To reduce labor costs and the cost of sewerage, builders are increasingly giving preference to corrugated pipes made of various polymeric materials. In terms of strength and service life, they practically do not differ from steel or cast iron, have a lower cost, and are easier to fit together.

Scope of corrugated sewer pipes

Corrugated flexible plastic pipes for sewage are used in the same cases as conventional ones, but the degree of reliability is higher. To equip a suburban autonomous sewerage system, a storm drain, to conduct a water supply into the house - all this can be done using corrugated pipes.

The corrugated surface is especially relevant where there is a danger of damage to the mainline due to the geological features of the terrain - in the mountains, on the banks of the river, in seismically active zones. Ground movements - landslides, earthquakes - can destroy an entire water supply or sewerage system in a matter of minutes. Linear tension is zero if soil is caught between the bulges and holds the line in position.

Ring stiffness is needed if the pressure in the system is not constant. Water hammer often leads to pipe rupture. Raised ribs on the entire surface of the product contain water pressure and prevent bursting.

Types of corrugated pipes

Corrugated plastic products are used for indoor and outdoor sewerage. If the internal wiring can be carried out using less durable pipes, then for external work there are more varieties:

- lungs;

- heavy;

- superheavy structures.

Lightweight corrugated products by their properties are suitable for outdoor sewerage or water supply in stable ground. Their density is less, the walls are most often single-layer. They are also used when laying electrical cables. They are flexible and elastic, but reliably protect the cable hidden inside from damage during excavation work. Since lightweight corrugated pipes are afraid of ultraviolet radiation, they are not recommended for use outside the building or on the surface of the ground. Distinguish according to the degree of rigidity:

- SN 2 marking is intended for laying to a depth of no more than 2 meters - these are single-layer products;

- SN 4 - up to 3 meters;

- two-layer SN 6 - up to 4 meters;

- two-layer SN 8 and SN 16 - up to 10 meters.

Heavy corrugated pipes are used in moving soil for laying at great depths. If the depth is less than recommended by the specification, the pipes will last longer due to the reduced load. They are used for urban communications that are located near pedestrian roads or highways. To prevent the products from clogging up with soil and stones, they are produced in a protective shell made of geotextiles.

Extra-heavy pipes are made in two layers and are designed for burial under railway rails or high-traffic roads, where the level of ground pressure and vibration is increased. This variety is made without a protective sheath.

By functional purpose

Corrugated pipes are used for various purposes, one of which is to hide electrical communications or lightweight hoses to avoid damage. The density of the material is less, therefore the products are more flexible and elastic.These qualities also depend on the material from which the pipe is made. If necessary, you can carry out repairs in the house, remove the plaster and get a corrugated single-layer hose, replacing it with a new one.

Heavy and super-heavy structures are not designed for frequent replacement - they are laid deeply and for a long time, therefore, the degree of strength must exceed the adverse environmental conditions. In this case, the service life of massive structures will be more than 50 years.

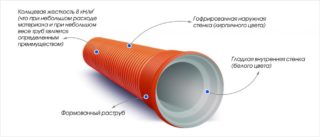

Smooth inner surface ensures fast flow of waste water through the mains. Organic particles do not have time to catch on the walls, so they will not need to be cleaned soon. According to reviews on construction forums, some owners washed the pipes with chemicals for the first time after 10 years of operation.

In heating systems, pipes give the room an aesthetic appearance, as they are painted white.

By properties and material of manufacture

- density;

- thermal conductivity;

- resistance to chemicals;

- exposure to ultraviolet radiation;

- impact resistance;

- fire resistance;

- linear and circular stretching;

- resistance to low temperatures.

Polypropyleneis able to withstand temperatures from - 20 to + 95 degrees, therefore it is used to drain hot liquids in industries.

The material is resistant to chemicals - acids, alkalis, alcohols. The presence of corrosive substances does not change the structure of the inner surface of the walls. Lime and iron ions cannot adhere to smooth surfaces due to the high flow velocity. In the domestic sewage system, the same thing happens with organic matter - it does not accumulate on the walls.

For different purposes, polypropylene is used, reinforced with fiberglass or aluminum foil. This increases strength and durability.

Connect plastic pipes using fittings or welding. In the first case, angle adapters or couplings are used, in the second, pipes are fastened in a straight section with a soldering iron.

Pvc - the most commonly used material in everyday life. It is preferable to use in non-pressure systems, since the material withstands pressure up to 0.16 MPa in terms of strength. Polyvinyl chloride is 5 times lighter than metal, so installation is much easier - you don't even need to use heavy equipment.

Since the inner surface is smooth, organic matter in an autonomous domestic sewage system does not grow on the walls and does not contribute to the reproduction of microorganisms. Therefore, there is no smell in the house and on the site.

PVC is used for arranging a water supply system, since the material is non-toxic and does not support the growth of bacteria. It is safe in internal wiring - does not ignite, does not deform when heated. The only drawback is that it does not tolerate low temperatures. At 10 degrees below zero, it becomes brittle, therefore, before laying in the ground, the pipes are wrapped with heat-insulating material.

For home sewerage and summer water supply, you can use polyethylene... Its elasticity has been proven empirically: when freezing water in polyethylene pipes, they did not burst, but only slightly stretched. The lower temperature limit is 0 degrees.

In ordinary pipes, the temperature of the transported liquid should not exceed 45 degrees, based on the manufacturer's recommendations. But after the experiments, we can say that the products can withstand short-term heating up to 80 degrees and do not collapse.

Different grades of material are designed for different ground pressures. Based on the planned depth of the bookmark, a suitable option is chosen in terms of density, diameter, strength. The number of layers and material modification matter:

- LDPE - high pressure polyethylene;

- HDPE - low pressure polyethylene;

- cross-linked polyethylene.

The pipes are marked in the form of a colored tape, which indicates the purpose for which the product is intended.

Dimensions (edit)

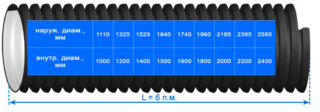

Corrugated pipes have two diameters - inner and outer. In this case, the difference is from 19 to 170 mm, depending on the size of the protruding stiffeners.

The most popular corrugation size for interior work is considered to be a pipe with an inner diameter of 4 to 11 cm. For exterior work, products of a larger diameter with a wider wall thickness and heavy weight are used.

For urban communications, corrugated pipes are used with an inner diameter of up to 103 cm, an outer diameter of 120 cm and a wall thickness of 0.5 cm.

Installation features

It is advisable to carry out all work with plastic products in the warm season, when the temperature outside is above 15 degrees. Corrugated pipes are laid in the ground on a prepared base of sand or reinforced concrete. When connecting by means of a socket, it should be directed in the opposite direction of the slope to prevent liquid leakage.

With the welded method, the wall thickness and the type of welding machine are taken into account. The polymer is heated to the point where it begins to melt, then combined with the other part and held until the plastic dries. With proper welding, a monolithic seam is obtained.

When connected through a socket inside the walls, there will be no scuffs and irregularities, to which large particles will cling. It is advisable to install a manhole at the welding point so that in case of blockage it is possible to cut the pipe and clean it.

You can connect the corrugation with other materials - steel or cast iron. In this case, couplings with fasteners are used.

Advantages and disadvantages

If you need to hide the electrical cable, PVC is suitable for this purpose, because high-pressure polyethylene increases combustion and, if short-circuited in the electrical wiring, can cause a fire.

It is not recommended to use plastic for the installation of surface water supply or sewage systems, since most materials are not resistant to ultraviolet radiation.

Some types of plastic allow moisture to pass through due to the low density of the material, so when buying, you need to clarify what will be transported through the pipes.

When arranging internal wiring in apartment panel buildings, additional noise insulation is required, since plastic well transmits sounds from fluids and drains passing through them.

General benefits for all plastic corrugated pipes:

- have a high degree of strength;

- serve with correct operation for more than 50 years, the maximum period declared by the manufacturer is 90 years;

- good shockproof properties;

- non-toxic, do not release hazardous substances into water;

- easy to install thanks to special devices - sockets;

- light weight in relation to metal and cast iron.

Almost all plastic is neutral to the action of aggressive chemicals - acids and alkalis.

The cost of corrugated products is an order of magnitude higher than conventional plastic pipes. Depends on the length, diameter, wall thickness, as well as the material of manufacture. Prices for two-layer corrugated pipes for outdoor sewerage are higher than for single-layer ones. Reinforced grades will also cost more, as their service life and strength are higher. The most affordable prices are the products of domestic plants for the production of sewer pipes and parts for them.