Modern sewer pipes are made of PVC. For ease of installation in a house or apartment, they are produced in various lengths and diameters. To create a reliable wastewater disposal system that does not leak and does not allow unpleasant odors into the room, you can know how to connect its elements.

Required tools

- Special hammer equipped with a wooden or rubber attachment. A standard product will not work - it is easy for them to damage the repaired section of the sewer.

- The cutting tool is a hacksaw or a grinder.

- Adjustable wrenches.

- Depending on the method of joining the pipes, you may need a welding machine, a thread cutter or a hand press.

- Suitable plastic products. When connecting the toilet with a riser, you will need elements with a diameter of 110 mm. To lay the drain to the sink and bathtub, it is better to choose plastic with a size of 50 mm.

- Gaskets, adapters, seals, couplings and sealants.

A shopping list before going to the store must be compiled in advance by checking the work plan.

Preparatory work

Before connecting the sewer pipes, it is necessary to prepare:

- Make sure you have purchased the full range of tools and materials you need.

- Outline the location of communications, prepare a place for work and draw a laying diagram.

- After checking the plan for the placement of individual elements of the sewage system, mark the prepared elements of the sewage system and start cutting out the material.

- For the convenience of joining pipes, the cuts should be cleaned of burrs, dirt and greasy spots should be removed.

- If you need to install metal products, you must apply an internal or external thread to them.

Installation of plastic sewers provides for the installation of inspection hatches. If you neglect this rule, it will be difficult to carry out repair work.

Before connecting the constituent parts of the sewage system, it is necessary to create a drawing of the future system. On a piece of paper, it is worth displaying each plumbing fixture (toilet, sink, bath, shower) and connect them with lines to the riser.

The main methods of connecting sewer pipes

In the bell

- Clean the end of the pipe and the socket from dirt.

- Check for the presence of a rubber seal that ensures the tightness of the system.

- Dry the connected products with a construction hairdryer.

- Lubricate the pipe with silicone compound and insert into the socket. In advance, a mark is made on the elements indicating the depth of introduction.

- Gently pull the pipe back 1 cm.

- Wait until the sealant dries - after 4-6 hours.

It is necessary to cut plastic with a hacksaw with a fine tooth.

With glue

To connect PVC pipes, the gluing method is often used. For such tasks, a special composition is used. Sequence of work:

- Clean and degrease the surfaces to be glued.

- Apply glue.

- Insert the pipes into each other and hold them for 1 minute.

- To increase the tightness of the joint, it is coated with another layer of the composition.

It is important to consider certain tricks of connecting PVC sewer pipes to each other:

- Do not stretch the bonding time longer than 1-2 minutes - the liquid loses its properties in air.

- When connecting products made of polyvinyl chloride, it is recommended to use the flanged method of installing communications. You need to choose cast iron fasteners equipped with a rubber gasket.

- Before installation, the pipe is cut in the connection area. Chamfering is optional, but the cut should be straight. Then put on a free flange at the end of the element.

- The rubber gasket is installed in such a way that it protrudes from the cut by 10 cm. A flange is applied to it, and then it is connected to the counter flange with bolts of the appropriate diameter. Fasteners must be tightened carefully, but not over-tightened.

When connecting sewer elements by cold welding, a special composition is used that dissolves the surfaces of the fixed parts by 1/3 of the thickness. Before soldering PVC products, it is important to consider the temperature and humidity of the air. The work is recommended to be carried out at 5-35 degrees Celsius.

Welding

To weld pipes, you will need equipment that warms up the plastic before joining. The material, heated to certain values, begins to melt. At this moment, the ends of the elements are pressed against each other for several minutes.

The welded sewerage sections form a monolithic system with high tightness. The disadvantage of this method of fixing pipes is the need to purchase or rent an expensive device.

Fitting

You can correctly connect plastic sewer pipes with special elements - fittings. By design, they are divided into straight, L- and T-shaped, tees, extension cords and plugs. This method is often used when installing or repairing small diameter plumbing, or corrugated products.

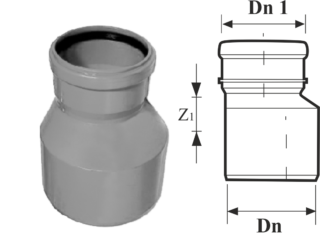

Features of connecting pipes of different diameters

If it is necessary to connect sewer sections of different diameters, it is worth using special adapters. These elements are made from different materials. They are used in water supply, sewerage and ventilation systems.

Transitional elements for connecting pipes of different diameters are divided into concentric (for vertical communications) and eccentric (used in horizontal structures). They are polypropylene, steel, cast iron, polyethylene, brass.

According to the method of installation, adapters are:

- Compression - to create a reliable connection, they need to be soldered.

- Threaded - elements are screwed onto pipes of different diameters.

- Press fittings are designed to create one-piece pipeline assemblies.

Sewer communications often require a joint of pipes made of different materials. For this purpose, a special rubber cuff is used, capable of providing an external and internal transition. In the latter case, the product is inserted into the socket of the cast-iron pipe, which makes it possible to connect a polymer section of the sewage system to it. Such joints do not need to be additionally sealed, so there is no need for special compounds. With an external transition, the pipes are connected without connecting the collar.

Fittings used to connect sewer pipes of different diameters:

- Welded. Set by using a welding machine. They are equipped with threads and seals.

- Glued. To dock them with pipes, you need to use special compounds.

- Threaded. They are threaded and used to connect small pipes.

- A rubber ring is a common type of adapters used during the installation of sewer structures for various purposes. The main advantage of such products is the high tightness of the joints.

When joining the "shell to the shell", the upper parts of pipes of different diameters are combined. The method prevents the reverse flow of wastewater.

Choosing a connection method

The simplest is the method of pipe coupling "into a socket". Even a person who is far from plumbing work can implement it. The bell must be directed in the opposite direction from the one where the water will flow.

Features of different methods:

- Welding is the most difficult way to repair a sewer. For work, you need to have special skills and a complex apparatus. The advantage of this method is the high reliability of pipe fixation.

- The adhesive connection is only durable if the work technology is observed. The surfaces must be cleaned and degreased before the procedure.

- Fittings are secured with O-rings. This connection method does not require special training and can be done independently. An important condition is that there must be constant access to the joints, otherwise it will be problematic to eliminate the blockage.

Knowing the peculiarities of connecting pipes made of various materials, you can independently repair the sewage system in the event of leaks and breakouts.