roof, therefore, a corrugated pipe is used as a connecting element.

In order for the penetration to be hermetically sealed on the roof deck, special elements are used that are placed under the outlet. Around the marked hole, the flooring is cut out according to the stencil. In the place where the waterproofing film will be damaged, a water seal seal is placed, gently bending it with your hands along the metal profile. This will prevent water flowing from the roof from entering. A special silicone sealant (without vinegar) is applied between the seal and the roof, self-tapping screws are screwed on. The base of the penetration is attached to the roof, and a sewer outlet is mounted on top.

If the site has a septic tank with biological treatment using microorganisms, the supply of fresh air through the drain pipe is vital for them.