Residents of multi-storey buildings never think about waste disposal, since there is a sewage system in such buildings. For residents of the private sector, this issue is in the first place when arranging their estates.

What is a drain pit and why is it needed

- Sealed pit. This option is the safest for the environment. All sewage drains, falling into the pit, remain in it and are subsequently pumped out by a sewer truck. The main disadvantage of this option is the need to pump waste out of it.

- Filter pit. This is a drain hole without a bottom. This type of pits is prohibited by law. The thing is that sewage drains are absorbed into the soil and cause great harm to the environment. If, because of such a pit, a water source is polluted, then the organization of such a type of pit can directly harm human life and activities.

- Two-chamber pit. This is the most practical type of drain pit. There are two chambers in such a pit. One of them is sealed, and the second is filtering. The effluent first enters a sealed chamber, where solid particles sink to the bottom, and slightly purified water goes into the filter chamber. From the second chamber, water goes into the soil.

Choosing a place, taking into account the requirements of SanPin

What you need to focus on when choosing a place for arranging a tank for sewage:

- It is important to determine the depth of the groundwater. If there is a likelihood of sewage runoff entering the groundwater, then the arrangement of a sewage tank is prohibited;

- If there is a possibility of floods, it is strictly forbidden to use tanks with filtration holes in the walls of the structure, since there is a high probability of contamination of the environment in case of flooding;

- There should be a possibility of access to the sewage tank for equipment that pumps out sewage from the tank;

- The depth of the pit should be no more than 3 m. Compliance with this condition is necessary for the possibility of pumping out wastewater. At greater depths, this process is greatly complicated;

- The walls of the tank must be insulated to the depth of soil freezing. From above, the possibility of installing a cover must be provided;

- It is forbidden to place the pit on the slopes;

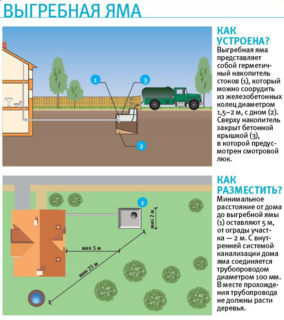

- It is forbidden to equip a sewage tank closer than 5 m from the living quarters and from the fence of neighbors.

Construction methods

When choosing, you need to focus on the conditions of the area and the capabilities of the owner. The main requirement that applies to the material for the manufacture of a wastewater pit is to prevent wastewater from entering the environment. The material used for the installation of the drainage pit must withstand the effects of an aggressive environment, which is the sewage drain. For this reason, it is not advisable to use metal or wood for the construction of a cesspool.

Pits made of concrete rings

- A pit is being dug, the dimensions of which are 80 cm larger than the diameter of the rings used. The bottom of the pit must be tamped. After that, the bottom must be poured with concrete. For simplicity, you can use a ring with an existing bottom.

- After 7 days from the moment the bottom was poured with concrete, concrete rings are installed. The joints of the rings must be sealed with cement and waterproofed with liquid glass.

- The void that appears between the outer side of the rings and the walls of the pit must be filled with the remaining soil. If the temperature at the place of installation of the tank in winter is sufficiently low, then it is necessary to insulate the walls of the structure. The pipes must be laid to a depth exceeding the freezing point of the soil.

- The last concrete ring must be covered with a reinforced concrete slab with a hole for the cover. It is imperative to arrange ventilation to remove methane and sulfur gas from the tank.

- A cover is installed on the floor slab. It will prevent the smell from spreading from the pit. Soil is poured on top of the entire structure to the level of the cover.

Brick pit

Manufacturing consists of the following steps:

- It is necessary to calculate the amount of material that will be needed for manufacturing. For correct calculations, you must prepare a plan in advance. You need to count the number of bricks and the number of rows. You need to divide the height of the wall by the height of the brick. It is important not to forget to take into account the cement thickness of 6 mm. When building a tank, a mortar of cement and sand in a ratio of 1 to 4 is used to connect bricks.

- The next step is to dig a pit of any shape. It is important not to forget to immediately prepare a trench for laying sewer pipes to a depth of 55 cm. The bottom must be filled with cement mortar to a depth of 10 cm. Brick walls are plastered and covered with bitumen mastic. From above, the pit is closed with a reinforced concrete screed. After drying, the screed must be covered with any waterproofing material and covered with soil.

Car tires

- The diameter of the pit is determined. You need to focus on the size of the tires.

- A hole is being dug. If you dig it yourself, the process can take several days.

- The bottom is being equipped. A hole is made at the bottom of the pit for drainage. With the help of a pipe installed in this hole, sediment will be retained.

- The bottom of the pit is covered with rubble 15 cm deep and 85 cm of sand on top.

- The tires are stacked on top of each other and secured. In the uppermost tire on the side, it is necessary to arrange a hole for a drain pipe.

- The joints between tires and pipes must be sealed with a sealant.

- The outer sides of the tires are covered with soil.

- The resulting pit must be closed from above. Planks work well as a cover. It will not be superfluous to protect the lid from the boards with roofing material.

Barrel pit

The arrangement process is quite simple, since the weight of the barrel is small. A special feature of the use of a plastic barrel is the need to fix it to any heavy structure at the bottom of the pit. This is done so that the barrel does not move.The pit for the barrel must be prepared so that the distance between the wall of the barrel and the ground is at least 30 cm. The bottom of the pit must be filled with 20 cm concrete. The barrel is installed on the frozen concrete bottom of the pit. To protect against soil pressure, brickwork can be erected into the walls of the barrel. But this is not a mandatory procedure.

After installing the barrel, the walls are sealed outside with earth. To protect against breakage of the tank, water must be poured into the barrel as the earth is poured. At the end, the water is removed. The last step is to bring drain pipes to the pit.

The option for manufacturing a tank for sewage is selected based on the capabilities and preferences of the owner. Whichever option is chosen, with its correct manufacture, the structure can serve for a long time.